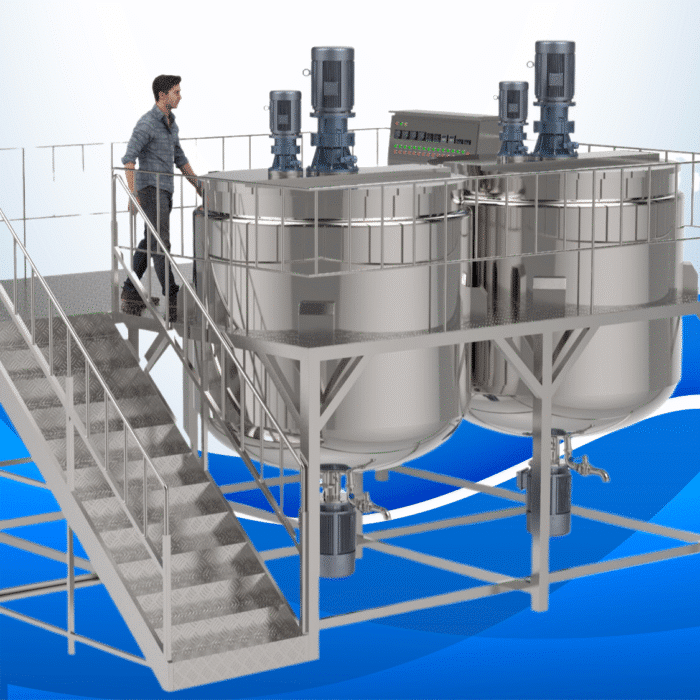

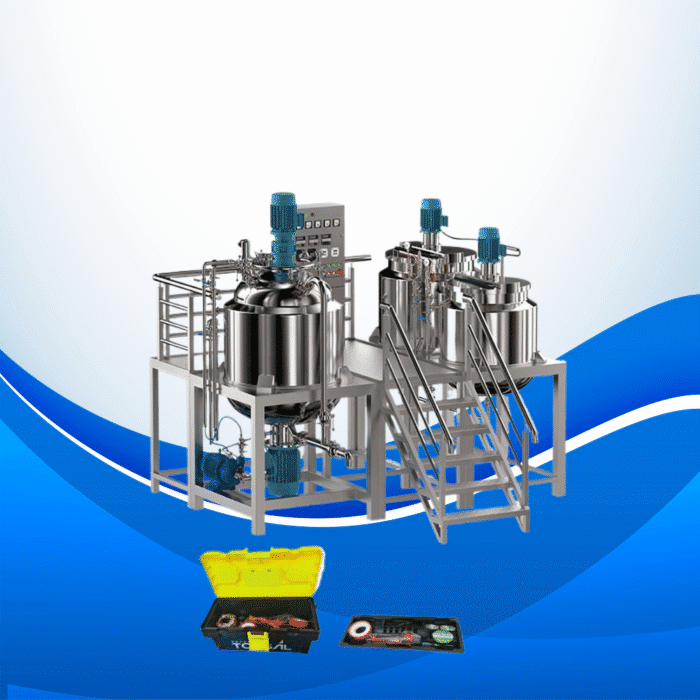

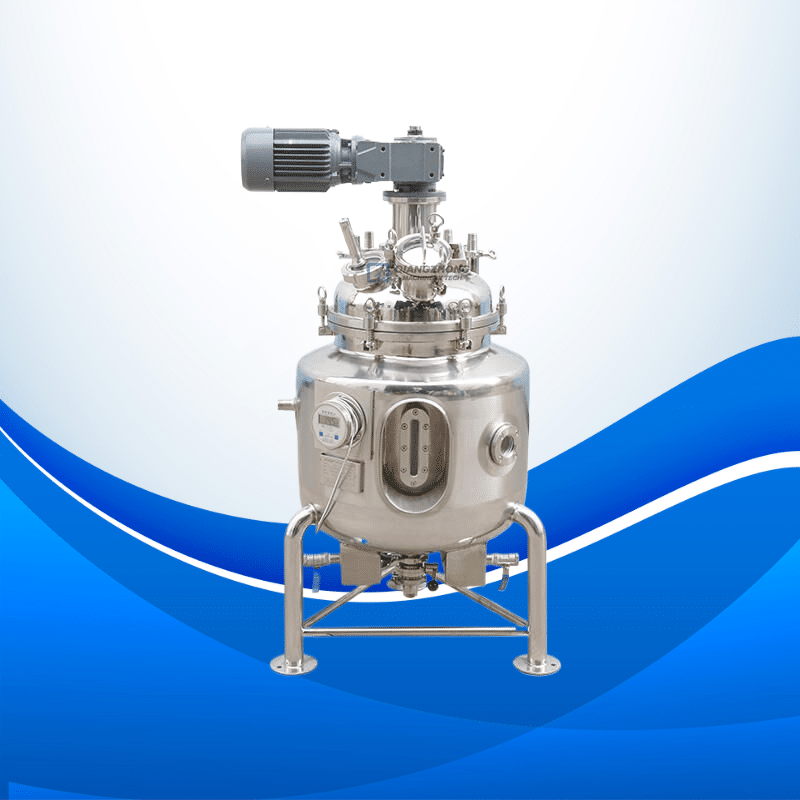

High-Quality Stainless Steel Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,100.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Stainless Steel Mixing Tank: The Right Workhorse for Every Factory Floor

When a batch needs to be mixed, you want the equipment that never lets you down. The Stainless Steel Mixing Tank stands out because it’s built to stay dependable, tough, and energy-smart day after day. No matter if your line fills jars of jam, pumps out pills, blends toners, or stacks drums of detergent, this tank keeps the entire process steady and on schedule.

What Makes the Stainless Steel Mixing Tank a Must-Have?

Rugged Build that Lasts

Crafted from top-grade stainless steel, these tanks shrug off rust, corrosive spills, and the rough handling found in busy plants. Choose between the 316L or 304 grade, and either way, you get years of service even when acids, salts, or aggressive chemicals are around. That extra layer of protection means fewer shut-downs for repairs and less worry about what the next batch might corrode.

Fits Many Lines and Rooms

This mixer has earned a spot in just about every plant, including:

- Food and Drink: Mixing sauces, juices, or powdered blends while hitting every hygiene rule.

- Pharma: Blending active ingredients into syrups, gels, or wipes in a sterile, repeatable way.

- Chemicals and Cosmetics: Mixing creams, cleaners, and dyes exactly and without mess.

- Petrochemical: Keep heavier liquids, oils, and chemicals held in, stirred, and stored—with no leaks.

- Wastewater Treatment: Chemicals and sludge are homogenized for easy handling and disposal.

DESIGNED FOR YOUR NEEDS

Every schedule and floor layout is different. Our Stainless Steel Tank can be tailored with:

- Voltage Range: Pick any standard voltage—110V, 220V, 380V, or 600V—so it plugs right into your plant.

- Power Options: From small batches to full production, choose a motor between 1.5KW and 55KW.

- Material Choice: Use 316L or 304 stainless based on the process and what liquid or slurry goes inside.

EFFICIENCY THROUGH PRECISE MIXING

Minimal energy wasted, every load gets a uniform blend. Clean blades tackle liquids, solids, or pastes, and the smart motor cuts mix time. Faster batches lift productivity and free up floor time for other work.

Easy Maintenance and Cleaning

Keeping things clean is a big deal in places like restaurants and drug factories. Because the inside of the stainless steel tank is super smooth, leftover bits wash away quickly, stopping germs before they start and meeting all the rules. Its stainless surface doesn’t stain or hold onto smells, so you can switch between jobs without carrying old tastes or odors along.

Space-Saving Design

With a low-profile, user-friendly shape, the Stainless Steel Mixing Tank slips into your line without crowding the floor. Choose from several sizes and get a unit that fits your room perfectly.

Applications and Real-World Usage Scenarios

Picture a busy sauce plant, tossing together chillies, oil, and spices in one of the tanks. Its careful mixing action means every jar of dressing tastes the same, and the long-lasting 304 stainless steel survives wash-downs day after day.

In pharma labs, blending powders for pills or liquids must be spot-on. The tank’s quiet, energy-saving motor lets operators fine-tune speed, so each batch comes out reliable.

The Stainless Steel Mixing Tank is a real workhorse in the chemical and cosmetics worlds, too, gently blending thick or delicate ingredients. Whether you’re whipping up lotions, pouring oils, or mixing tricky chemicals, this tank keeps the process fast, clean, and secure.

Technical Specifications

- Material Options: 316L or 304 stainless steel

- Voltage Range: 110V to 600V (we can build what you need)

- Power Range: 1.5 kW to 55 kW

- Capacity: Sized right from lab benches to full-factory tanks

- Mixing Mechanism: Adjustable-speed motor for smooth blending

- Design: User-friendly, easy-clean, slots right into your line

Why Choose Our Stainless Steel Mixing Tank?

- Reliability: Tough build that keeps mixing even under heavy use.

- Customization: Pick the voltage and wattage that fit your setup.

- Industry-Specific Design: Works well in food, pharma, chemicals, and beyond.

- Hygienic and Safe: Meets all health rules, so your team and product stay protected.

- Increased Efficiency: Finishes jobs faster while trimming energy bills.

Order Your Stainless Steel Mixing Tank Today

Whether you want a one-of-a-kind setup or a ready-to-go model, our Stainless Steel Mixing Tanks are built to work hard and look good. Get in touch to explore tweaks you need, ask about costs, or check delivery times.

FAQ:

What size tank should I order?

The best size depends on how much you produce and how you mix. Call or email, and we’ll match a tank to your job.

Can I choose the mixing speed?

For sure. With a variable-speed motor, you set the pace that fits each batch.

Is the tank easy to maintain?

Absolutely. The brushed stainless finish wipes clean fast and stays spotless with little effort.

What’s the difference between 316L and 304 stainless steel?

316L fights rust better in salty or acidic air, so pick it for tough work areas; 304 suits most other jobs.

Take the next step in your operation with a tank that combines smart design and sturdy build.