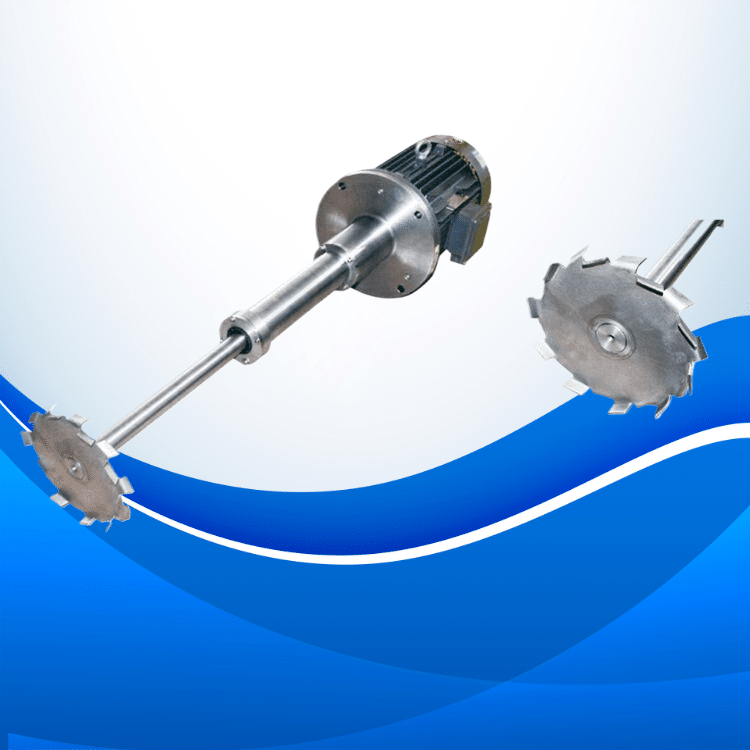

High Shear Blender for Industrial Mixing

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$2,100.00

Guaranteed Safe Checkout

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

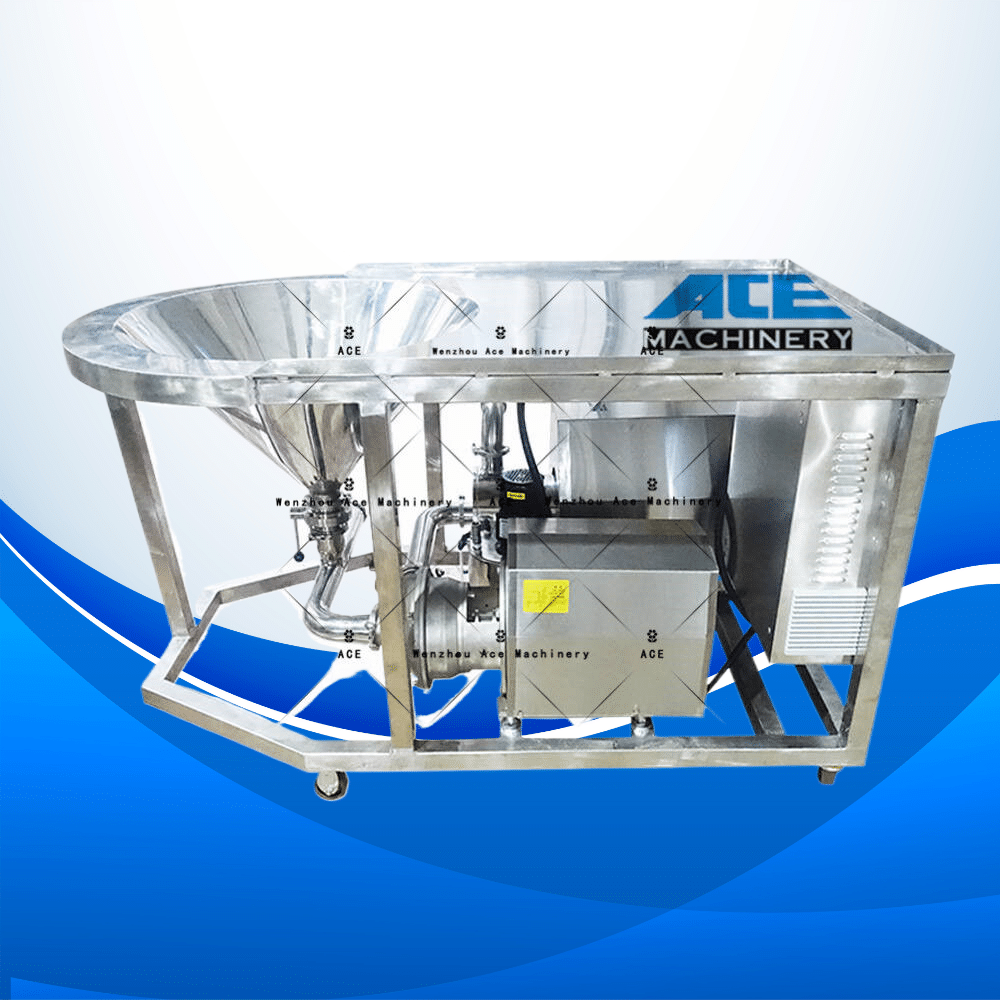

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

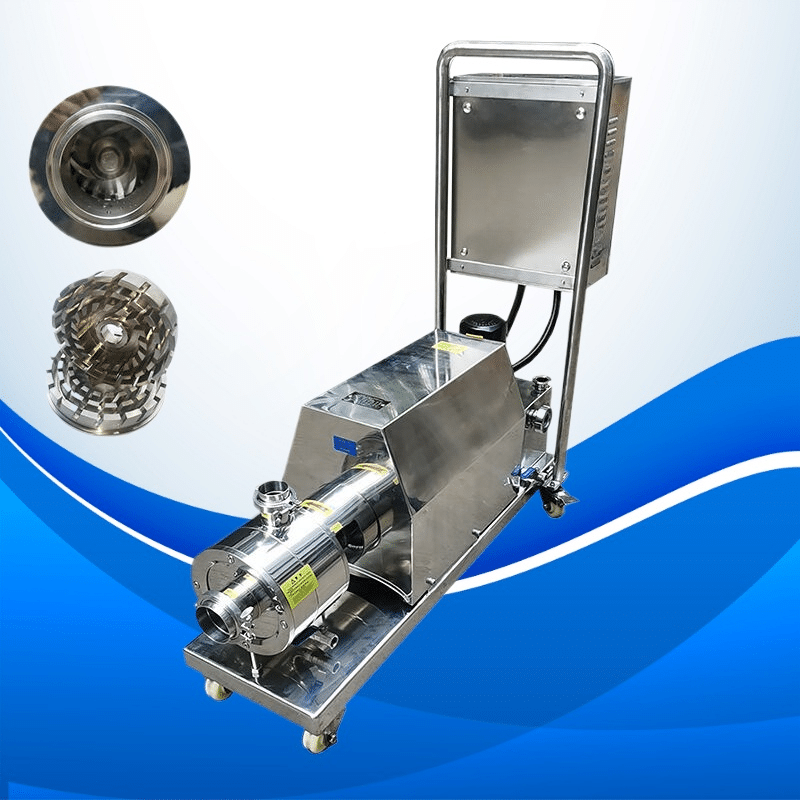

Easy to move and lift

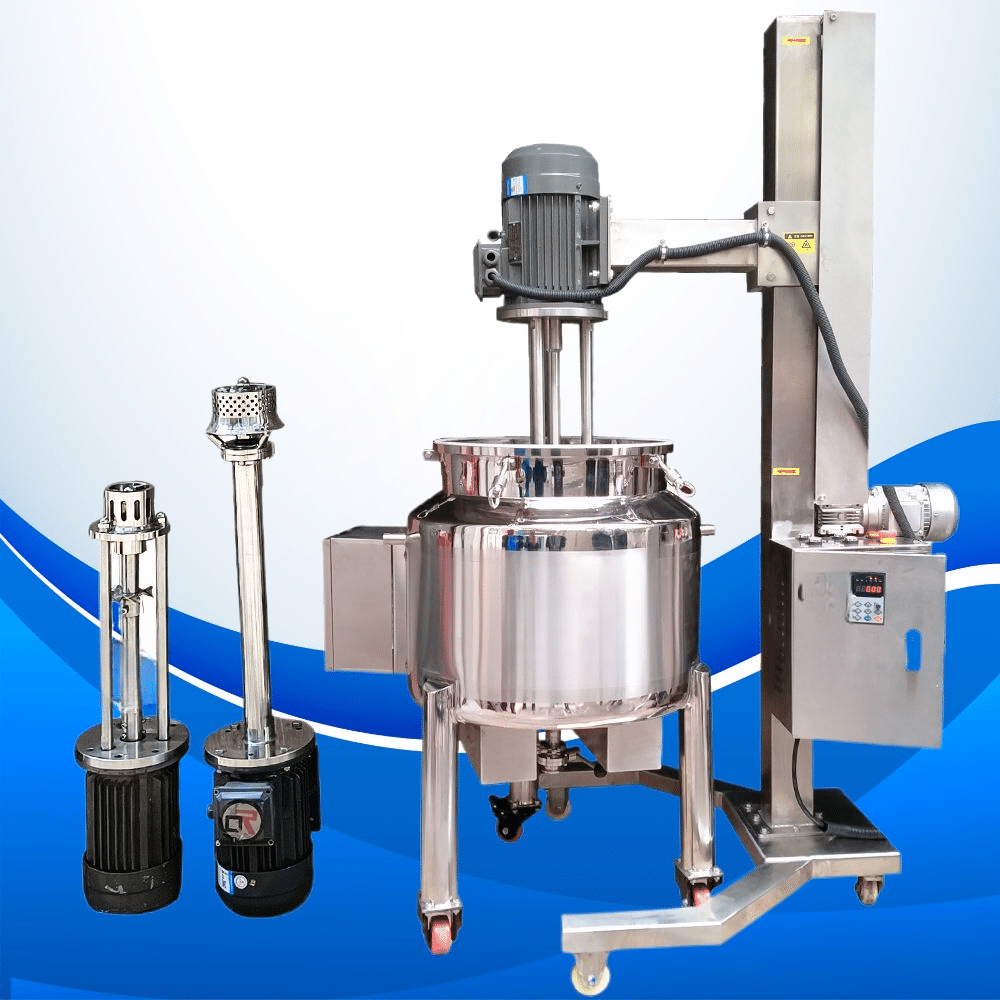

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

High-Shear Blender: Fast, Consistent Mixing When It Matters Most.

When every batch needs to look, feel, and act the same-and it must happen quickly-a high-shear blender steps in. Built for factories that can’t afford variation, these machines chop, fold, and homogenize at speeds that leave standard agitators behind. From pills and lotions to dressings and specialty chemicals, high-shear units set a new pace for large-scale mixing.

What is a High-Shear Blender?

A high-shear blender is a heavy-duty mixer with lightning-fast rotors and tight stationary blades that force materials past each other over and over. This ruthless shear breaks up lumps, blends stubborn liquids, and spreads colors, powders, or actives evenly. Because of that ferocious action, a high-shear line trims hours off the schedule and keeps quality steady from one batch to the next.

The system shines with anything that must be silky, stable, and completely uniform-creams, salad dressings, paint, or liquid polymer. Whether a plant is scaling up or tightening quality brakes, the high-shear blender stands ready.

Core Advantages of Our High-Shear Blender

- Unmatched Mixing Efficiency: Crack the toughest recipes-no more grit in high-viscosity mixes.

- Shorter Processing Times: Slash blending cycles up to 50 percent-keep the line moving.

- Scalable Solutions: Whether you’re starting with a small pilot batch or ramping up to full mass production, this blender keeps pace.

- Wide Power Range: Pick the 1.5 kW unit for light work, or go all the way to 35 kW for heavy-duty processing.

- Custom Voltage Options: Runs on 110 V, 220 V, 380 V, 415 V, 480 V, or 600 V, so hook it up almost anywhere.

- Durable Construction: Food-safe 304 stainless steel is standard, or upgrade to pharmaceutical-grade 316 L when purity counts.

- Low Maintenance: Smooth surfaces and smart design cut cleaning time and keep downtime low.

Taken together, these features help keep your line fast, cost-efficient, and in line with every relevant rule.

Common Applications and Use Cases

Pharmaceuticals:

Emulsify ointments, suspensions, and syrups while meeting strict hygiene rules.

Cosmetics and Personal Care:

Whip up creams, lotions, gels, and serums that feel and look the same every time.

Food and Beverage:

Blend sauces, emulsify dressings, and evenly disperse stabilizers for silky, shelf-stable goodies.

Chemical Processing:

Stir paints, coatings, polymers, and detergents to a steady viscosity and predictable performance.

Biotech and Labs:

Small R-and-D batches grab the same quality as larger runs for faster testing and smoother scale-up.

Picture a beauty company rolling out a brand-new face cream. By mixing the formula in a high-shear blender, each active ingredient blends in completely. That means the cream doesn’t sit on the skin; it sinks in better, stays mixed on the shelf, and keeps customers happier for longer.

Technical Specs & Custom Options

| Parameter | Specification Options |

|---|---|

| Power Output | 1.5KW to 35KW |

| Voltage Range | 110V, 220V, 380V, 415V, 480V, 600V |

| Material | 304 or 316L stainless steel |

| Rotor Speed | Up to 3000 RPM |

| Processing Capacity | Customizable (5L to 10,000L+) |

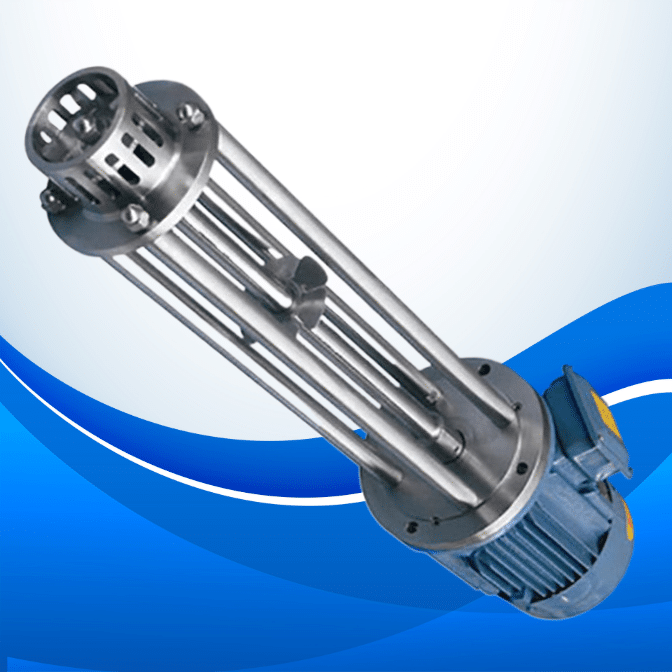

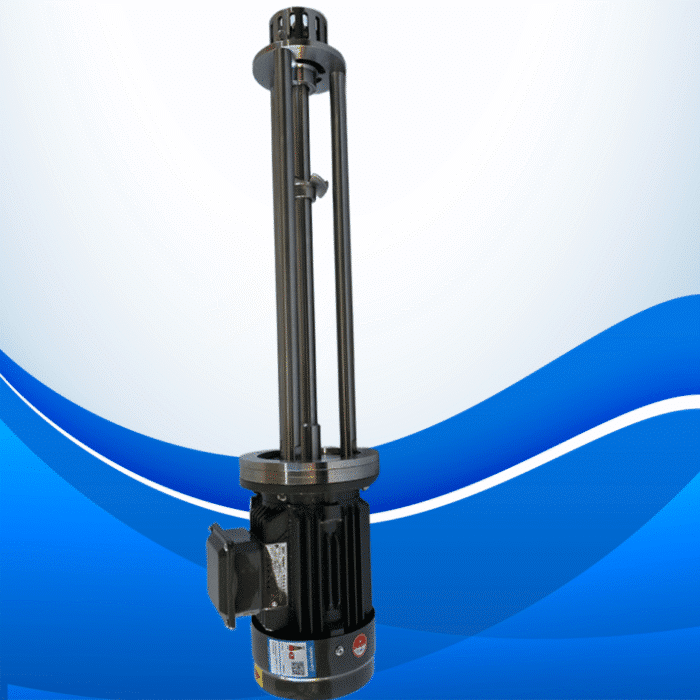

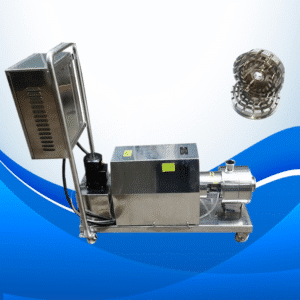

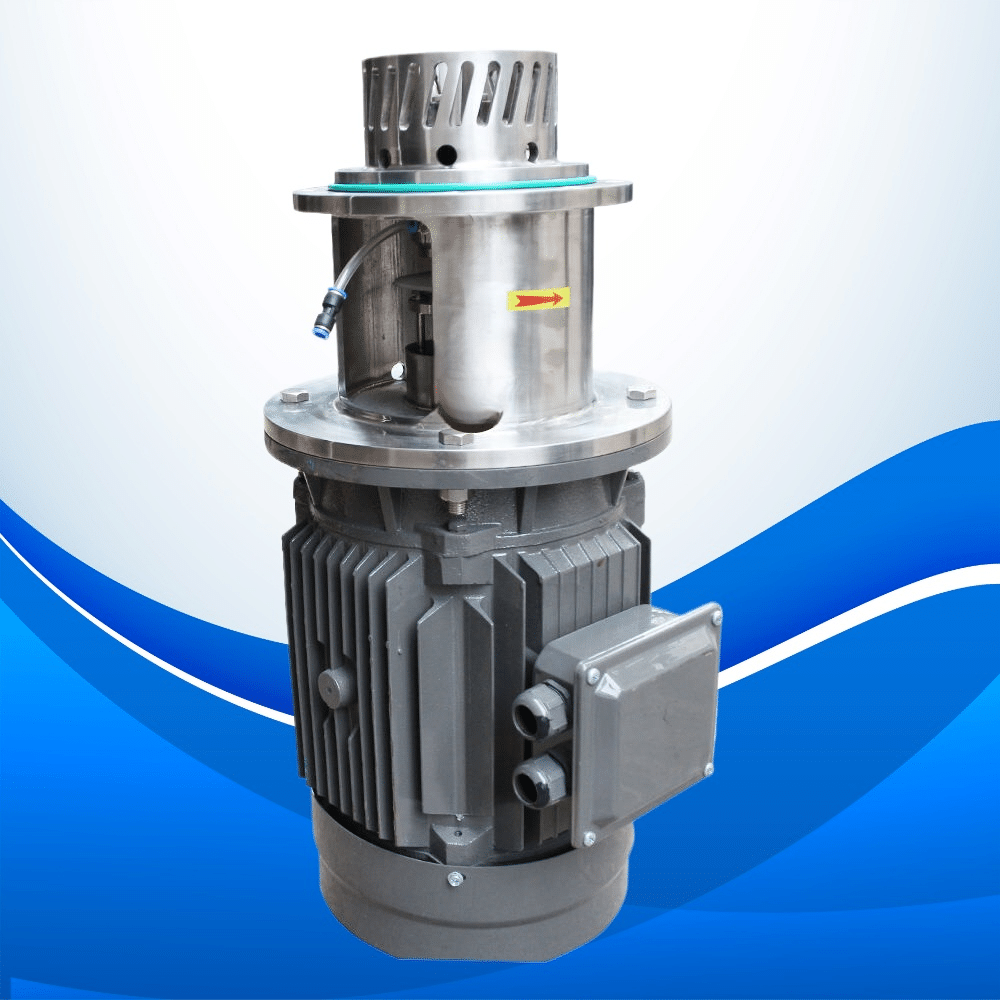

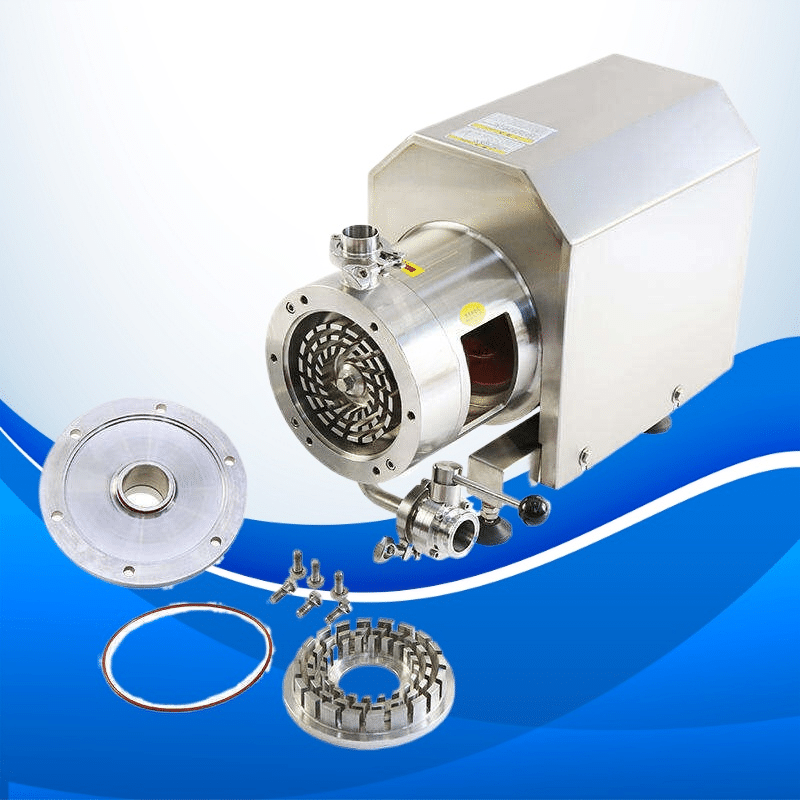

| Mounting Options | In-tank, inline, portable skid-mounted |

| Control Panel | Optional touch-screen HMI with PLC integration |

Because every plant runs differently, our team can adjust every setting. You can ask for a light, mobile version that sits on a cart, or a heavy-duty inline unit for nonstop production; either way, the system fits right into your line.

Why Choose Our High-Shear Blender?

Our high-shear blenders aren’t just powerful-they re-built to last. Constructed to GMP, FDA, and CE guidelines, they keep mixing day after day in tough factories around the world.

With us, you get:

- Custom Design: A machine built just for your recipe.

- Expert Consultation: Engineers who listen and help your team set up.

- After-Sales Support: You get tech help, spare parts, and installation when you need them.

- Global Shipping: Our trusted carriers make sure your order arrives on time, no matter where you are.

More than 30 countries count on our machines to boost output, lift product quality, and cut costs. Whether you’re setting up a brand-new line or tuning an old one, our high-shear blenders give you serious bang for your buck.

Ready to Order or Customize?

Want to supercharge your production with a blender built just for you? Reach out today for a free quote, expert technical advice, and custom setups that fit your workflow.

Let our engineers craft a solution that slips into your plant, whether you work in pharma, food, or any heavy industry.

FAQ – High Shear Blender

Q: What industries benefit most from a high shear blender?

A: Pharma, cosmetics, food & beverage, chemicals, and biotech.

Q: Can I use it for both solid-liquid and liquid-liquid mixing?

A: Yes, it’s great for dispersion and emulsification.

Q: What the difference between 304 and 316L stainless steel?

A: 316L fights corrosion better, making it perfect for sensitive drug and food formulas.

Q: Can I get a unit built for the voltage in my country?

A: Yes, we can make it work anywhere from 110V to 600V.

Q: Once I order a custom model, how soon does it ship?

A: It usually ships in about 2 to 6 weeks, after you pick the setup.