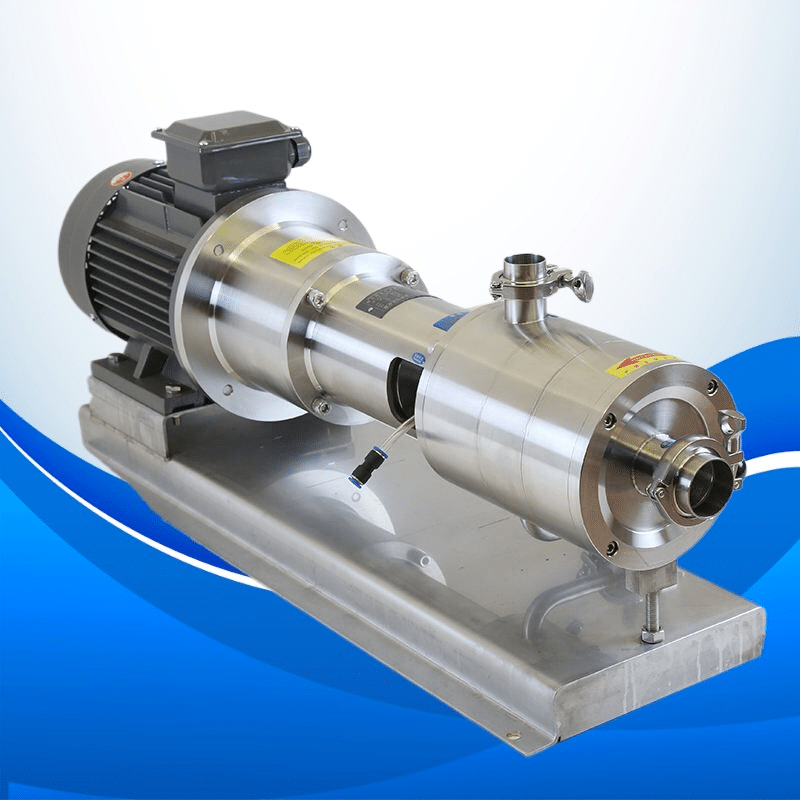

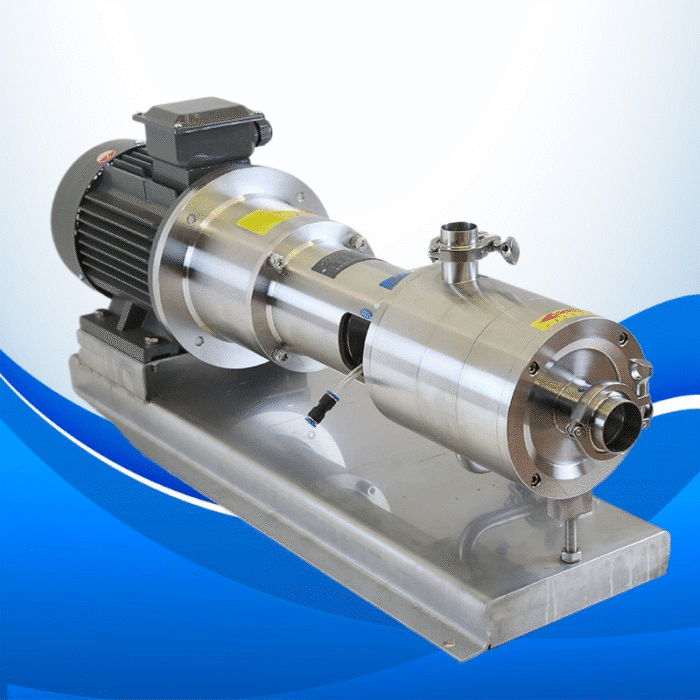

High Shear Pump for Precise Emulsification & Homogeneous Mixing

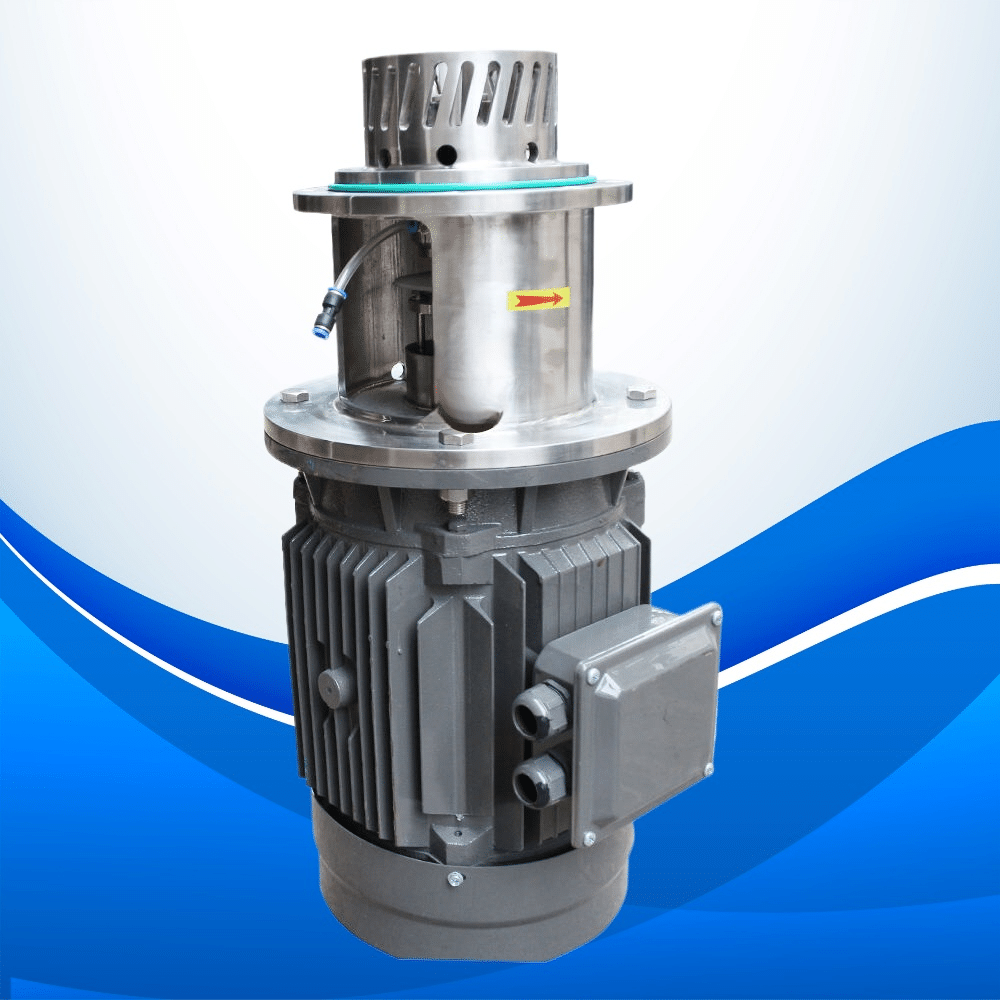

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$2,430.00

Guaranteed Safe Checkout

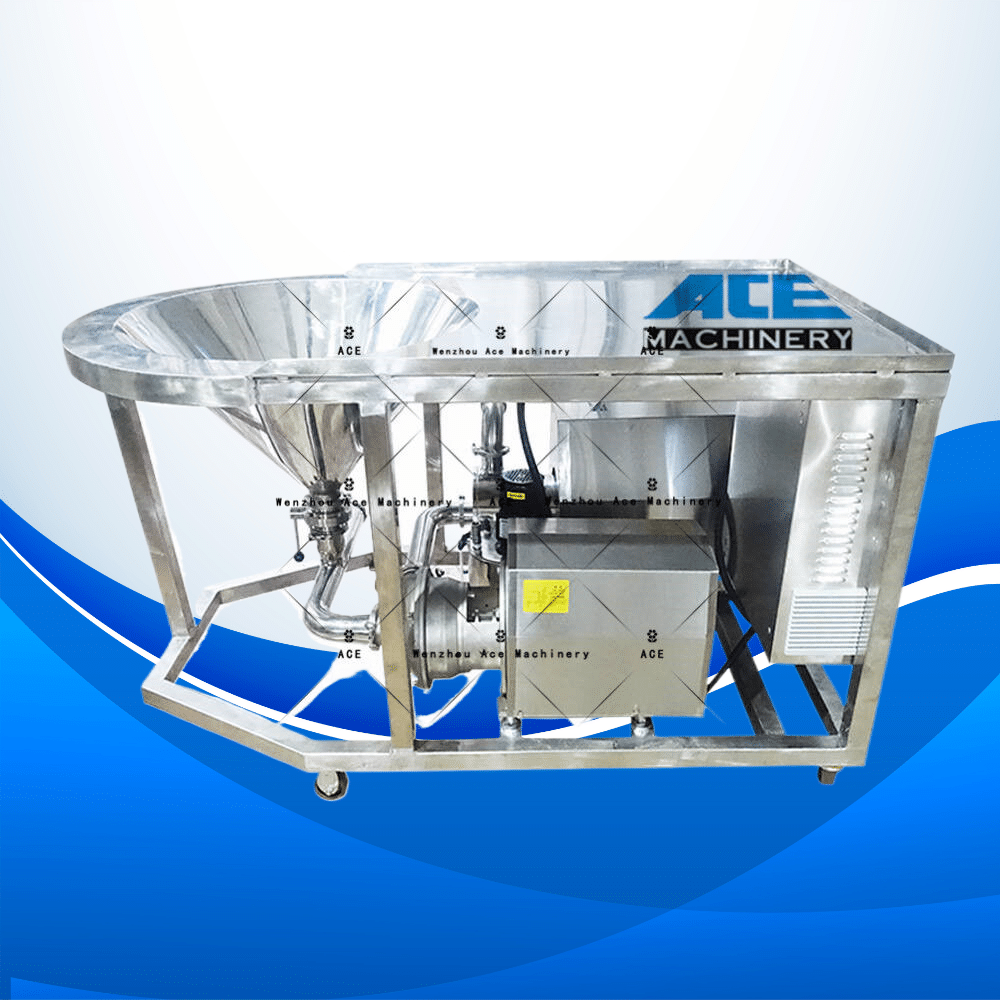

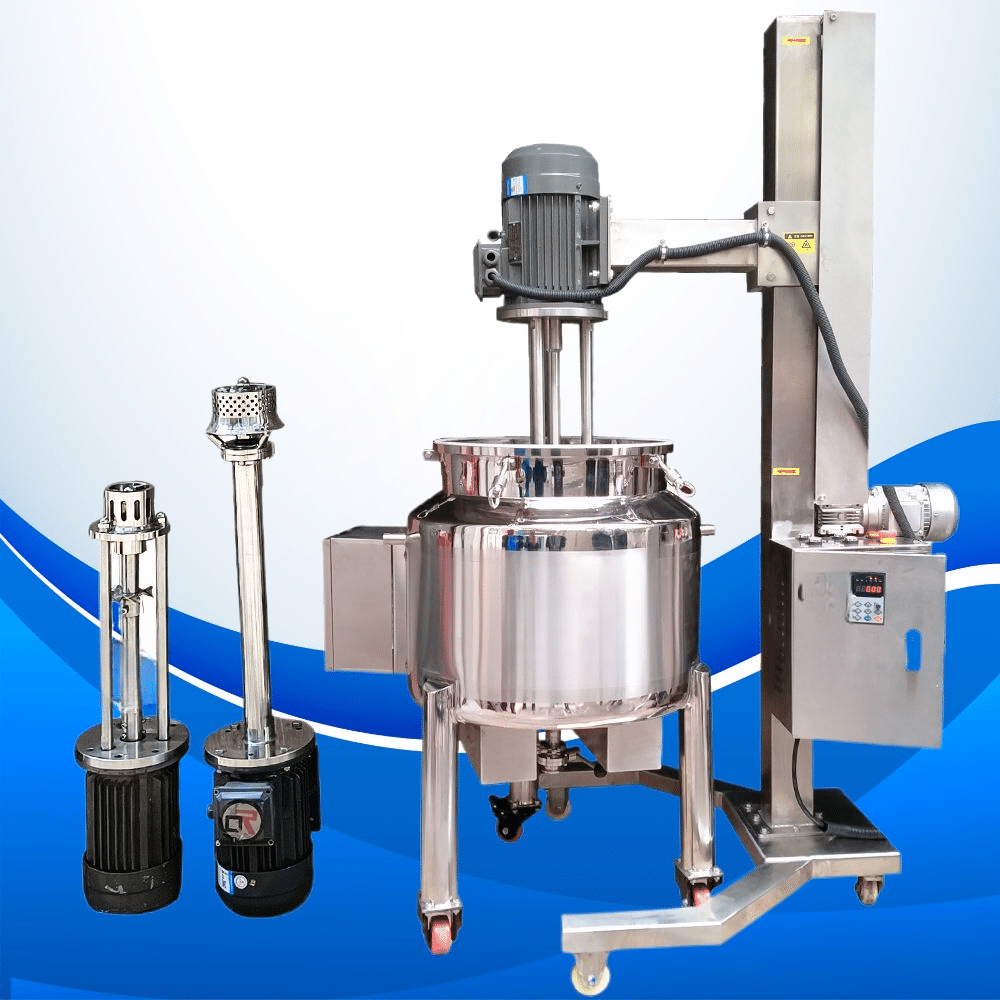

We manufacture and sell the following types of mixers

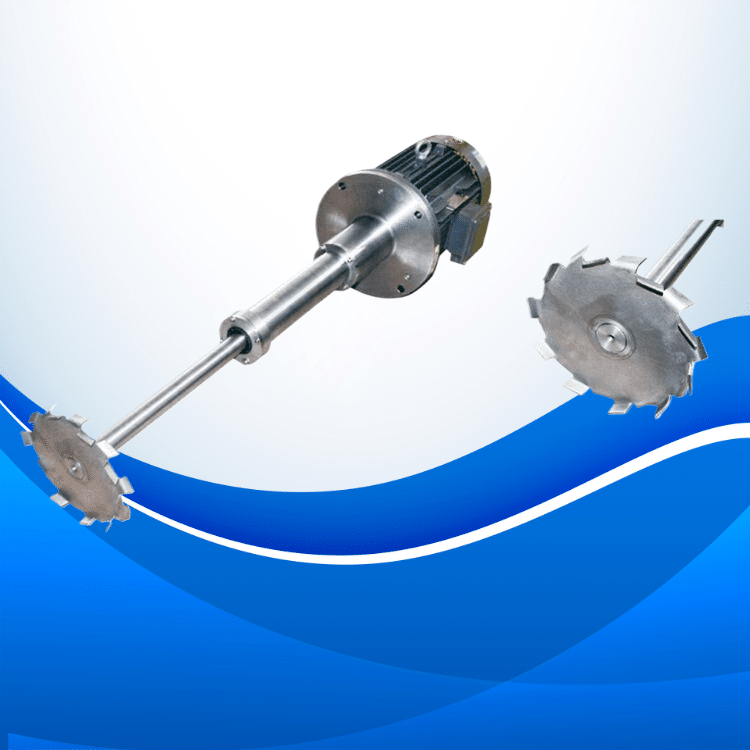

Mix, emulsify, homogenize, disintegrate and dissolve

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

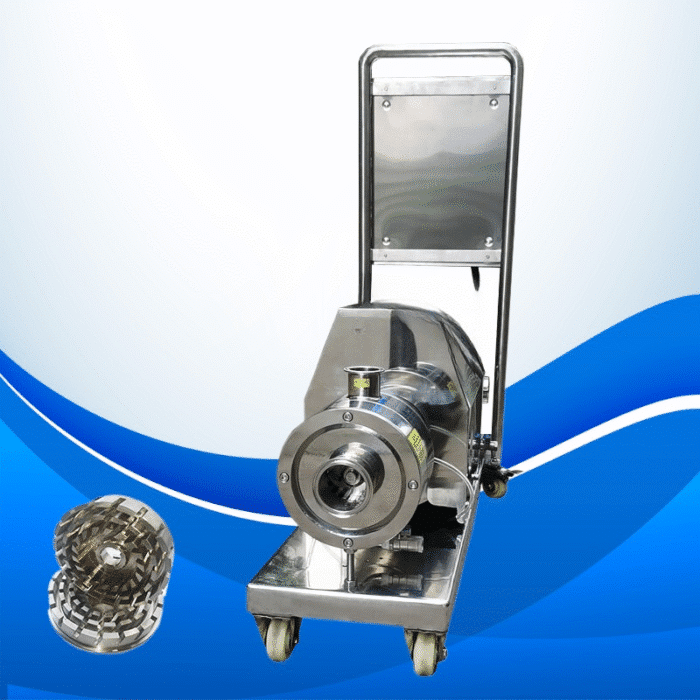

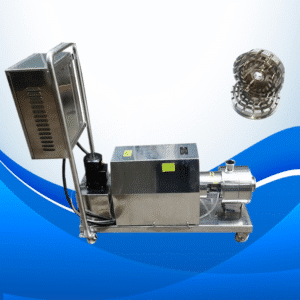

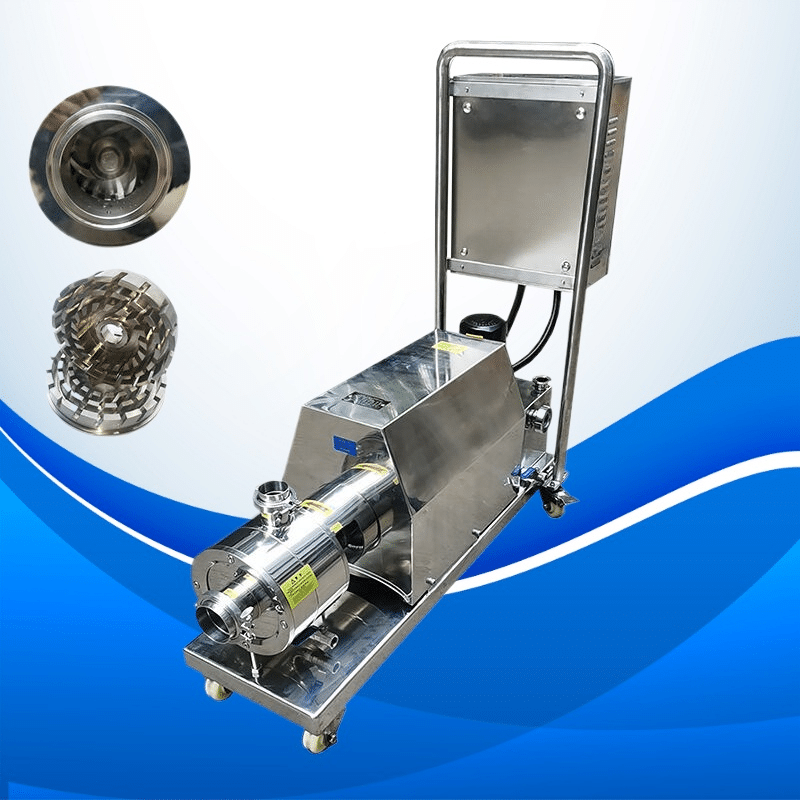

Easy to move and lift

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

Everyday Description of the High Shear Pump

The high shear pump mixes stuff by spinning its blades superfast, so you get smooth dressings, sunny creams, or steady vaccine batches. Built tough, it shows up day after day in:

- Cosmetics: blending soft lotions, rich creams, and healing salves

- Pharmaceuticals: making even suspensions, liquid shots, and clean gels

- Food & Beverage: stirring silky sauces, purees, coffee mixes, and dairy shakes

- Chemical Processing: holding steady dyes, polymer mixes, and custom batch.

Core Advantages

Ultra-efficient mixing

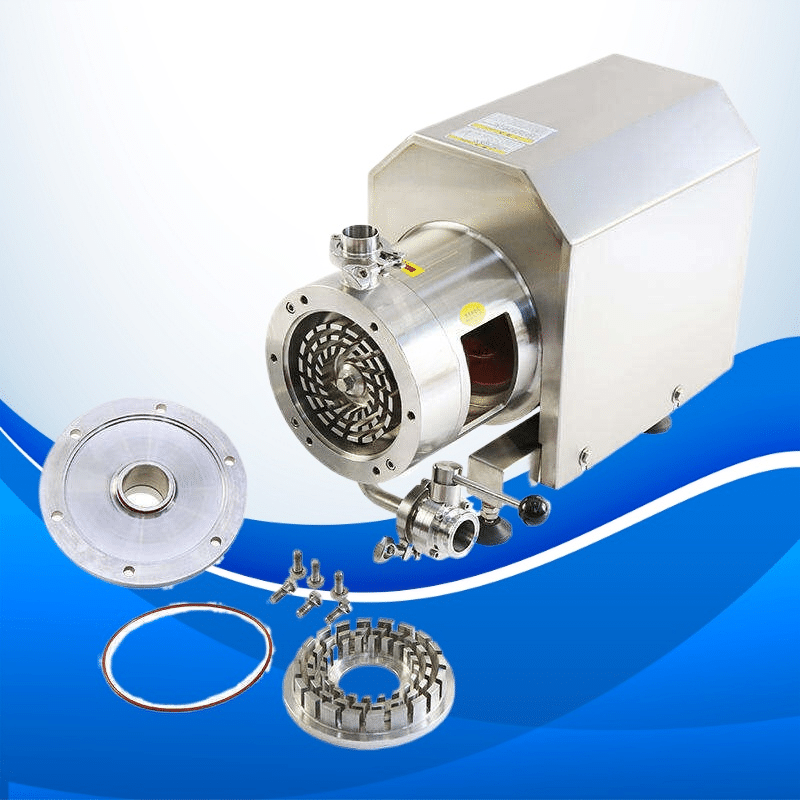

Fast rotor and stator pairs tear through ingredients, shrinking chunks and locking in texture, whether you run a tiny kettle or a nonstop line.

Versatile Customization

- Voltage: 110 V, 220 V, 380 V, 415 V, or even up to 600 V.

- Power: from a compact 1.5 kW on the bench to a full 35 kW in big factories.

- Materials: choose food-grade 316L stainless steel, or save a bit with 304.

Robust & Hygienic Design

- easy-fit sanitary clamps or tri-clamp connections on every inlet and outlet.

- works seamlessly with your existing CIP (clean-in-place) lines to save time.

- smooth internal walls fight buildup and make cleaning a quick wipe instead of a slog.

- sealed mechanical, or cartridge seals keep bearings shielded from grime and splash.

Operational Flexibility

- modular layout lets a technician change a bearing in five minutes, no special tools drawn out.

- can stay put on a factory line or go into a cart for pop-up batches at different stalls.

- runs in discrete batches or keeps pouring steady in a continuous mid-line setup.

📊 Technical Specifications

| Feature | Options |

|---|---|

| Voltage | 110 V → 600 V (customizable) |

| Power | 1.5 kW → 35 kW |

| Rotor Speed | Up to 9,000 rpm (model-dependent) |

| Materials | 316L / 304 Stainless Steel |

| Capacity | From lab-scale to industrial flow rates |

| Connections | Sanitary tri-clamp, flanged, custom fittings |

📍 Typical Use Cases

Cosmetics

Whip a new moisturizer ultra-smooth in the lab, then match that feel when moving to the production floor.

Food & Beverage

Blend vinaigrettes or fruit-infused dairy drinks so every bottle has the same flavor from first pour to last.

Pharmaceuticals

Make suspensions where every particle is the same size, ensuring every dose hits the same mark.

Chemicals

Mix pigments or specialty glues so nothing settles at the bottom, cutting waste and rework on each batch.

✅ Why Pick Our High-Shear Pump?

- Grow at Your Own Pace: Begin with a 1.5-kW unit for lab work or small runs, then boost power to 35 kW when you move to full production.

- Voltage That Fits: We can set the pump to any line voltage from 110 V all the way up to 600 V, so it matches your facility.

- Top-Quality Materials: Use food-grade 316L stainless steel for sensitive batches, or 304 SS when the product isn’t under tight rules.

- Clean and Safe: The sanitary build cuts contamination risks and makes routine maintenance a breeze.

- Tough and Trustworthy: Built for nonstop use, the pump offers high uptime and needs only a little care.

💡 Common Questions

Q1: What voltage should I choose?

If you’re testing on a bench, go with 110 V or 220 V. In factories, you’ll usually find 380 V or 415 V. We also offer a special 600 V model for unique setups.

Q2: Can I upgrade from 304 to 316L later?

Absolutely. Because the pump is modular, changing parts to swap 304 for 316L stainless steel is easy and not very costly.

Q3: Is the pump easy to clean?

For sure. The smooth, sanitary inside plus a CIP-ready seal lets you clean it fast and well—no need to take anything apart unless you want to.

Q4: Can this pump run non-stop?

Definitely. With a power range from 1.5 to 35 kW, plus long-lasting seals, it handles round-the-clock plant conditions and needs very little service.

Want to step up your production line?

Keep taste and performance steady. Whether you are increasing volume, trying a new blend, or fine-tuning speeds, our high-shear pump comes through.

- Pick your voltage (110 to 600 V), motor size (1.5 to 35 kW), and stainless-steel grade (316L or 304).

- Order now and we will set it up to match your flow.

- Talk to our engineers for special designs or spec sheets.