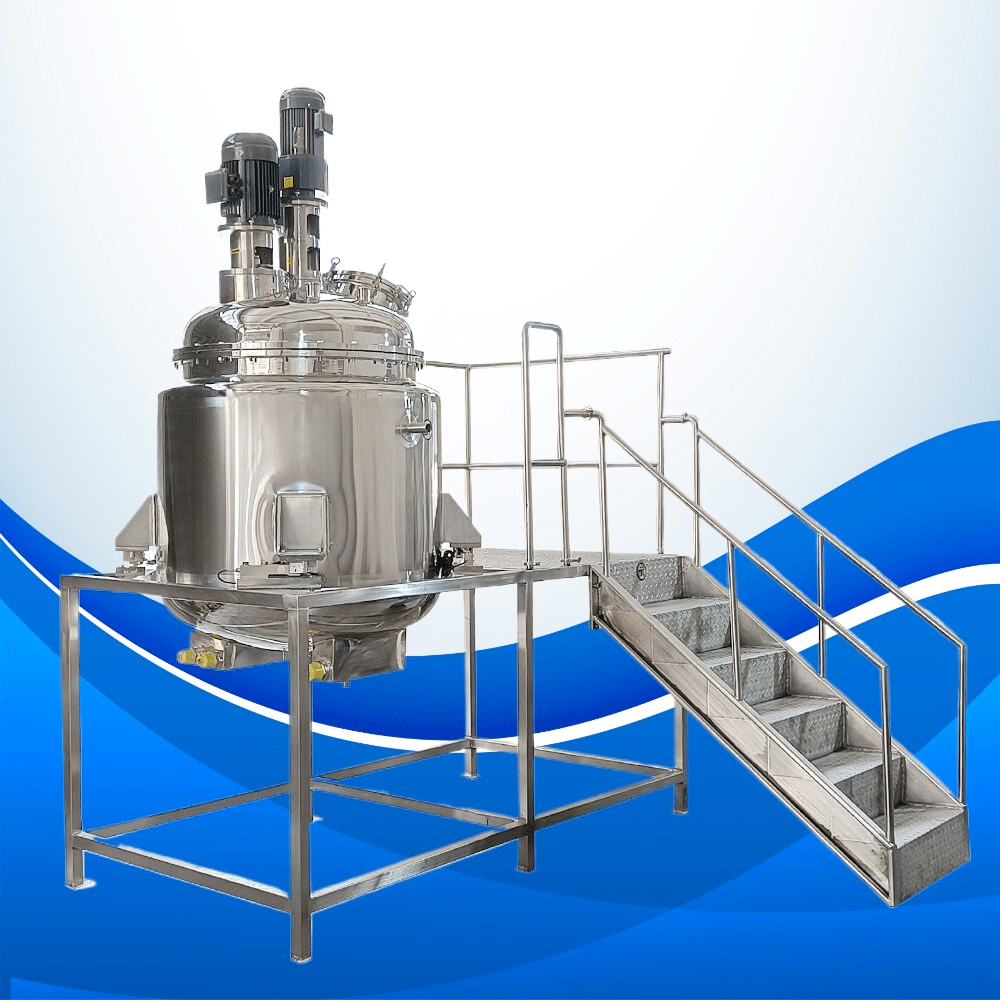

High-Quality Pharmaceutical Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,900.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Pharmaceutical Mixing Tank: The Easy Way to Keep Every Batch the Same

When it comes to making medicines, shots, or health supplements, every step has to be exactly right. The pharmaceutical mixing tank helps factories do that by blending powders, liquids, and other ingredients evenly while cutting the chance of germs getting in. Whether production is on a small bench or a huge factory floor, a solid mixing tank keeps every batch uniform and safe.

Keep reading to learn what these tanks can do, where they fit in the operation, and how they can boost output without sacrificing quality.

Key Features and Specs of the Pharmaceutical Mixing Tank

- Customizable Voltage Options (110V-600V)

- Adjustable Power Range (1.5KW to 55KW). Whether you need a gentle stir for a small pilot run at 1.5 KW or full industrial muscle at 55 KW, the mixing tank suits every scale and keeps the process fast, freeing up time for other tasks.

- Material Options: 316L and 304 Stainless Steel. To match the strict cleanliness and toughness rules in pharma, the tank comes in either 316L or 304 stainless steel.

- Precision Mixing and Homogeneity. Designed for powders, liquids, suspensions, and emulsions, the tank mixes with such steadiness that every batch looks and behaves the same, giving makers confidence that every tablet or bottle meets the highest safety and effectiveness standards.

- Easy to Clean and Keep Running. Because the pharmaceutical world is tightly regulated, keeping equipment clean and sanitary is a must. Our mixing tank comes with removable parts and smooth surfaces that let you wipe it down quickly between batches. That saves time, cuts downtime, and keeps you on the right side of GMP rules.

Where You’ll Find the Mixing Tank On the Job

Because it’s so flexible, the pharmaceutical mixing tank fits a bunch of different drug-making tasks. Check out a few everyday jobs it handles like a champ:

Oral Drug Production

Whether you’re making tablets, capsules, or syrups, the tank blends active ingredients and excipients evenly, so every dose hits the mark.

Injection Solutions

For shots and drips, a uniform mix means safety. The tank keeps liquid formulas homogenous, stopping problems with strength or quality before they start.

Topical Preps

Creams, ointments, and lotions need gentle mixing to get the right feel. Our pharmaceutical tank does that while protecting fragile ingredients from heat or shear.

Nutraceutical Manufacturing

Because more people are popping pills and munching on vitamin-fortified snacks every day, our pharmaceutical mixing tank now handles these products, too, making sure each batch is blended the same and that nothing gets left out.

Why Choose Our Pharmaceutical Mixing Tank?

Enhanced Mixing Efficiency

Built for speed, the tank mixes faster, fills orders quicker, and leaves you with a higher-quality finish. Its motor-driven paddle spins gently enough to work with high- and low-viscosity blends, so even the most tender ingredients stay whole and well-integrated.

Customizable Design

No two factories work the same way, so our tank can be tweaked in power, size, and material until it fits yours perfectly. You end up with a tool that wastes neither time nor energy because it only does what your operation actually needs.

Regulatory Compliance

Pharma plants live under a mountain of rules—good manufacturing practice, FDA, EMA—and our tanks are built to obey all of them. That way your process stays legal and your customers can trust that every capsule or bar is both safe and effective.

Long-Lasting Durability

We built the pharmaceutical mixing tank to last, and it shows. Quality 316L stainless steel fights off rust, scratches, and damage from tough chemicals, so you spend less time fixing the tank and more time using it.

How the Pharmaceutical Mixing Tank Will Elevate Your Production Process

Picture a busy production line where every batch is mixed exactly the same way and no one has to babysit the equipment. That is what our tank offers. While it handles the mixing, your crew can tackle other critical jobs, cutting the chance of contamination and boosting output.

Our tanks also sip energy instead of chugging it, so you keep performance high while bills stay low and your carbon footprint shrinks.

Ordering and Customization Options

No two businesses are alike, so we let you tweak nearly every detail of your mixing tank. Whether you need a certain voltage, motor size, or special finish, our engineers will partner with you to design a unit that fits your line and your budget.

Ordering your tank is easy—just reach out to our sales team, and we’ll walk you through every step to set up the perfect mixing unit for your pharmacy line. We also provide full after-sale support and can install the tank so it runs at peak performance right from the start.

Frequently Asked Questions About Pharmaceutical Mixing Tanks

1. What is the biggest tank you offer?

Every unit is built to order, so we can size it to fit your output. Models range from tabletop prototypes to massive floor pads used in full-scale plants. Give us a call for exact volumes.

2. Does the tank need a lot of upkeep?

Not at all! The design has smooth seals and removable parts, making cleaning quick and hassle-free for your operators.

3. How quickly will you ship the tank?

Lead time depends on the custom options you choose and where you’re located. In most cases, you can expect shipment in about four to six weeks after we finalize the order.

4. Can the tank mix liquids and powders?

Yes, it handles both with the same reliability, giving you uniform blends no matter the formula you pour in.

5. What kind of help can I get after I buy?

After you buy from us, we give you full support, from helping set up the equipment and training your team to answering any tech questions down the road.

Conclusion: Invest in the Future of Pharmaceutical Manufacturing

Our mixing tank is a must-have for any drug factory. Because you can tweak its features, it works fast, and it fits many recipes, you can trust that every batch meets the highest quality standard.