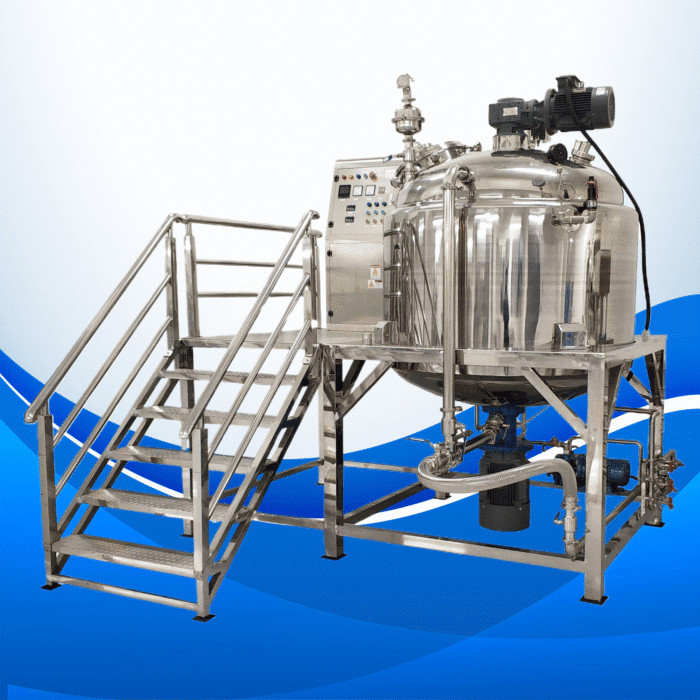

High-Quality Soap Mixing Tank for Efficient Soap Production

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,300.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Soap Mixing Tank: The Secret Weapon for Faster Soap-Making

If you run a busy soap workshop or a big factory, one machine you really can’t do without is a tough, dependable soap mixing tank. Whether your line-up includes scented bars for the bathroom, trendy face cleansers, or even handmade artisan recipes, the right tank speeds things up and stops problems before they start. Built to last and loaded with smart features, our tanks whip every batch into a silky, even mixture that pours easily into molds and holds its shape. In the short sections that follow, we break down what these tanks can do, where you can use them, and why adding one to your shop will boost your bottom line.

1. Product Overview of the Soap Mixing Tank

Think of the soap mixing tank as the heartbeat of any soap-making shop. By gently stirring together oils, lye, and special extras, the tank turns separate ingredients into a smooth batter for bars or liquid soap. If the mix isn’t even, you’ll end up with patchy colors, odd smells, or rough surfaces, and nobody wants that after a long pouring day. Our tanks are built in several sizes and shapes, each powered between 1.5 KW for a hobby line and 55 KW for a bustling factory, so there’s a fit whether you make ten bars a week or thousands every hour.

Key Features:

- Customizable Power: Pick any motor from 1.5 KW to 55 KW, matching electricity needs and output goals, so you never waste energy or struggle with weak mixes.

- Voltage Flexibility: Tanks run on 110 V, 230 V, or even up to 600 V, meeting local plugs and coils worldwide while keeping operators safe and circuits stable.

- Material Options: Go for 316 L stainless steel when the shop has corrosive fumes or salty spills, or 304 steel when strength matters, but budgets are tighter.

- Durable & Safe: Heavy-duty seals, wear-resistant blades, and reinforced frames shrink downtime and surprises, letting staff run the line with confidence and no extra weekend repairs.

Our flexible mixing tanks can handle almost any ingredient you throw at them, and they come packed with smart features that keep every batch consistent and on-target.

2. Soap Mixing Tanks in the Real World

Soap mixing tanks show up in many workshops, from huge factory floors to cozy kitchen-table businesses. Here are the main ways people put them to work:

Big-Batch Soap Factories

When a company needs to crank out tons of soap every hour, our tanks step in to keep the flow steady and the mix the same from the first drop to the last. A beefy motor spins batches that would tire out a home blender, so liquid or bar soap stacks up fast without lost quality. They tackle all kinds of recipes-even those packed with special extras like scents, color beads, or scrubbing bits.

Beauty and Body-Care Makers

Shampoos, shower gels, and creams demand the same uniform feel as soap, which is why many cosmetic lines keep a tank close by. Small changes in mix time or heat can turn a glossy body wash lumpy, so these tanks let makers add oils, moisturizers, and cleansing agents in one smooth move. With gentle, adjustable speed and built-in sensors, the machine guards against clumps, bubbles, or layers that spoil a customer first squeeze.

Artisan Soap Makers

Smaller soap shops and artisan makers also find that a dedicated soap mixing tank makes a big difference in their work. Because they often use special recipes and high-quality ingredients, they need to measure and heat everything precisely. With several tank sizes available, a studio can whip up just a few dozen bars or a larger mini-batch, matching supply to demand. Being able to tweak the stir speed and the temperature on the fly lets these makers turn out luxury bars that grab attention on crowded shelves.

Chemical Industry Applications

Across the wider chemical field, soap mixing tanks serve in countless other recipes where accuracy still matters. Thanks to heavy materials and rugged parts, our tanks keep running smoothly even in plants where thick liquids and stricter safety rules are everyday concerns.

Main Advantages of Using a Soap Mixing Tank

- Efficient Mixing: Cutting-edge mixing gear turns every batch into a smooth, well-blended product in far less time. Uniform distribution of oils, lye, and scents means fewer do-overs, less wasted materials, and bars that look and feel the same from the first box to the last.

- Customizable Design: Because every soap maker has a different recipe, we let you shape the tank to fit your business. Want a larger heating element, extra insulation, or fittings in a special spot? No problem.

- Durability and Reliability: Crafted from premium stainless steel-316L or 304-each tank shrugs off daily scrapes and spills.

- Hassle-Free Operation: Every mixer arrives with straightforward dials, emergency stops, and color-coded lights, so no advanced training is required.

3. Key Specifications and Customization Options

Buying a soap mixing tank means making sure it fits your shop and your vision. Start with these core numbers that guide your order:

- Power: Available from 1.5 kW for cottage makers all the way up to 55 kW for high-volume plants.

- Voltage: You can pick a model that runs on 110V, 230V, or all the way up to 600V, so it will fit whatever electrical setup you have at home or overseas.

- Materials: Go with tough 316L stainless steel if salty air or chemicals might be around, or choose 304 steel when you want solid strength at a friendlier price.

- Mixing Speed: An easy dial on the front lets you crank the mixer up or down, so you blend exactly how thick or thin your recipe calls for.

- Heating Options: On some versions, built-in heaters help you keep your soap blend at the right warmth during every single batch.

These choices work together, giving you a tank that fits your workshop, whether you make a few bars a week or tons for a major brand.

4. Why You Should Buy Our Soap Mixing Tank

If you want soap that smells, lathers, and looks the same jar after jar, a reliable mixing tank is the first tool you should add to your line. Engineered from heavy-duty parts, our tanks shrug off bumps, the heat of continuous blending, and even the odd splash of colorant. Best of all, every unit is made to order in our factory, so it arrives ready to streamline your setup.

Boost Your Production Efficiency

Once the tank is plugged in, you’ll notice the difference. A precise mixer cuts time spent stirring by up to forty percent, which pays for the machine in a few extra batches. Pair that with optional heating, automatic timers, and digital speed readouts, and you get a process that almost runs itself. Less guesswork means fewer off-spec batches, less leftover oils, and real savings on labor and materials every production day.

Durable & Long-Lasting

Constructed from tough 316L and 304 stainless steel, our soap mixing tanks are designed to keep running smoothly for years, even in busy or rough settings.

Customization for Your Needs

Every soap shop or factory has its own set-up and goals, so we offer complete freedom to choose the tank s power rating, voltage, and even the steel grade.

Don’t miss the chance to boost your line and save money. Reach out today, and well plan a soap mixer that matches your flow. Place your order and feel the lift in your plant’s speed.

Common FAQs:

- What size soap mixing tank do I need?

The right size really depends on how many bars you make each day. Small crafters usually go with a 1.5KW to 5KW unit. Bigger plans might need something closer to 55KW. - Can I use this tank for other chemical mixing purposes?

Absolutely! Our tanks are flexible tools, and they happily mix lots of liquids, from colorants to cleaners, so they can work in other lines. - How easy is it to clean the tank?

Our fish tanks have smooth sides, snap-open lids, and removable parts, so you can wipe them down or take them apart in minutes and keep everything really clean. - Do you offer international shipping?

Absolutely! We ship to every corner of the globe, and each tank can be set up for your local voltage and plug type, so you get a system that works right out of the box.