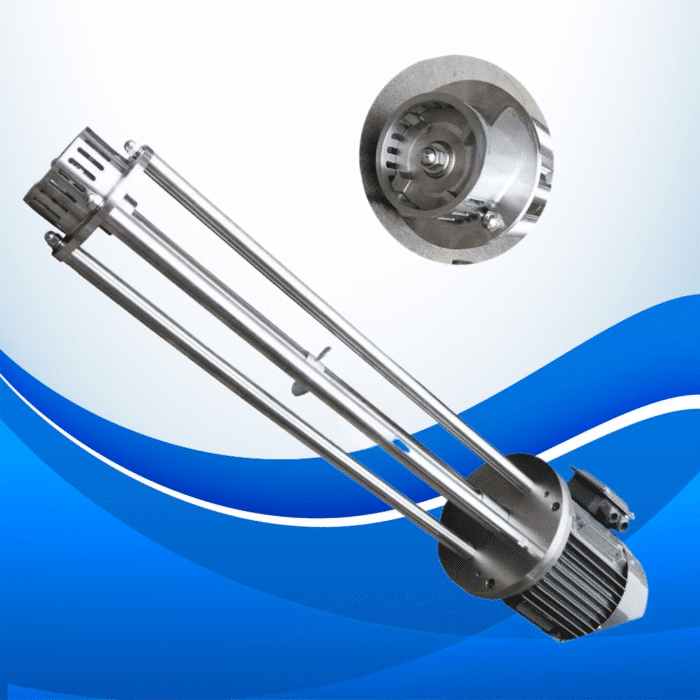

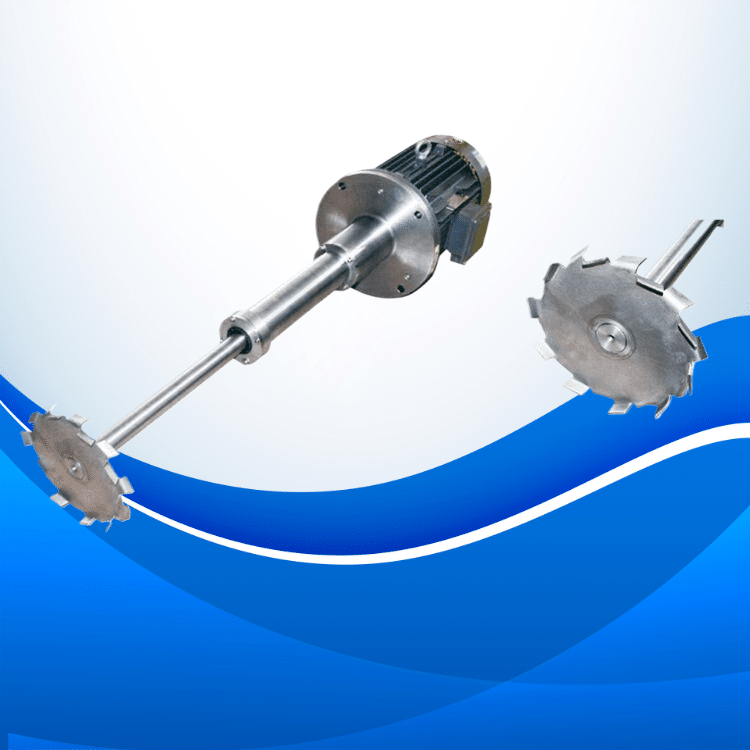

High Shear Batch Mixer for Efficient Industrial Mixing

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$2,100.00

Guaranteed Safe Checkout

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

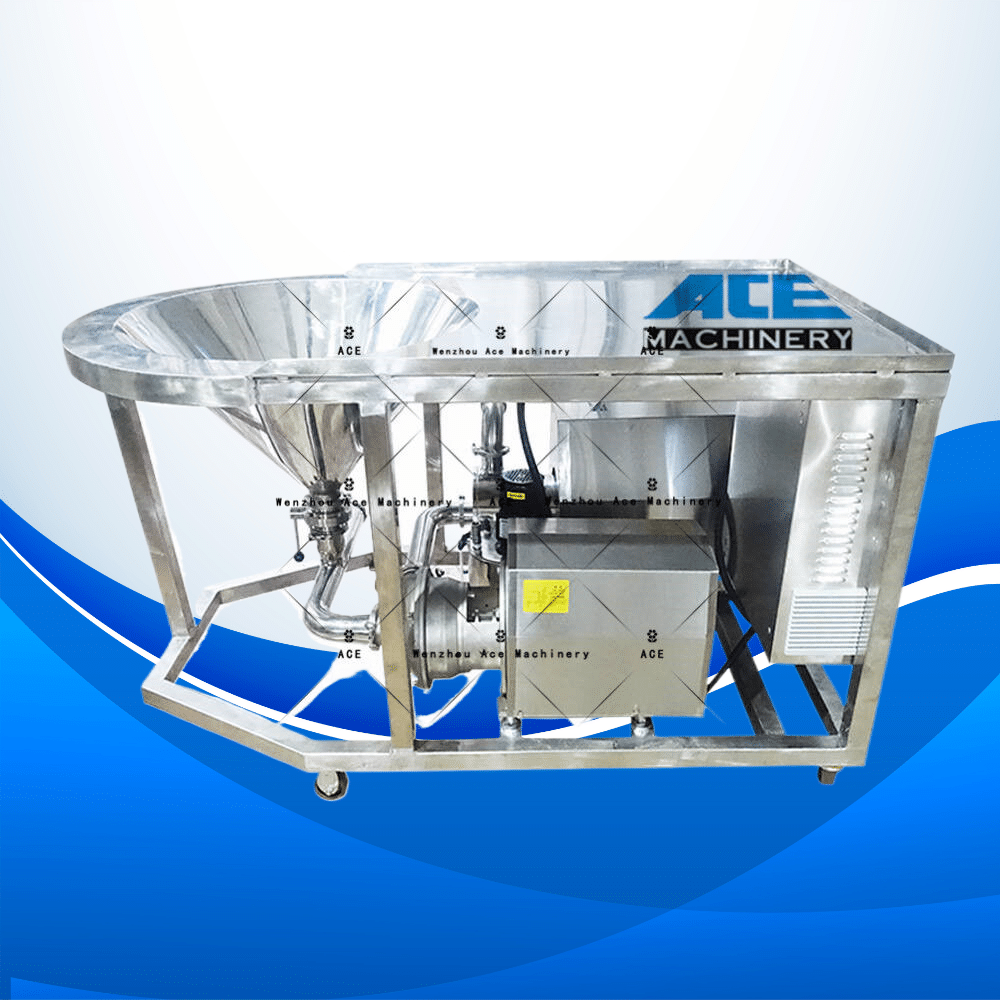

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

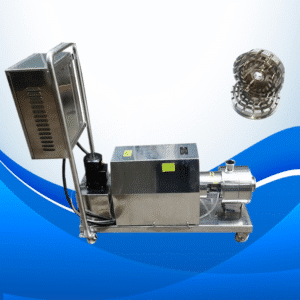

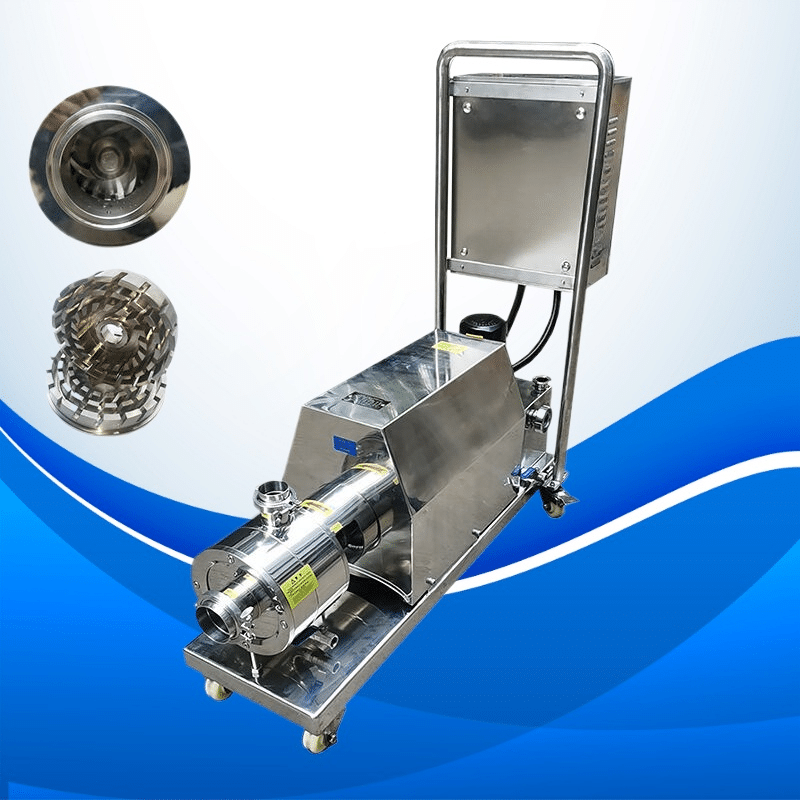

Easy to move and lift

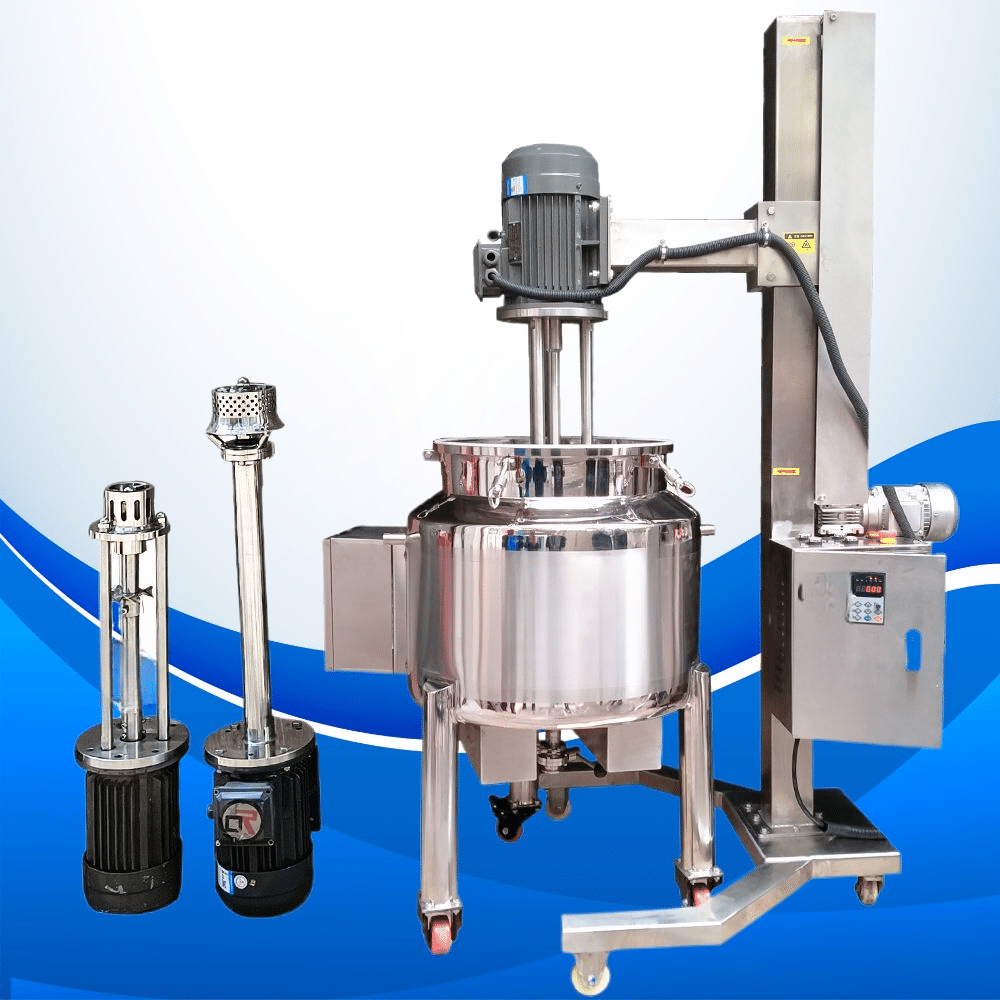

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

High Shear Batch Mixer: Your Go-To Mixer for Tough Jobs

When you can’t afford mistakes in mixing, a high shear batch mixer often sits at the head of the line. Built for precision, long life, and quick tweak-ability, it gives manufacturers the reliability they need for work that demands emulsifying, dispersing, homogenizing, and cutting particle size almost perfectly each time.

🌟 Why Choose a High Shear Batch Mixer?

Knock-Out Mixing Power

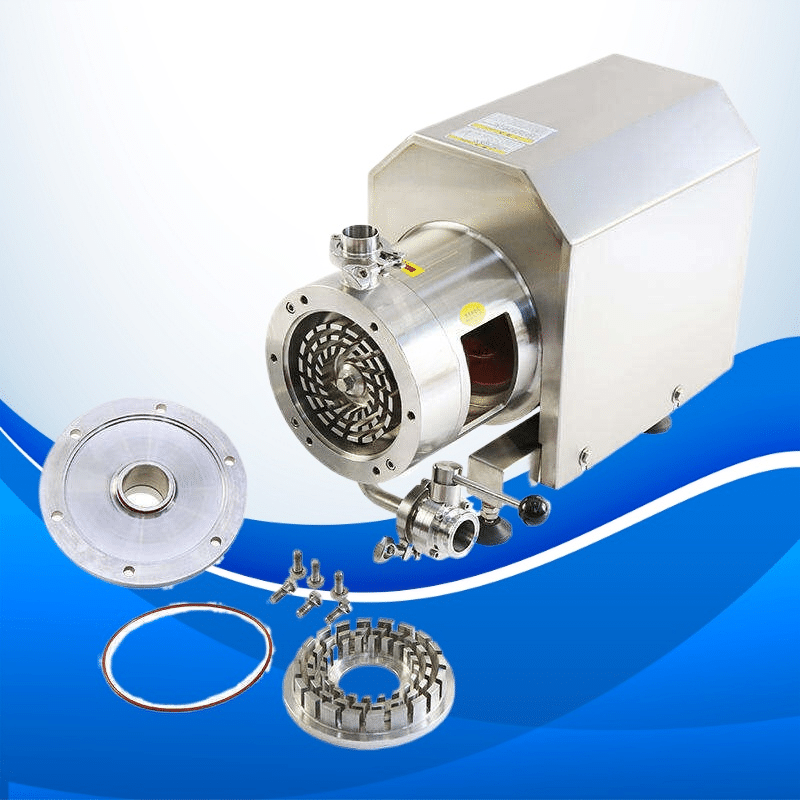

Thanks to a fast-turning rotor and a wall of hard-edged blades, this mixer splits particles before they even settle, leaving you with a steady, smooth batch.

Wide-Mouth Use

From pharmacy creams and spicy sauces to skin lotions and one-off specialty chemicals, the high shear head takes each recipe in stride, no matter how thick or thin.

Engineered Power Choices

Motors from 1.5 kW up to 35 kW let you match strength to batch size, so every stroke pushes the mix without wasting juice or time.

Plug-and-Play Volt Ranges

Whether your plant runs on 110V café circuit or 600V heavy industrial line, the mixer swaps converters quick-lightening worldwide.

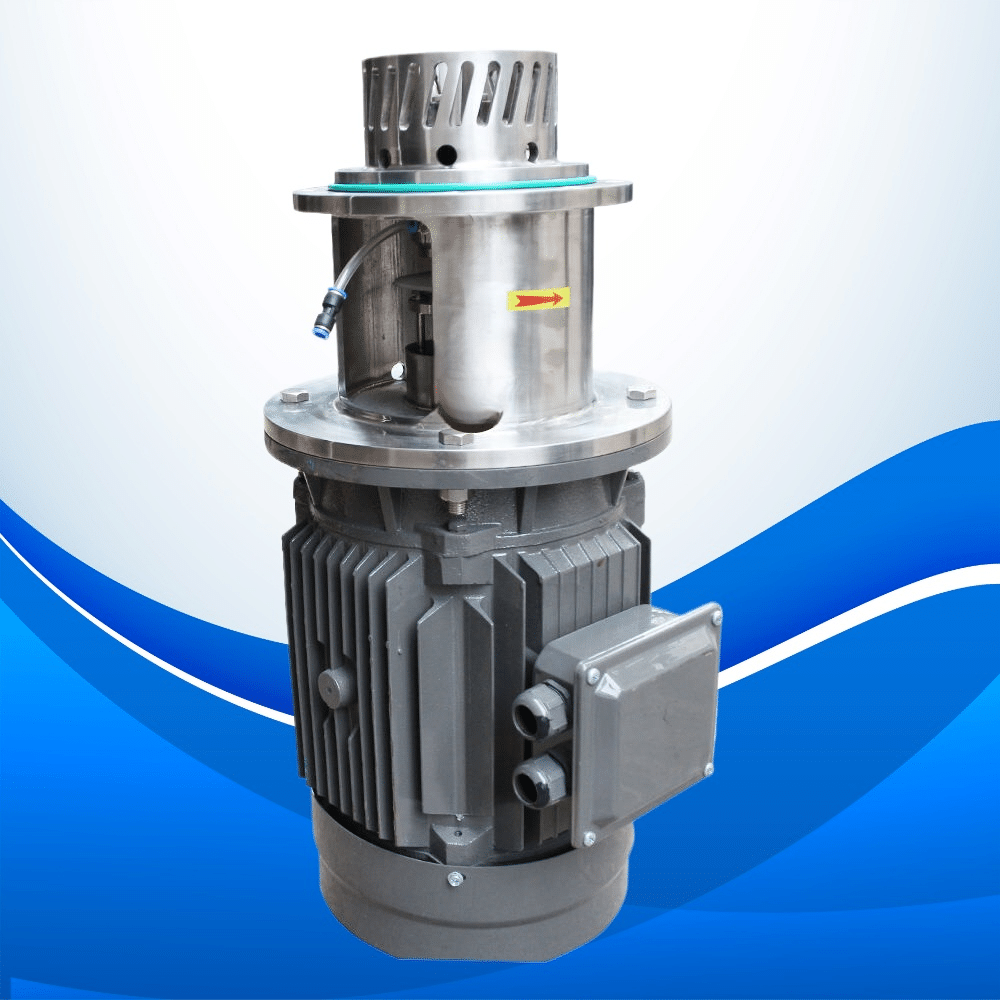

Hygienic, Tough Build

Pick 316L stainless steel for food and pharma rooms, or go with 304 stainless for most factory floors. Either way, you’ll get high corrosion resistance and a surface that’s quick to clean.

Real-World Uses

Pharmaceuticals

Mix creams, gels, and ointments, so each batch looks and acts the same. The system breaks down particles to the right size, giving longer shelf life and better performance.

Food & Beverage

Blend sauces, dressings, and dairy products until textures and tastes are spot-on. Fast mixing cuts time on the line while keeping quality high.

Cosmetics

Lotion, shampoo, or serum comes out air-free, glossy, and super smooth—perfect for delicate, high-end brands.

Chemical Industry

Pigments, resins, or stabilizers end up mixed through your batch in seconds. The system tackles thick liquids and harsh chemicals without breaking a sweat.

📊 Quick Look at Our Tech Specs

- Power Range: 1.5 kW to 35 kW

- Voltage Choices: 110V, 220V, 380V, 415V, 480V, 600V

- Grade of Steel: 304 SS or 316L SS

- Tank Size: Made-To-Order from 20L up to 2000L+

- Speed Control: Upgrade to Variable Frequency Drive (VFD)

- Seal Type: Pick Mechanical Seal or Lip Seal

- Motor Style: Explosion-Proof or Standard Industrial

🛠 Built for Your Day-to-Day Needs

Every plant does things a little differently, so we give you options like:

- Set mix speeds for thin or thick liquids

- Mount the mixer on wheels or bolt it down

- Longer shafts for deep-sided tanks

- CIP-ready parts that meet FDA clean rules

Our engineers chat with you at every step, turning your idea into the smartest, smoothest system.

✅ Why Pick Our High-Shear Batch Mixer?

- Rock-Solid Track Record with hundreds of shops already running it

- Low Upkeep Costs backed by premium parts that last

- Fast ROI because it cuts mixing time and keeps each batch steady

- Quick Help from our team, including training, spare parts, and tech tips

📦 Ready to Boost Your Line?

Buying a high-shear batch mixer isn’t just about steel and motors, it’s about winning in the market. Ask for your tailored quote today and move toward better quality, speedier cycles, and fatter margins.

👉 Reach out for a free chat or book a demo unit.

❓ Common Questions

Q: Can I use this mixer for super-thick pastes?

A: Sure. With a 35 kW motor and optional heavy-duty blades, it easily tackles high-viscosity mixes.

Q: How fast can I get my machine?

A: Stock models ship in 10-15 business days. Custom-builds may take 3–6 weeks depending on options.

Q: Is 316L stainless really needed?

A: For pharma or food work, 316L molds corrosion and stays clean, so we do recommend it.

Q: Will you set it up and train my crew?

A: Absolutely. We send techs worldwide to install the mixer and teach operators.

Q: Can I upgrade later (for example, add speed control)?

A: Yup! Stuff like a VFD, fresh seals, or a bigger motor can be put in down the road when you need it.