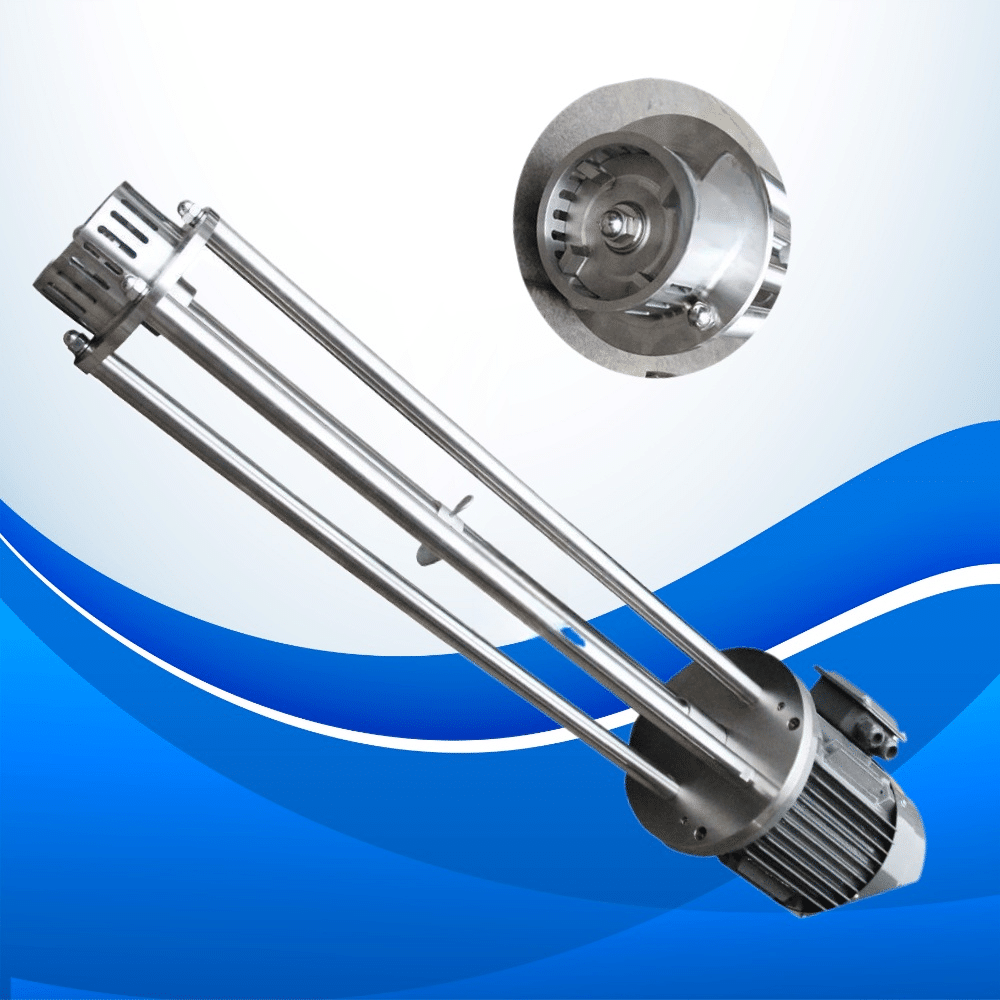

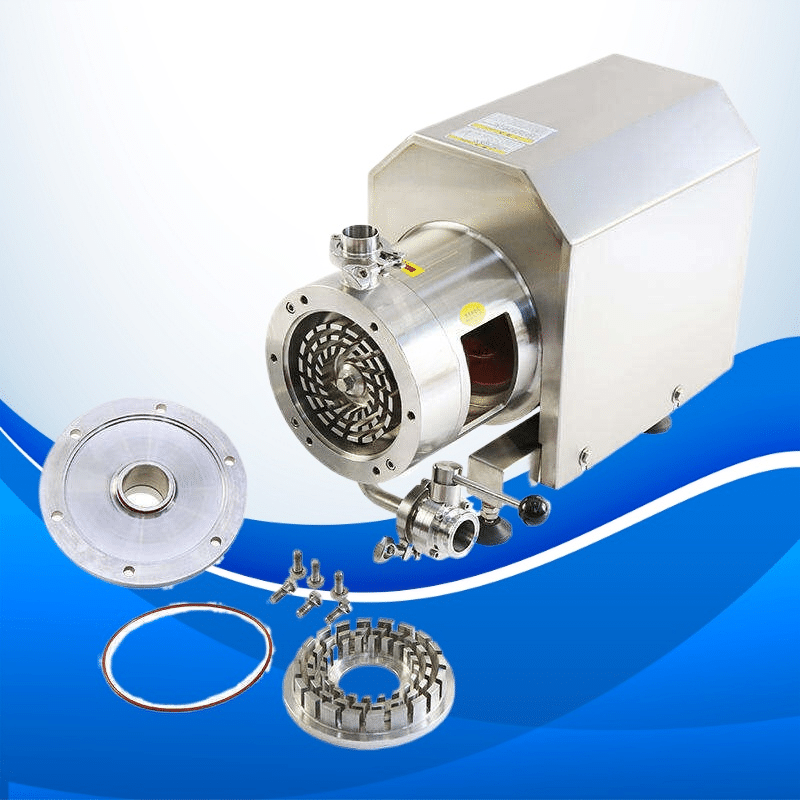

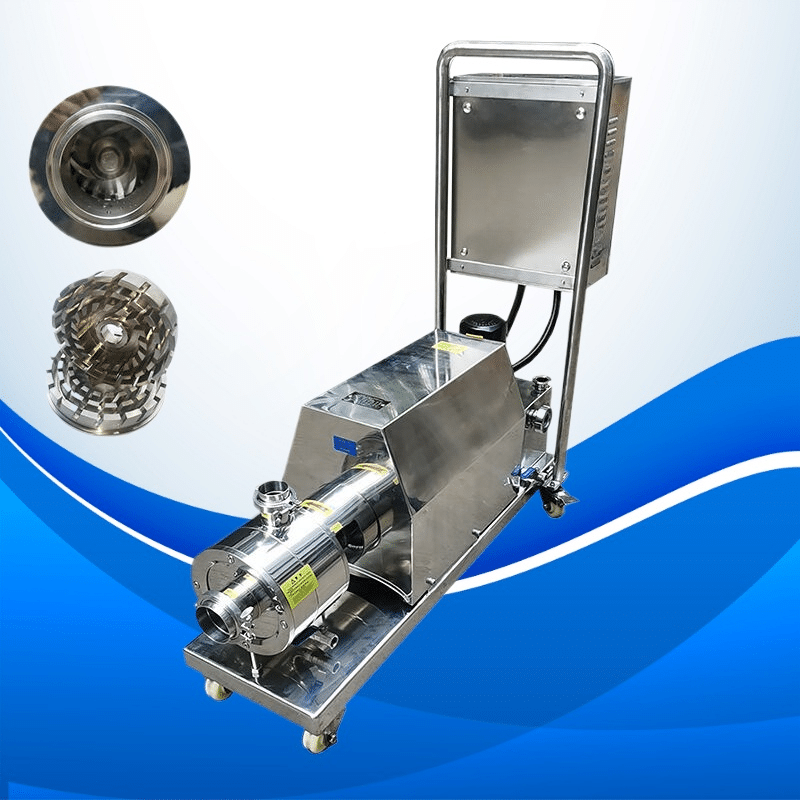

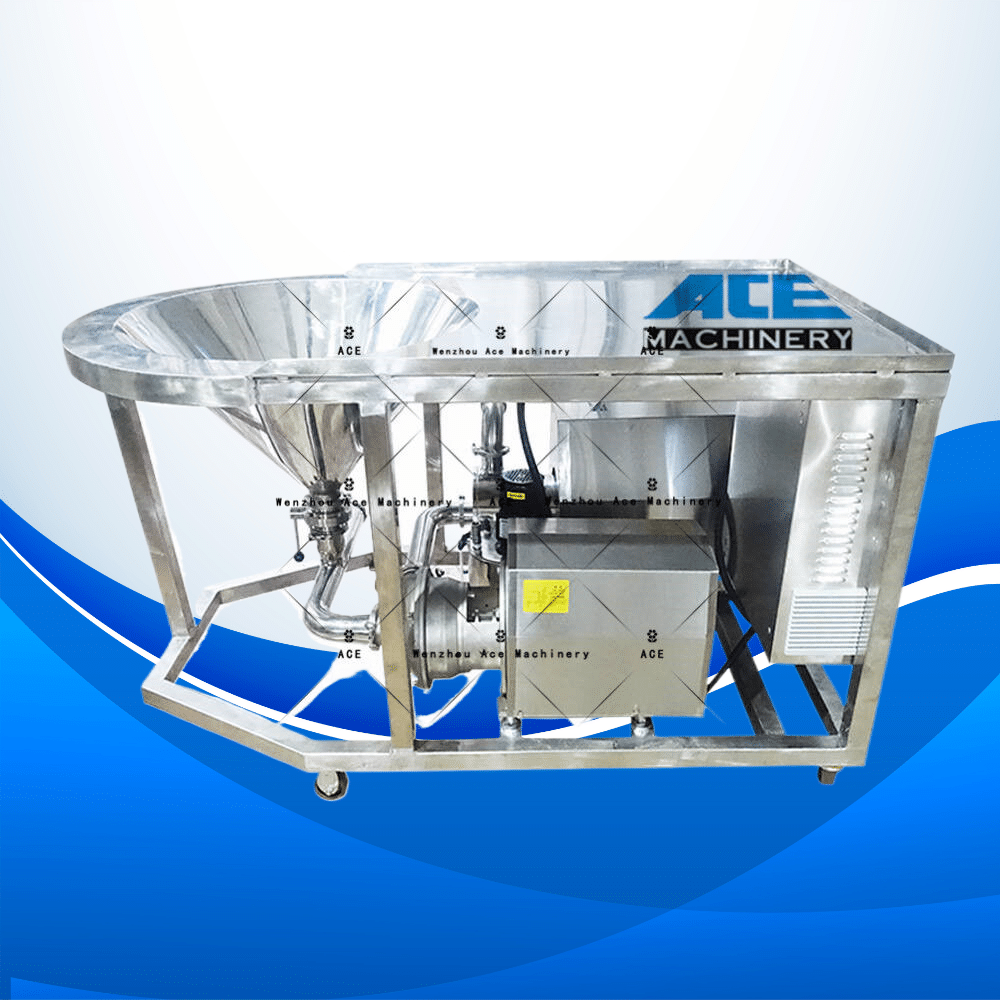

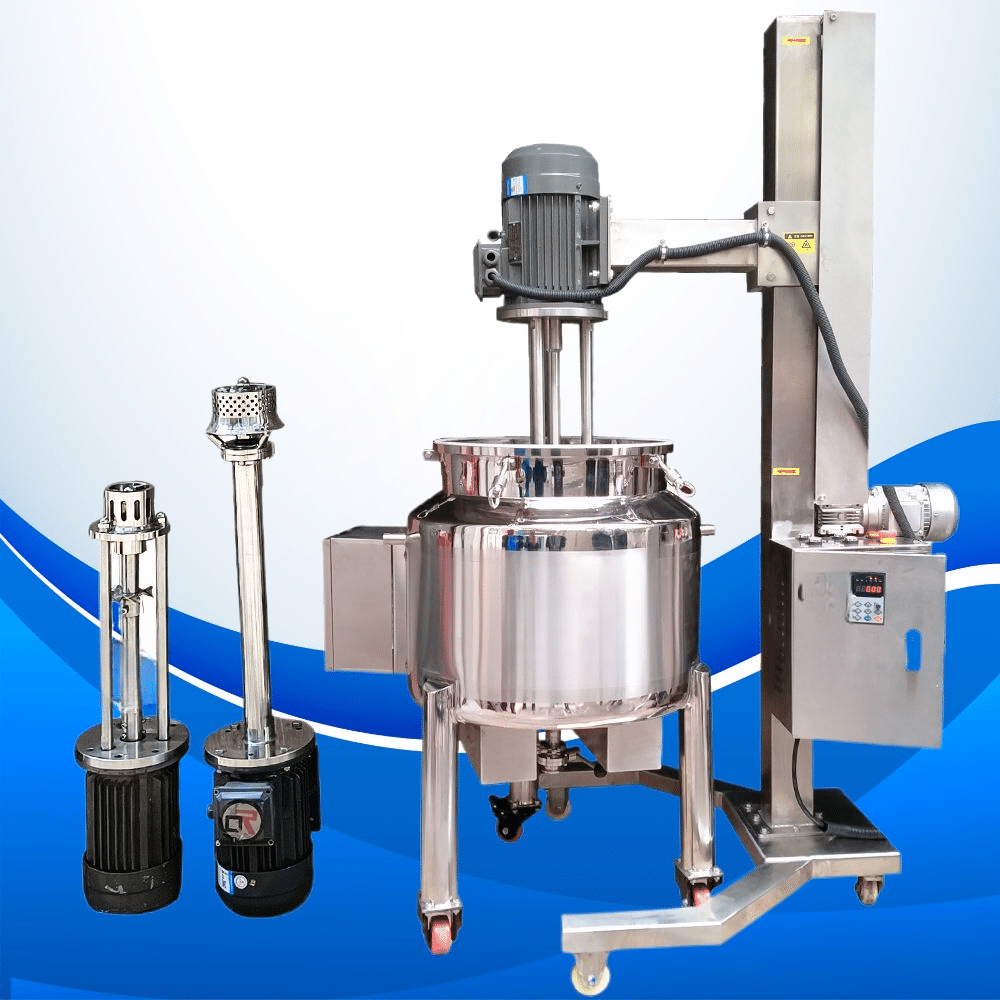

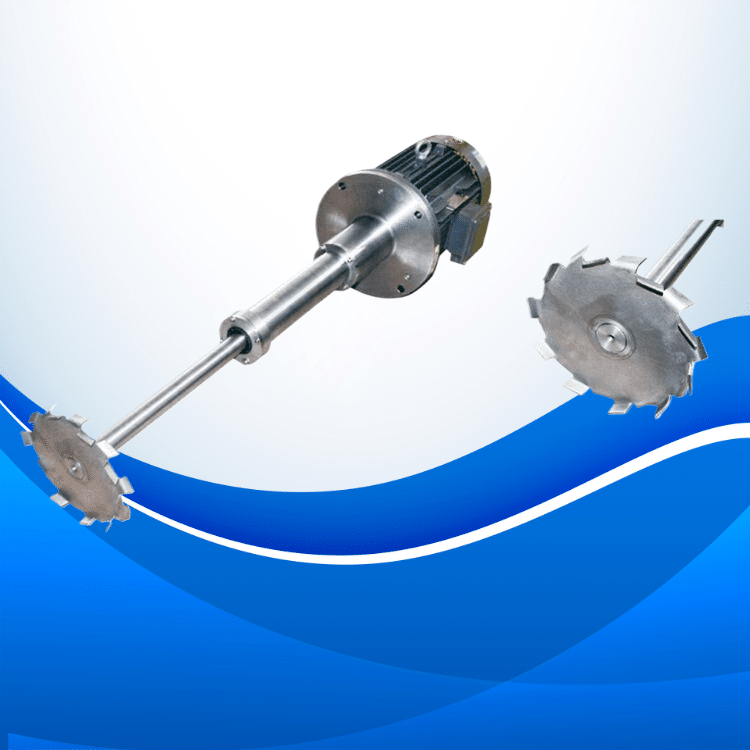

High Shear Homogenizer for Emulsifying, Mixing & Dispersing

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$980.00

Guaranteed Safe Checkout

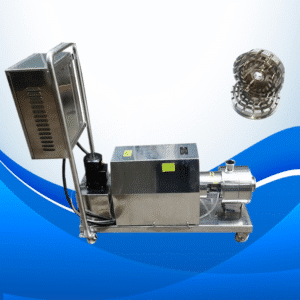

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

Easy to move and lift

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

Product Overview: High Shear Homogenizer

A high shear homogenizer is a must-have tool for anyone making products in pharma, cosmetics, food, chemicals, or biotech. With its superfast blades, it blends, breaks down lumps, and pulls stubborn ingredients together, no matter how thick or sticky the mix is.

🔍 Why Pick Our High Shear Homogenizer?

Our machines are built for the factory floor and still give you the kind of accuracy, cleanliness, and long life you expect from top gear. From thick creams and floating suspensions to glossy sauces and specialty chemicals, this unit keeps texture even, shelf life longer, and process time shorter.

📈 What Can You Make?

- Pharma: Mix active powders, whip ointments, make NATO-dispersions.

- Cosmetics: Blend creams, lotions, gels, serums and oil mixes.

- Food: Stabilize dairy, whisk sauces, fold flavors, keep drinks steady.

- Chems: Improve paints, blend lubricants, coat metals, mix adhesives.

- Biotech/Lab: Break cells, prep samples, pull out proteins, check DNA.

Think of a super-smooth lotion or a never-separating sauce; our homogenizer helps you nail that finish batch after batch.

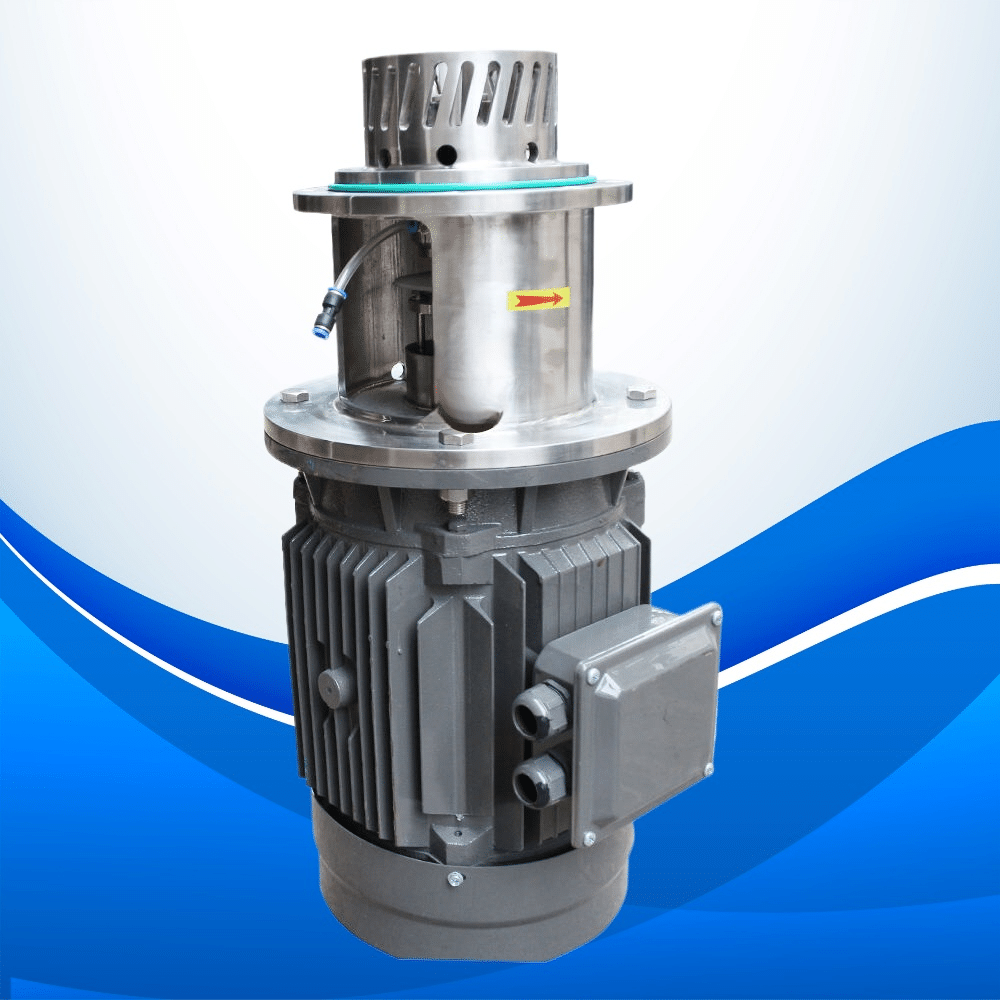

⚙️ TECH SPECS

- Voltage Choices: 110V, 220V, 380V, 415V, or even up to 600V.

- Power Rating: 1.5 kW to 35 kW per unit.

- Body Material:

- 304 stainless steel – budget-friendly and resists rust.

- 316L stainless steel – best choice for pharma and biotech cleanup.

- Control System: Simple manual knobs or modern PLC touch screen.

- Speed Range: Adjustable all the way to 3000 RPM.

- Seal Design: Double mechanical seal keeps liquids in.

- Mounting Style: Inline, batch, or skid versions available.

🧪 ON-THE-FLOOR BENEFITS

Put a high-shear homogenizer into your line and watch formulation time drop by half. You’ll eliminate swirl marks, ditch inconsistent batches, and free staff from endless manual blending. Just program it, walk away, and know every mix meets GMP and ISO.

💡 TAILORED SOLUTIONS

No two plants run the same setup. That’s why we give you:

- Voltage set to local code.

- Power tweaked for batch size and thickness.

- Material matched to clean room grade.

Need a special pipe layout or stronger torque? Our engineers will sketch, quote, and build the fix you need.

🛒 TIME TO ORDER

Get a high-shear homogenizer that delivers every batch, every time. Click below for a quick quote, or call our team to chat about your custom features.

🔧 Reach out today for a custom plan that speeds up your product development.

❓ Frequently Asked Questions (FAQ)

Q1: Can I use this with both water- and oil-based products?

Yep, it works great whether your mix is water-in-oil or oil-in-water.

Q2: Is it CIP-and-SIP-friendly?

Sure thing-clean-in-place and sterilize-in-place versions are on the table.

Q3: How do I pick between 304 and 316L stainless steel?

Choose 304 for everyday jobs, 316L for pharma, biotech, or really harsh stuff.

Q4: Can I run it on a continuous production line?

Definitely-inline models slide right into nonstop setups without a hitch.