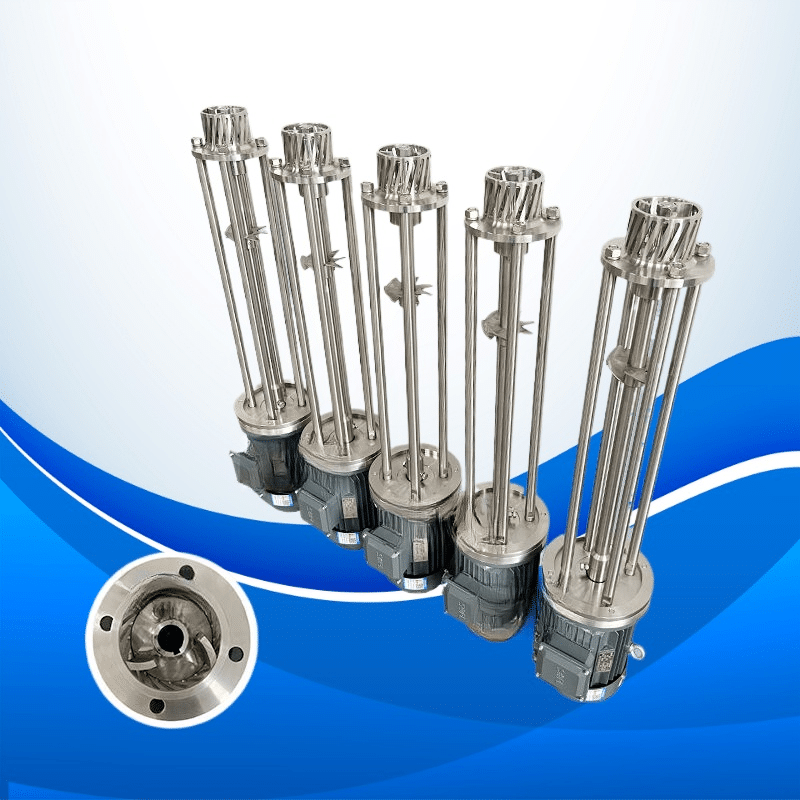

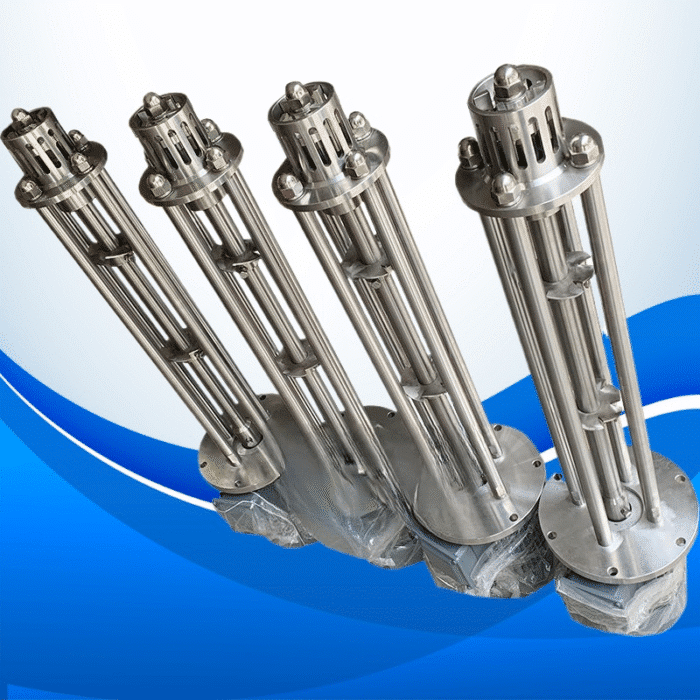

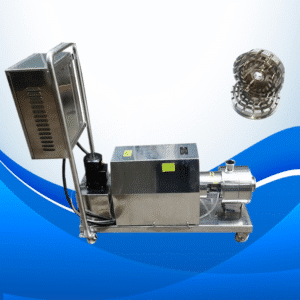

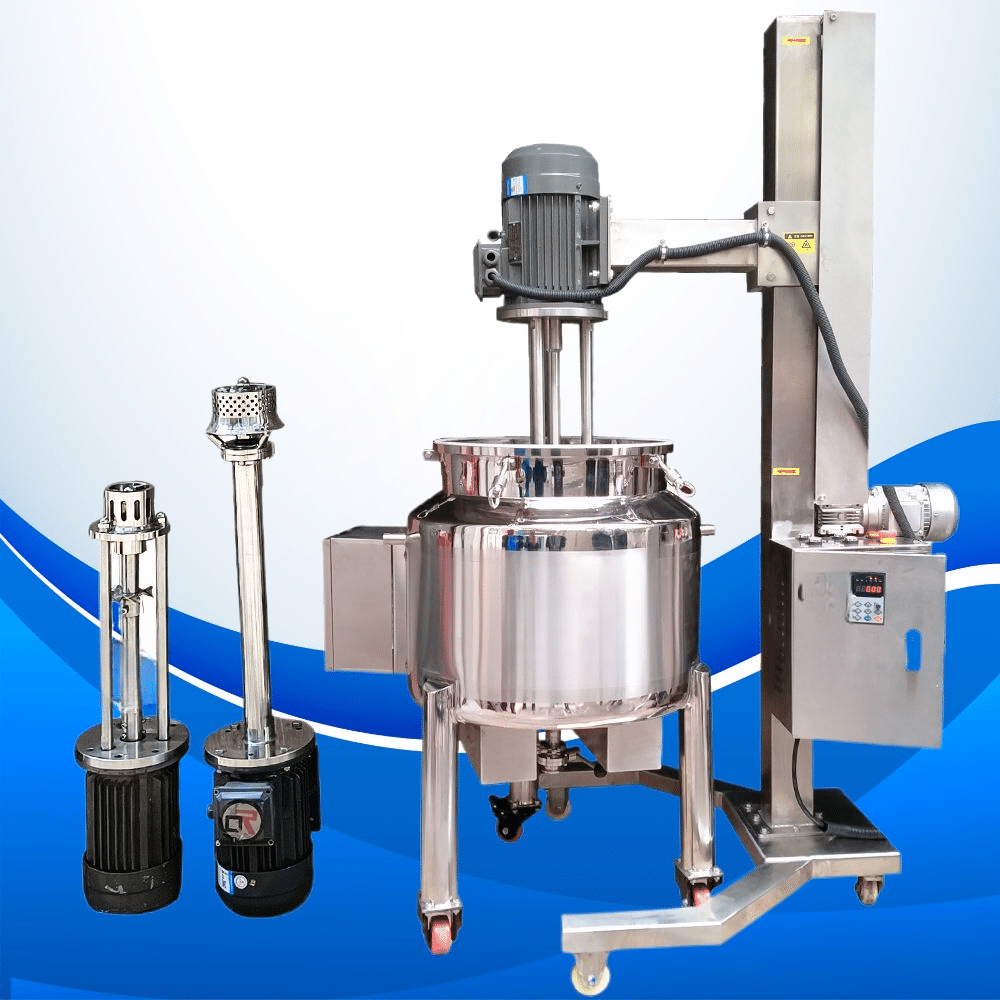

High Shear Mixer for Industrial & Lab

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$780.00

Guaranteed Safe Checkout

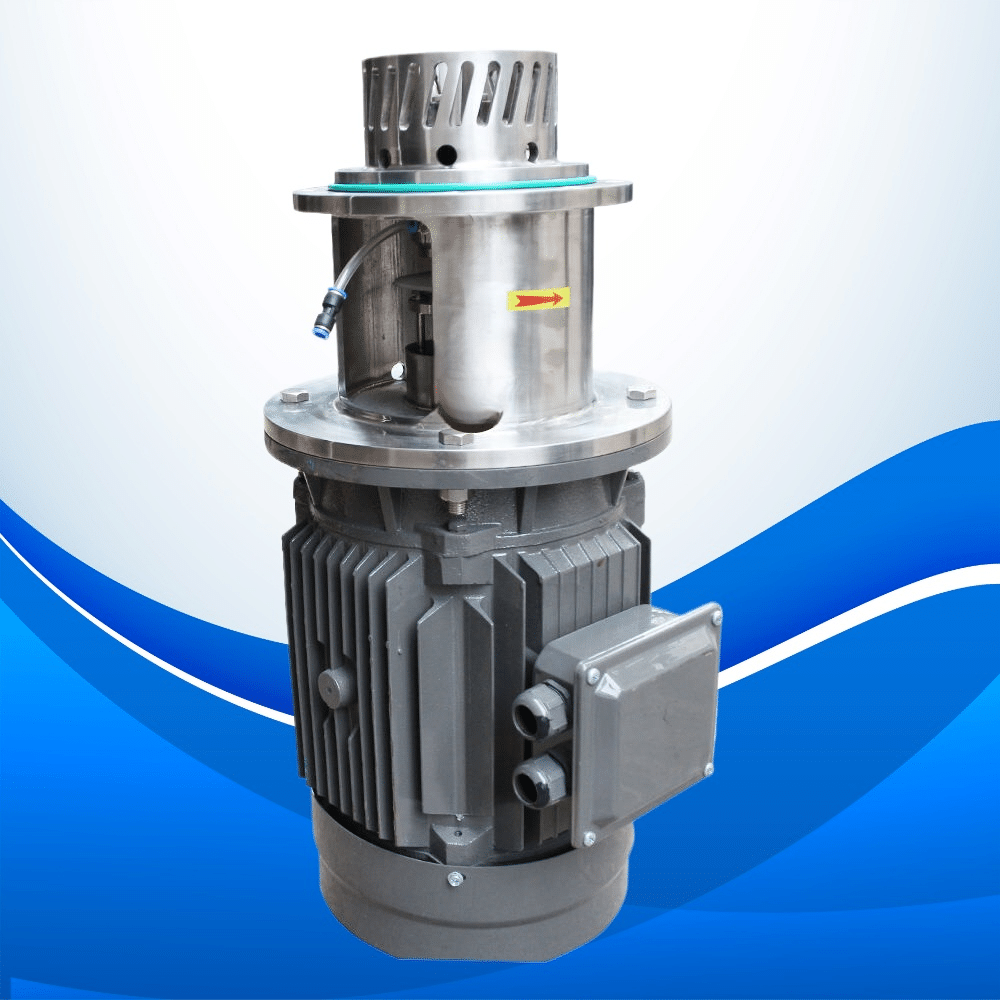

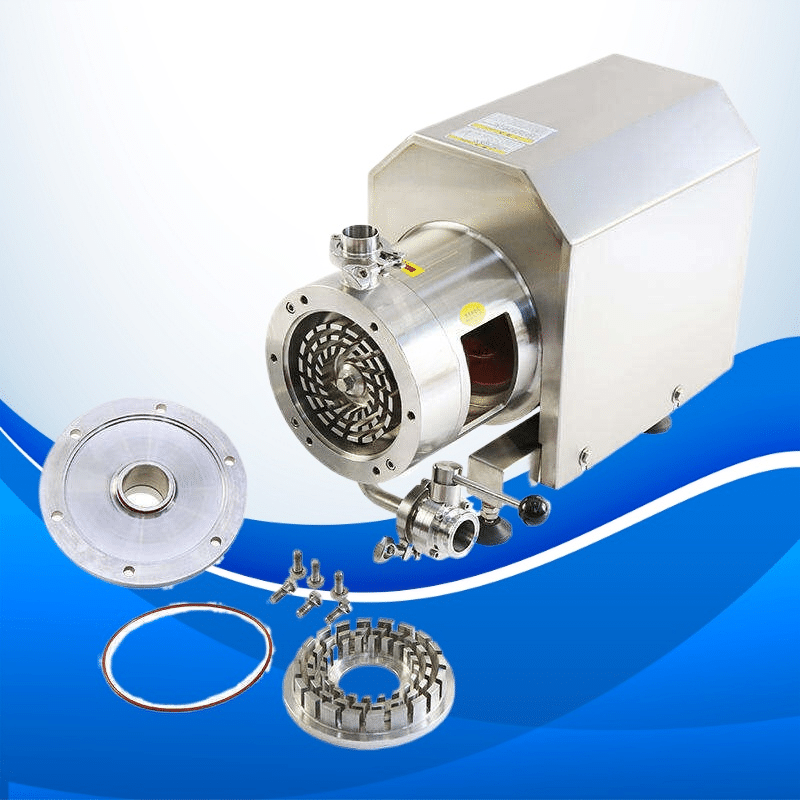

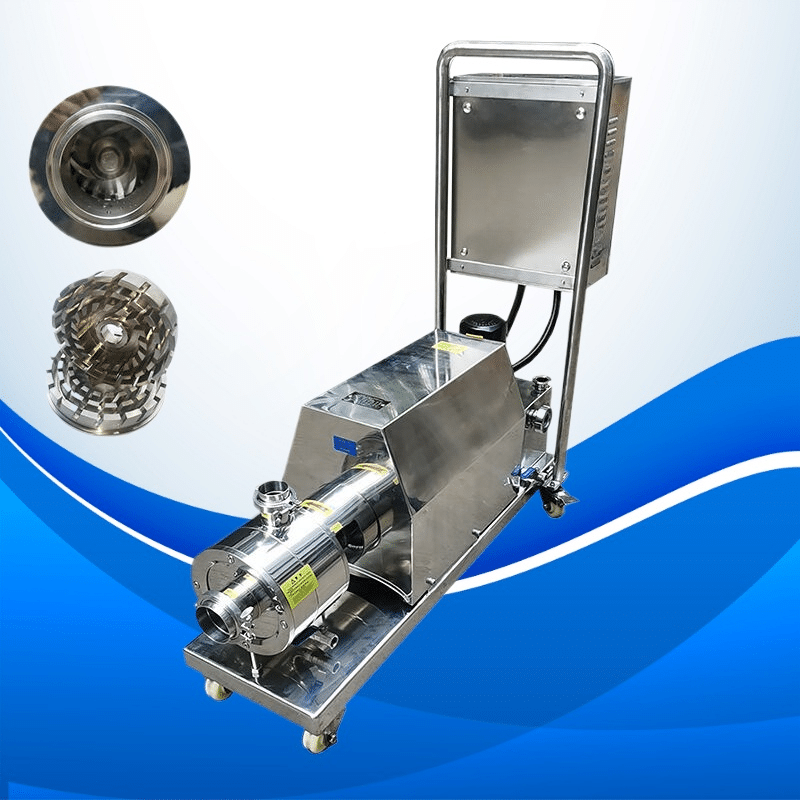

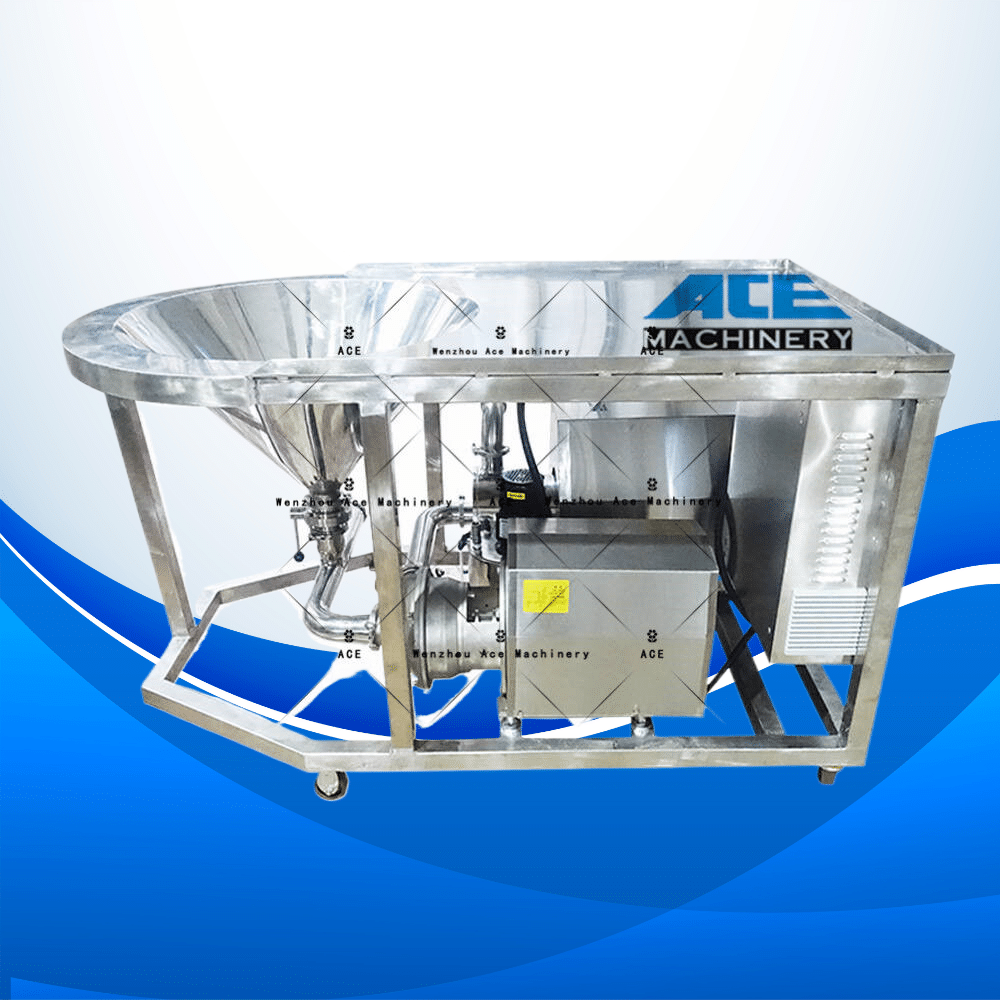

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

Easy to move and lift

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

Take your mixing to the next level with our high-shear mixer, built for precision and real-world power. Whether you are making medicine, creams, food products, paint, or glue, this machine helps you get smooth emulsions, tiny particles, and uniform batches with far less elbow grease.

Key Advantages

High-performance mixing

Bit sizes fall into the sub-micron range, making it perfect for lotions, suspensions, inks, and adhesives.

Adjustable configurations

Select your voltage from 110 V to 600 V and power from 1.5 kW to 35 kW so it fits your line perfectly.

Premium materials

Pick 316L or 304 stainless steel to meet every hygiene, corrosion, and clean-in-place (CIP) rule.

Energy-efficient and safe

Sealed bearings, high torque, and rugged build keep your plant running and cut maintenance visits.

Quick customization

Modular design lets you choose rotor-stator sizes, tank adaptors, and extras made just for your process.

Real-World Applications & Scenarios

Cosmetics and Personal Care

Make velvety lotions and serums by finely blending oil and water, with no heat damage to actives.

Food and Beverage

Mix sauces, dressings, and plant milks to steady dispersion, giving consumers shelf-ready, consistent quality.

Chemical Coatings and Paints

Equal pigment and filler spread cuts clumps, so color, thickness, and performance stay uniform from first drop to last.

Pharmaceuticals & Nutraceutical

Make reliable injectable and drinkable solutions with the right particle size in clean, stainless 316L workspaces.

Adhesives & Sealants

Blend resins and hardeners to the exact thickness every factory needs for strong, lasting joints and packages.

Technical Specifications

- Voltage: 110 V / 220 V / 380 V / 480 V / 600 V – Works on power grids everywhere

- Power: 1.5–35 kW – Fits small labs or full production halls

- Material: 304 SS / 316L SS – Resists corrosion, passes food and pharma tests

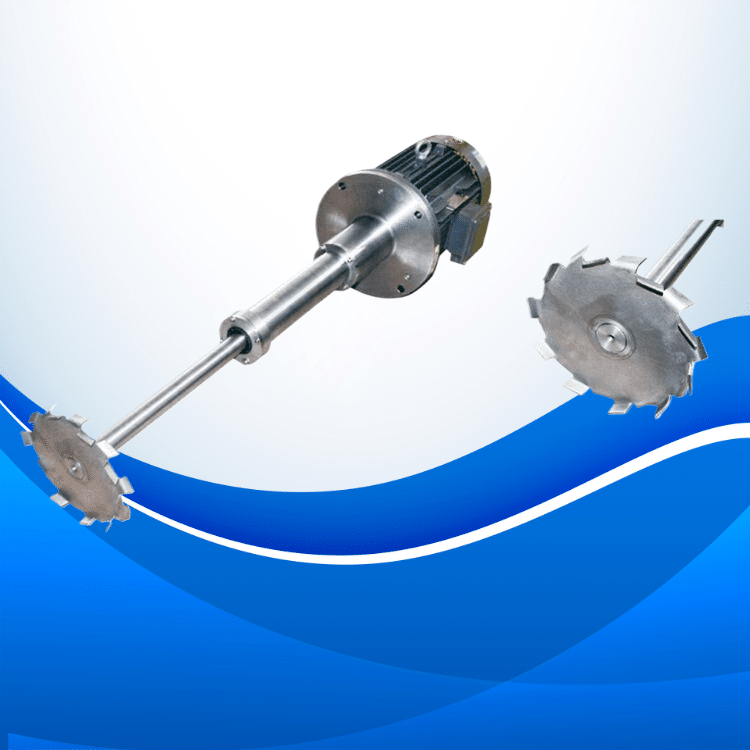

- Rotor–Stator: Grab a rotor-stator set in the size you need – Boosts sheer speed and output

- Sealing: Mechanical, lip, magnetic – Stops leaks, keeps the mix clean

- Control: Manual or PLC plug-in – Run speed, time, and ramp exactly how you want

Why Choose Our High Shear Mixer?

- Wide voltage and power choices fit both bench tops and big lines.

- Its high-shear action breaks lumps fast, even in thick fluids, for a smooth finish.

- 316L s.s. housings last a long time, clean up easy, and pass every audit.

- Each unit is built to match your recipe volume, line speed, and layout.

- Our pros handle install, training, and quick service so you stay up and busy.

✅ Ready to Customize & Order?

Talk to us now to pick voltage, power, material, and extras. Step up your mix quality, save resources, and trim waist.

👉 Ready to get started?

Just ask for a quote or a design chat, and our engineers will work with you one-on-one.

❓ Frequently Asked Questions

Q: How do I pick the right voltage and power?

A: For small tests, units between 110-220 V and 1.5-5 kW work great. If you’re moving to pilot or full production, 380-600 V and 10–35 kW give steadier performance.

Q: What’s the difference between 304 and 316L?

A: 316L shrugs off corrosion better, so it shines in pharma, dairy, or salty ocean air. 304 suits most regular food and chemical jobs.

Q: Will it fit my current setup?

A: Absolutely. The mixer can bolt on, roll around, link to CIP lines, and hook up to any PLC.

Q: What kind of upkeep does it need?

A: Just clean it, check the seals, and take a quick look at the rotor-stator. With so little work, you keep almost all your uptime.