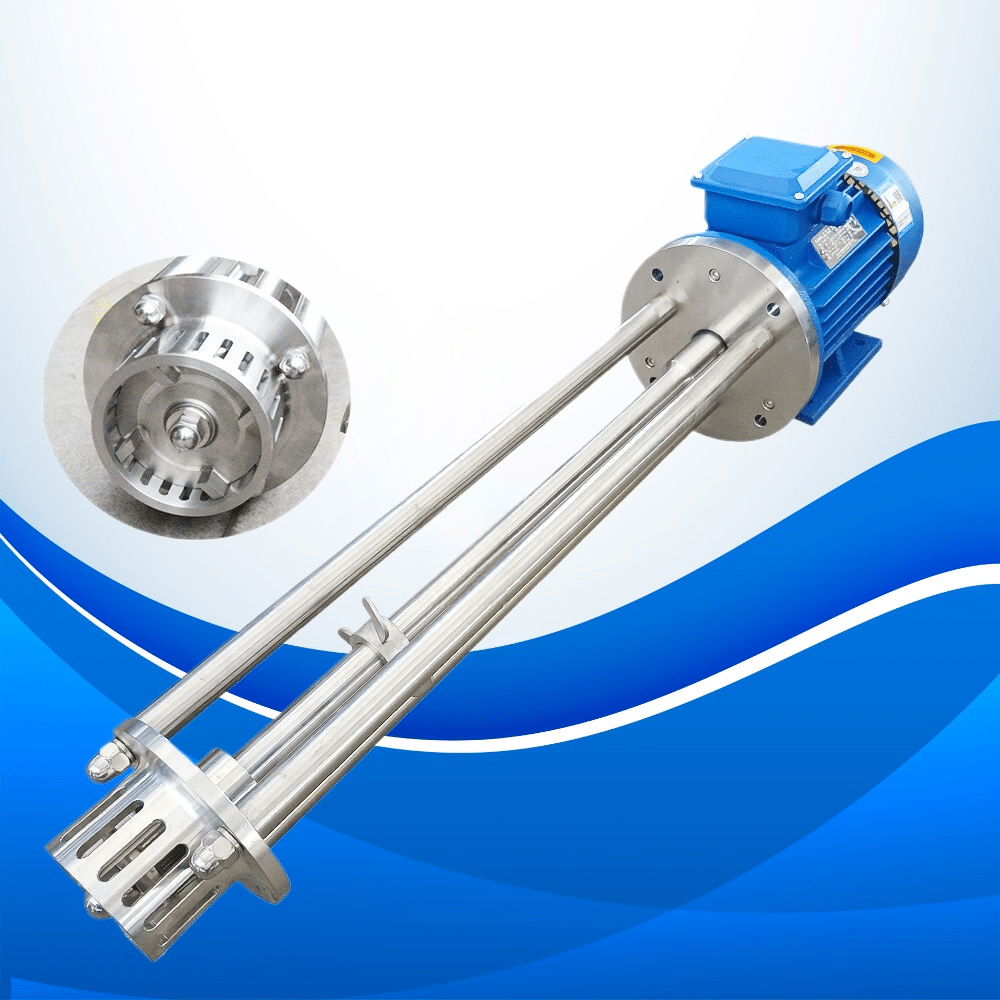

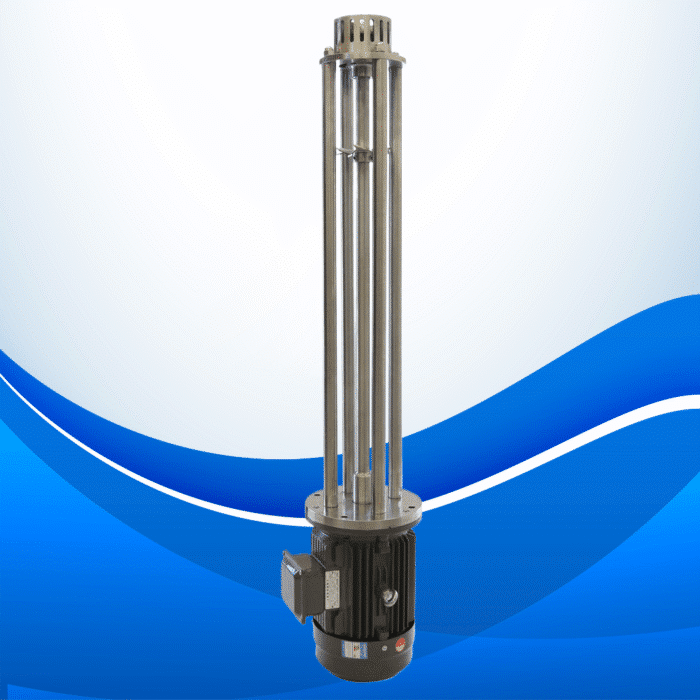

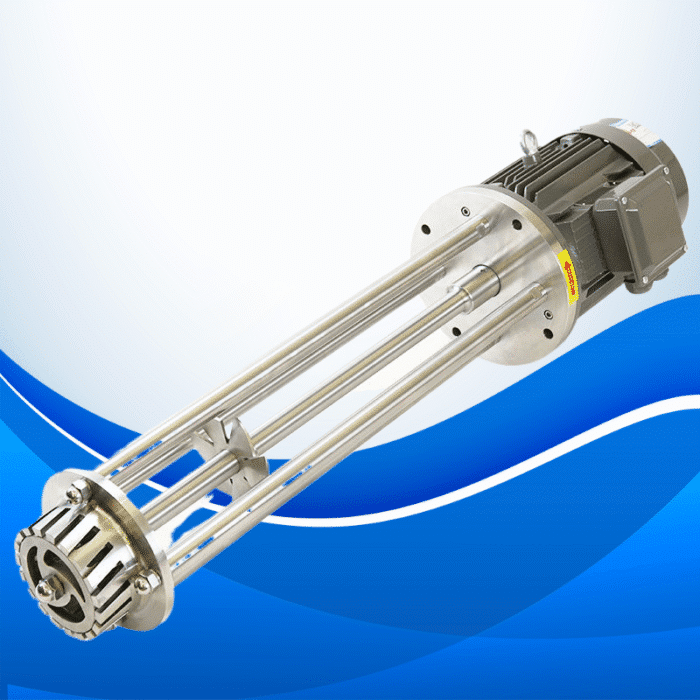

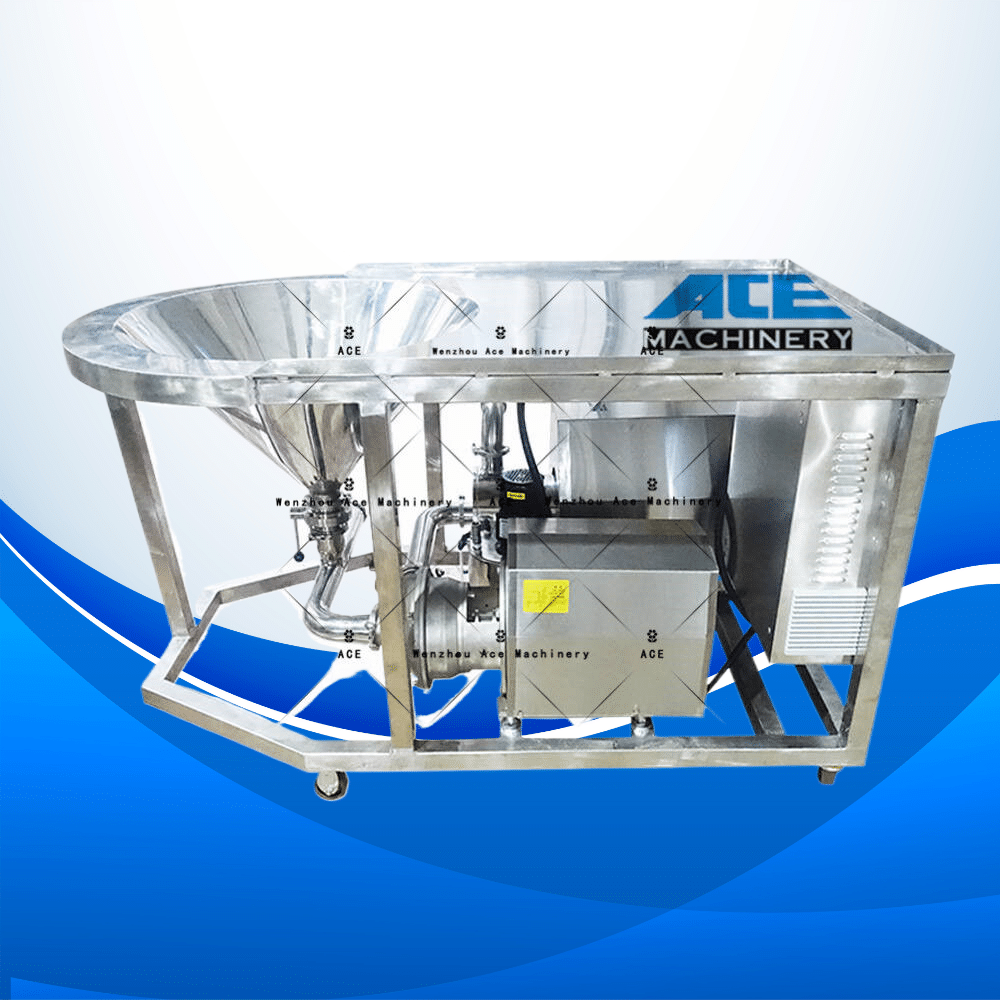

High Shear Homogenizing Mixer

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$880.00

Guaranteed Safe Checkout

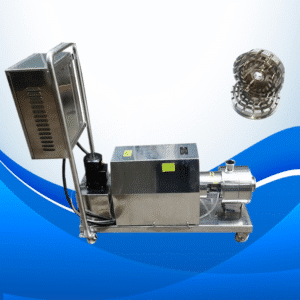

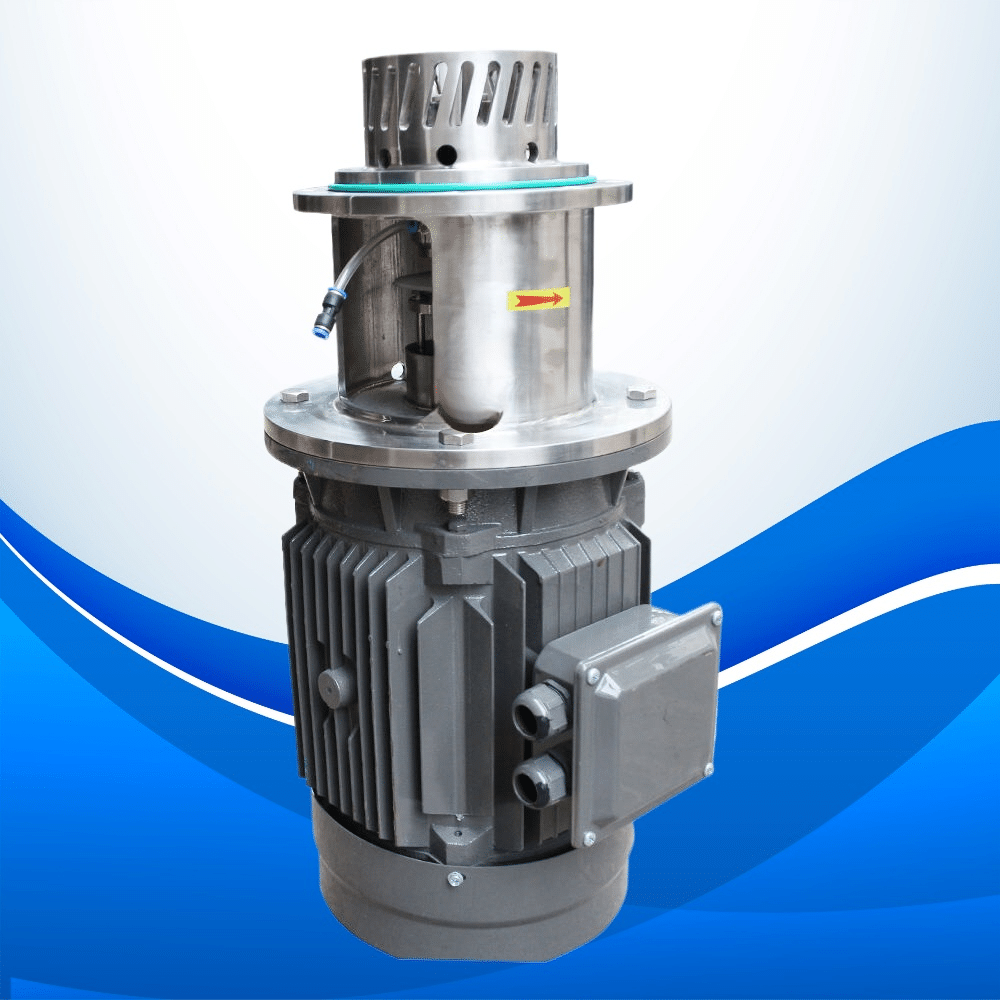

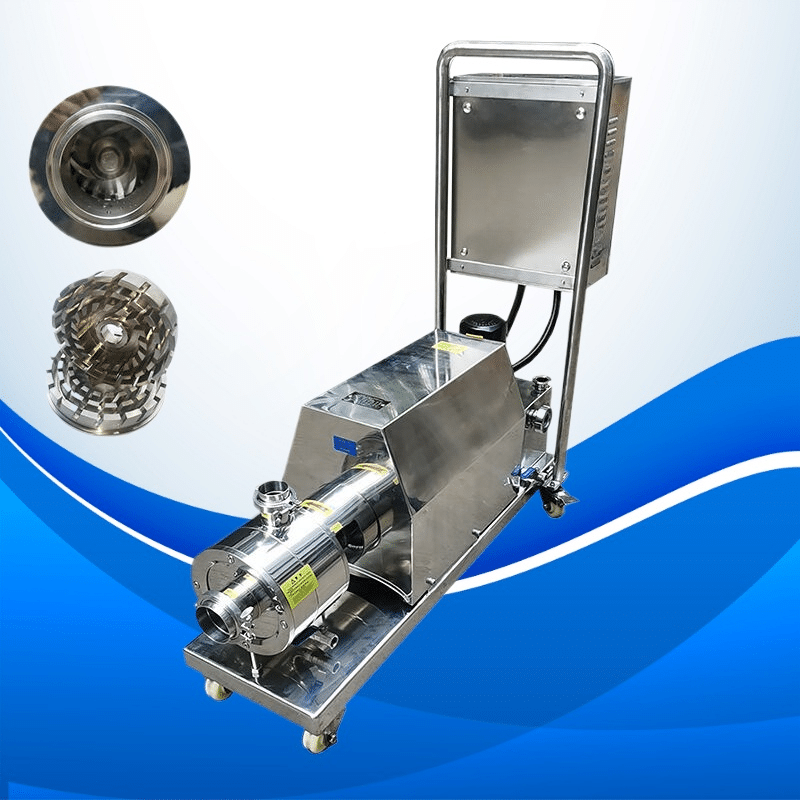

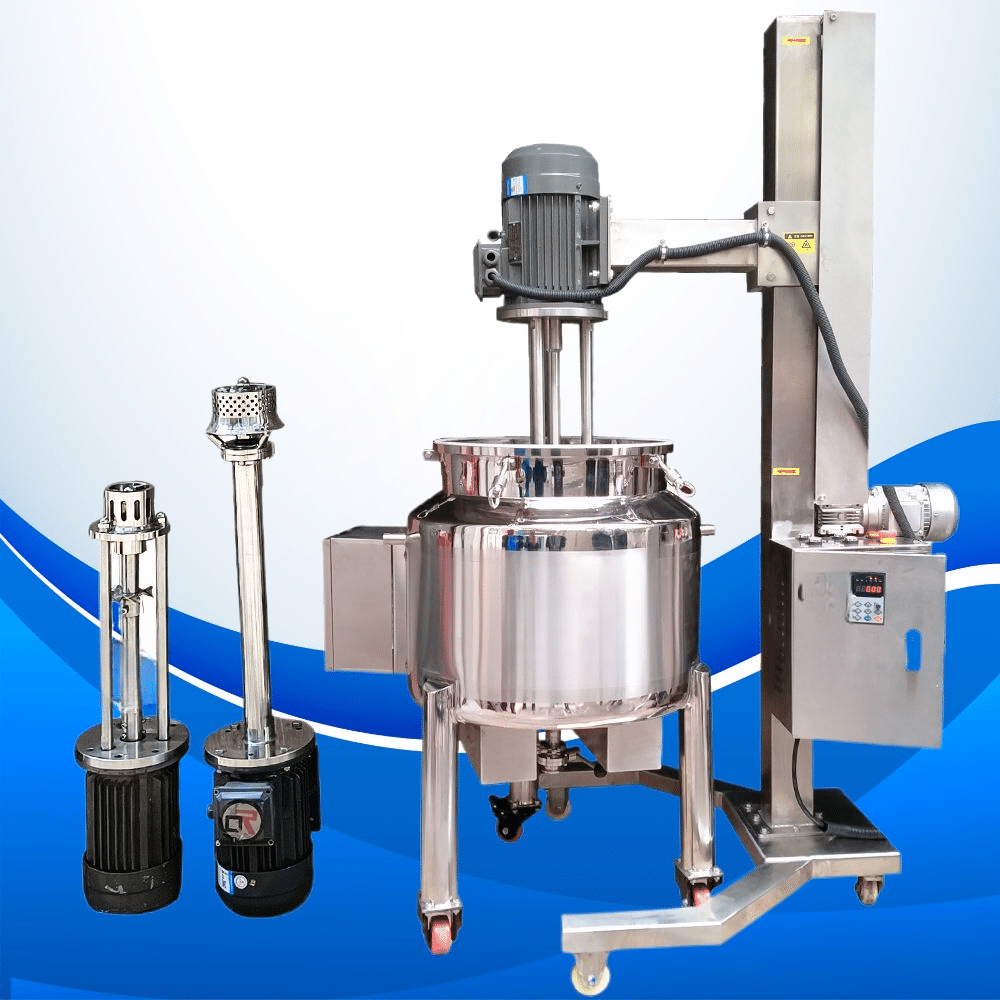

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

Easy to move and lift

Features heating, cooling, vacuum, and other functions

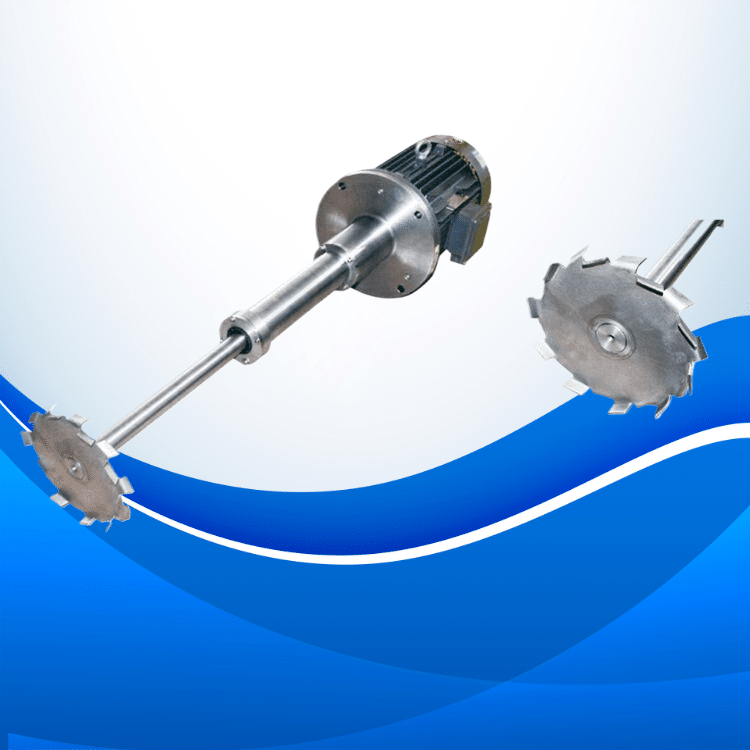

Recommended RPM: 1480/2850 RPM

High Shear Homogenizing Mixer: Boost Your Production Line with Reliable, High-Quality Blends.

When plants rely on spotless mixes, smooth emulsions, or stable dispersions, the High Shear Homogenizing Mixer has earned its place on the floor. Food makers, drug formulators, skin-care brands, and chemical houses all trust this gear because it combines speed with repeatable top performance.

Key Benefits of High Shear Homogenizing Mixers

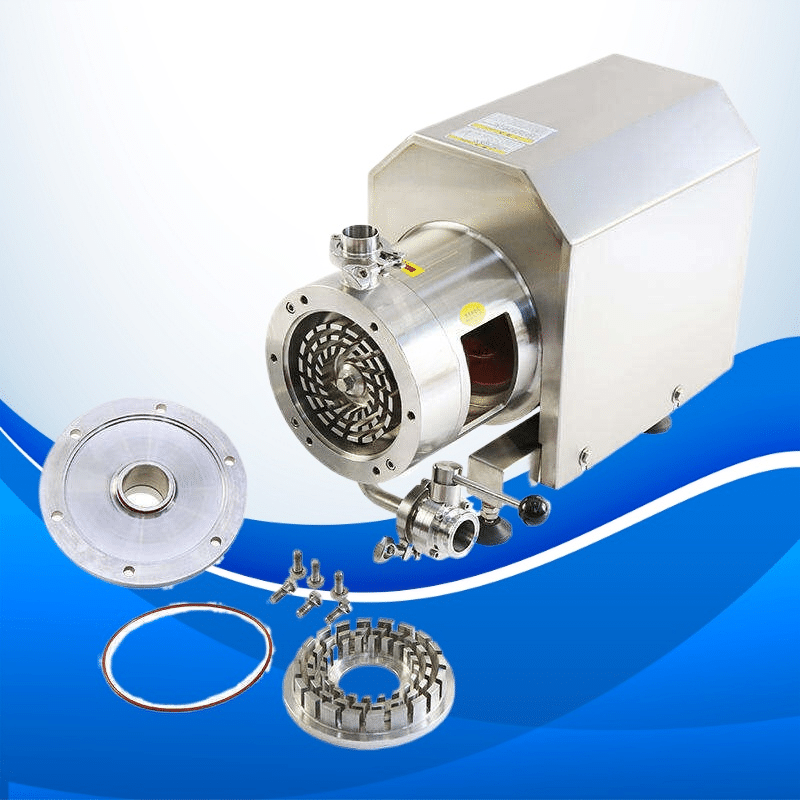

Designed for serious shearing, the mixer harnesses strong motor power and precision blade geometry to tear through material at high speeds. The result is a clean break-up that leaves no lumps and no separation down the line. Take a glance at the highlight benefits:

- Superior Mixing Performance: Uniform size reduction means longer shelf life and less post-process adjustment.

- Increased Efficiency: Move big batches in short cycles and cut waiting time without losing the quality that passes inspections.

- Customizable Power and Voltage: Select anywhere from 1.5 kW up to 35 kW, and match 110 V to 600 V supply so the machine slots straight into your set-up.

- Material Options to Match Your Needs: Choose either 316L or 304 stainless steel, so you can get the right amount of corrosion protection based on the chemicals you handle.

- Built to Last: Every component is made for serious use, so you get a long-running machine and face very little downtime.

Applications and Real-World Use Cases

The high-shear homogenizing mixer crosses industries and tackles many jobs. Check out a few ways it could reshape your line:

Food and Beverage Industry:

- Emulsions & Sauces: Whips up silky, stable blends for mayonnaise, dressings, and other sauces.

- Dairy Processing: Keeps milk, cream, and yogurt evenly mixed, stops separation, and boosts creaminess.

- Juice and Smoothie Production: Blends fruit pulp evenly, so every bottle has the same mouthfeel.

Pharmaceutical and Cosmetics Industry:

- Creams & Lotions: Mixes active ingredients and emulsifiers well, making lotions, serums, and creams people trust.

- Suspensions & Formulations: Homogenizes drug mixes, improving absorption and keeping each dose the same.

Chemical Processing:

- Pigment Dispersion: Breaks up thick pastes, spreading pigments evenly in paints and coatings.

- Polymer Processing: Combines polymers and extras consistently, helping make strong adhesives, sealants, and films.

Energy and Environmental Applications:

- Biomass Processing: Helps keep organic feedstock blended evenly, so biofuel production runs smoothly.

- Water Treatment: Assists in mixing chemical additives that keep drinking water clean and safe.

Customization Options for Specific Needs

For big plants, “one-size-fits-all” never works. Our high-shear mixers can be tailored to fit your exact operation.

- Voltage Range: Pick from 110V, 220V, 380V, 480V, or even 600V, making setup easy no matter where you are.

- Power Range: Go with 1.5 kW to 35 kW, depending on batch size and thickness. Higher-power units deliver quicker, stronger shear for tough mixes.

- Material Construction: Get 316L stainless for maximum corrosion resistance, or choose 304 if budget matters. That way, the mixer matches the chemicals you’ll handle every day.

Technical Specs:

- Power: 1.5 kW up to 35 kW, depending on the unit.

- Voltage: Set anywhere from 110 V to 600 V, your choice.

- Materials: Pick 304 or tougher 316 L stainless steel.

- RPM: Change the speed easily for precise mixing or emulsifying.

- Flow Rate: Moves 100 to 1,000 liters per hour, based on model.

Why Pick Our High Shear Homogenizer?

- Time Saver: No matter if you work with liquids, pastes, or slurries, our mixer cuts blend time while boosting output.

- Better Quality: Get that ultra-smooth finish emulsion, suspension, or dispersion customers love.

- Long Life: Built from top-grade 316 L steel, the unit laughs off rust and wear for years of trouble-free use.

- Full Control: Choose power, voltage, and material so the machine fits your exact job.

Call Us Today!

Stop settling for slow, inconsistent mixing. Our high shear homogenizer speeds up your line and locks in great quality every batch. Contact us now and well build a mixer that fits your process like a glove.

Still not sure what you need? Give us a call, and we will walk you through the options so you end up with the mixer that fits your work the best. Hunt us down for all the details!

Frequently Asked Questions (FAQs)

Q1: Who usually buys high shear homogenizing mixers?

A1: Food-and-drink makers, drug companies, chemical plants, and cosmetic brands use them to blend emulsions, keep particles suspended, and break up powders.

Q2: How fast can this mixer work?

A2: Flow rates go from 100 to 1000 liters an hour, so you can pick a model that suits a small lab batch or a full industrial run.

Q3: Can I pick a different motor size or voltage?

A3: Absolutely. Motive power runs from 1.5KW to 35KW, and we wire for 110V to 600V, so the machine plugs right into your shop.

Q4: What is the mixer made from?

A4: Standard jobs get 304 stainless, but 316L is available when extra rust-proofing is a must.

Q5: How does the high-shear mixer make mixing faster and better?

A5: Because it spins parts really fast, the high-shear mixer chops big bits down to size and mixes them evenly, letting you make smooth sauces, lotions, or paints way quicker than with older machines.