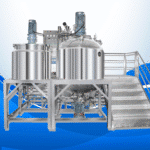

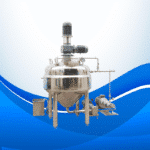

High-Quality Mixing Tanks for the Pharmaceutical Industry

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,888.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Product Description: Mixing Tank for the Pharmaceutical Industry

When it comes to making medicine, every drop counts. That’s why companies look for tools that blend quickly, quietly, and with zero surprises. Our mixing tank does just that, mixing powders and liquids so every batch has the same strength and quality. From active pharmaceutical ingredients (APIs) to excipients and other compounds, this tank meets the tough rules factory floors live by.

Key Features & Advantages

Customization for Optimal Performance

No two labs or plants are exactly alike, and neither should their equipment be.

Our mixing tanks can be shrunk, stretched, or fitted with the bells and whistles you ask for, whether you need a clean-room size unit or a bigger version for full production.

Material Options: 316L and 304 Stainless Steel

Stainless steel isn’t just a finish; it’s the shield that keeps your mix safe and the workers healthy.

- Choose 316L for jobs that sit front and center under a microscope: It’s almost immune to rust and survives years of harsh cleaning.

- Pick 304 when the job is less demanding, but you still want peace of mind and a wallet that doesn’t scream.

Power Choices from 1.5 kW to 55 kW

Mixing tanks need different amounts of power based on batch size, materials, and how fast you want to stir. To match each job, our tanks offer motor ratings from 1.5 kW up to 55 kW, so you only use the energy you really need.

Voltage Choices: 110 V to 600 V

We build tanks for just about every voltage, from 110 V single-phase up to 600 V three-phase, meaning they’ll plug right into your current setup. That cuts down on costly rewiring and helps you keep production moving.

Steady, Efficient Mixing

Whether you mix liquids, powders, or thick suspensions, our pharmaceutical tanks deliver even, repeatable results. Optional heating, cooling, and tight speed control let you lock in the right temperature and viscosity from start to finish.

Clean-First Design

Because every batch must be germ-free, each tank has smooth welds, quick-clean ports, and steam-proof seals that keep bugs out. With these features, you can spend less time sanitizing and more time making safe, high-quality products.

Applications

Mixing tanks fit lots of jobs in a drug plant, such as:

- API Production: blending active ingredients with other compounds to make the final medicine.

- Excipients Mixing: combining excipients with APIs for tablets, capsules, or oral solutions.

- Topical Formulation: preparing creams, ointments, and gels.

- Liquid Medicines: keeping suspensions and solutions uniform.

Because they flex from small test runs to huge batches, many sites rely on mixing tanks for every step from lab to market:

- Batch mixing: blending ingredients in chunks to scale up quickly.

- Continuous processes: pushing mix nonstop for steady high-volume output.

Laboratories still need small, quiet mixers during early product tests, so the same basic tank design serves all sizes.

Why Pick Our Tanks?

- High Efficiency: built-in gauges and motors let engineers size each unit for recovery, keeping delivery speeds high.

- Long-Lasting Durability: every tank uses 316L or 304 stainless steel sealed with argon for daily scratches and hot-cold cycles.

- Optimized for Pharmaceutical Standards: laser-clean welds and CIP extras mean each lot meets the strict audits every plant fears most.

- Wide Voltage Power Flexibility: tanks run on grids from 110V wall plugs to 600V mains, with ranges from 1.5KW lab tests to 55KW bulk runs.

Ready to Buy or Tweak It Just for You?

We get that every drug-making plant has its own way of doing things. Because of that, our mixing tanks come in different sizes, materials, power ratings, and voltages. If you want a tank that fits your line perfectly, reach out, and we’ll walk you through the options.

Don’t settle for second best—upgrade your mixing setup with a dependable tank that meets industry standards.

Frequently Asked Questions (FAQs)

Q1: What is the lead time for custom mixing tanks?

A1: How long it takes depends on what you order. Usually, you can expect 4–6 weeks for custom-builds; off-the-shelf models ship much faster.

Q2: Can the mixing tank be used for both small and large-scale production?

A2: Absolutely! We can size the tank for tiny lab batches or for huge floor runs.

Q3: How do I choose the right material for my mixing tank?

A3: For sensitive or aggressive ingredients, 316L stainless steel is the way to go. If the formula is milder, 304 stainless steel works just fine.

Q4: Are the mixing tanks easy to clean?

A4: Yep, our tanks have slick, polished surfaces that make cleanup quick, so you spend less time between batches and keep things moving.

Q5: What power options do you offer?

A5: Power ranges from 1.5KW up to 55KW, giving you the flexibility to pick what suits your production line best.