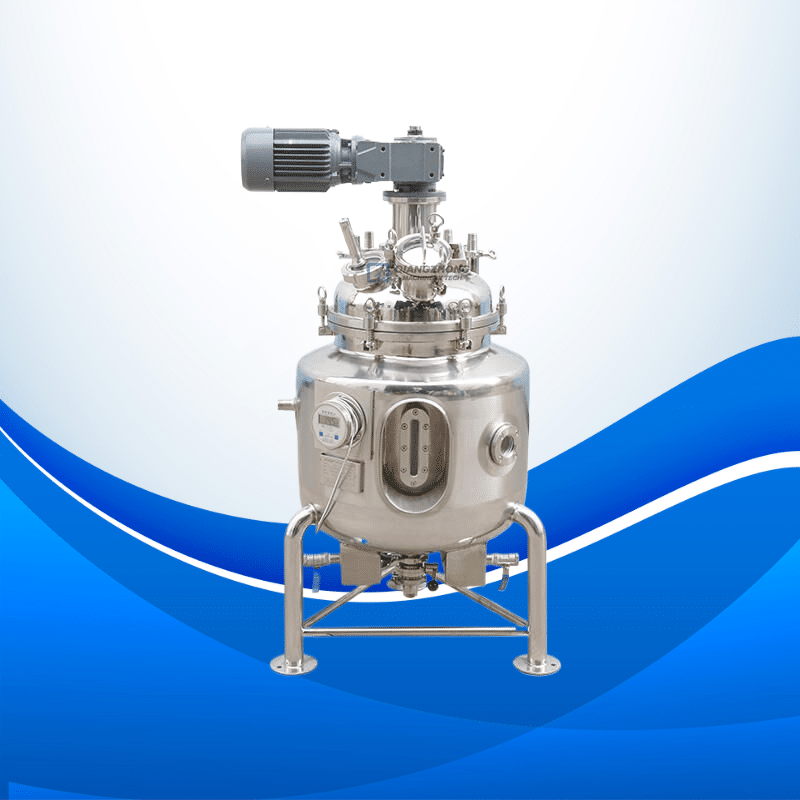

High-Quality Stainless Steel Liquid Mixing Tanks

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,220.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Stainless Steel Liquid Mixing Tank: The Go-To Tool for Every Heavy-Duty Mixer

From busy bakeries to labs making the latest skincare craze, many factories depend on mixers that never quit. The Stainless Steel Liquid Mixing Tank delivers steady blending, rugged strength, and the bit of smart tech that lets it pivot between jobs. With options for size, power, and finishing, the unit fits almost any recipe while saving time and energy.

Solid Features That Count

Built to shrug off dents and stains day after day, this mixing tank gives plant managers the peace of mind they crave. Here are the highlights that keep it at the front of the crowded equipment field:

Tank-Grade Steel Inside and Out

Offered in tough 304 or higher-grade 316L stainless, these vessels laugh at rust and keep liquids safe. Choose 316L for pharma or food lines that demand squeaky-clean, splash-proof walls every minute.

Flexible Power and Voltage Choices

Our mixing tanks are fitted with motors that can be switched between 1.5 kW and 55 kW, so they work well for tiny test runs or huge factory lines. You can also pick from voltages of 110 V up to 600 V, making the tank easy to plug into almost any plant around the world.

Precise Mixing Technology

Every tank features a modern agitation system that blends liquids of all thicknesses evenly. From water-thin syrups to heavy creams, the setup delivers the same smooth, consistent quality without hotspots or lumps.

Custom Size and Layout

No two production floors are alike, so our stainless-steel tanks can be tailored to your exact space and process. You decide the tank volume, inlet ports, and even blade angle, and we build a unit that works best for you.

Built-to-Last Durability

Made of heavy-grade stainless steel, these tanks stand up to years of tough use without rust or serious denting. Whether you run them non-stop or batch once a shift, the sturdy build cuts down maintenance cost and protects your long-term investment.

Applications of Stainless Steel Liquid Mixing Tanks

Because they look good and work hard, stainless-steel liquid mixing tanks show up in many places. Here’s a peek at a few jobs and industries that love what they can do:

Food and Beverage

Whether blending powders, thinning sauces, or folding oils into drinks, the tank keeps things tasty and clean. Dairy makers, condiment factories, and fizzy-drink plants all trust the stainless finish to stay sanitary and mix fast.

Pharmaceuticals

Drug manufacturers depend on steady blending if every pill or liquid is to be the same. Our steel tanks stir solutions, suspensions, and syrups while watching temperature, humidity, and other settings.

Cosmetic and Personal Care

Creams, scrubs, and shampoos must feel and look alike in every bottle, and the tank helps deliver that smoothness. Polished steel, plus options like built-in pumps or heating, meets tough rules and keeps formulas safe.

Chemical Processing

Corrosive liquids work best when they swirl together, and our sturdy tank handles acids, bases, and solvents without rusting. Extra seals, thick walls, and vents let operators mix harsh materials over the long haul.

Water Treatment

Stainless steel mixing tanks sit at the heart of water treatment plants, blending chemicals with water so it comes out clean and safe. Because they resist rust and damage, the tanks keep working even when chemicals or temperatures change.

Specifications and Customization Options

Our Stainless Steel Liquid Mixing Tank comes with plenty of choices so you get exactly what your plant needs:

- Capacity: Pick anything from a compact 100 liters to huge models holding several thousand liters.

- Material Options: Go with 304 stainless steel for regular jobs, or upgrade to 316L if your industry demands top-notch corrosion and contamination protection.

- Power Range: Motor sizes stretch from 1.5KW to 55KW, giving you room to match power to the job.

- Voltage Options: Receive your tank wired for 110V all the way up to 600V, so it fits your local grid with no hassle.

- Mixing Speed: Speed settings are dialed in individually, letting you lock in the exact stir rate that gets the right blend.

- Design Features: Choose the agitator type, add baffle plates, fit heating jackets, and more—every extra made for your unique mix.

Why Pick Our Stainless Steel Liquid-Mixing Tank?

- Built Tough: Made for round-the-clock work, these tanks shrug off stress and stay online longer, cutting maintenance bills and lost production hours.

- Clean by Design: Bright, polished walls and smart, easy-to-reach parts mean a quick wipe-down passes the strictest food, drug, and beauty-tile tests.

- Smart Energy Use: Match motor size and speed to each job, and the tank runs cooler and cheaper, putting extra dollars back in your pocket.

- Simple Controls: Color screens, clear indicators, and step-by-step guides mean new hires master the panel in a few shifts, freeing you from constant training.

- Your Tank, Your Way: From foot-diameter to heating-coil height, we listen and build exactly what you need, so the system fits your plant, not the other way around.

Ready to Boost Your Mixing Line?

Level up your operation with our Stainless Steel Liquid-Mixing Tanks. Tough, clean, and always built to your envy-size spec, they shine in food, pharma, and cosmetics. Grab yours today and turn reliability into production hours, not paperwork.

Give us a shout today for a quick quote or to chat about what you really need. We’ll work with you to sketch out a stainless-steel mixing tank that fits your project. Whether you’re after a standard model or something one-of-a-kind, our team will guide you through each step.

Common Questions About Stainless Steel Liquid Mixing Tanks

Q1: What is the difference between 316L and 304 stainless steel?

A1: 316L has extra nickel and molybdenum, which makes it much tougher against rust so it suits pharmacies and food lines. 304 is still strong and costs less, so it’s great for places where the air and water aren’t as harsh.

Q2: Can I customize the mixing speed and power?

A2: Absolutely. Motors from 1.5 kW up to 55 kW let you pick the spin you want, and speed-control panels put the dial in your hands.

Q3: Are the tanks easy to clean?

A3: For sure! Smooth welds, rounded corners, and big access lids mean your sanitizers can slide in fast, keeping food or med lines trim and safe.

Q4: Can I use the tank to mix both thick and thin liquids?

A4: Yes, you can. Our smart mixing system handles light liquids and heavy mixes alike, so you always get an even blend no matter how thick or thin the stuff is.