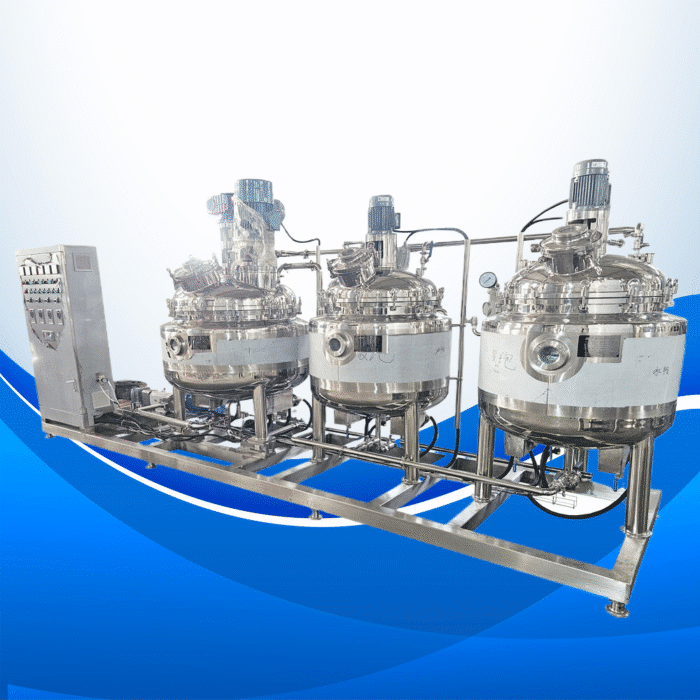

High-Quality Mixing Tank with Stirrer

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,700.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Product Overview: Mixing Tank with Stirrer

A mixing tank with attachable stirrer is a must-have in many factories, from bakeries to drug-makers and even cosmetic labs. Whether you’re blending liquids, dusty powders, or thicker pastes, this unit is built to give even mixing every single time, so you know the quality is spot-on from batch to batch.

Plug it in, set your speed, and let the tank do the hard work while you focus on the next step.

Key Features & Perks

Custom Voltage Specs:

With voltage choices from 110V home-style outlets all the way up to 600V industrial lines, the tank plugs straight into whatever set-up you already have. You don’t need to rewire your shop; just pick the model that matches your site and watch it work like it was always there.

Power When You Need It:

Pick a motor from 1.5 kW small-batch power to 55 kW heavy-duty muscle, so the stirrer never runs too fast or too slow for your mix. That way, you save energy on tiny runs yet still crank out the speed for grander orders, keeping costs in line and quality high no matter the order size.

Durable, Corrosion-Resistant Materials:

You can pick between two tough materials when you order your tank: 316L stainless steel, which fights rust even better, or budget-friendly 304 stainless steel that still stands up to heavy use. Either choice works great for everything from harsh chemicals to food-safe ingredients.

Efficient Mixing with Stirring Mechanism:

How the stirrer is built really matters if you want the mix to be even from top to bottom. Our tank comes with a strong, smooth-running paddle that pulls everything together, so there are no lumps or pockets of unmixed stuff. It handles emulsifying, blending, dissolving, and suspending ingredients in record time.

Versatile Applications:

Our mixing tank with stirrer fits right in at companies large and small, no matter the field:

- Food and Beverage: Combine sauces, dressings, soups, or drinks without recipe loss.

- Pharmaceuticals: Blend powders and liquid medicines, keeping every batch on label.

- Chemicals: Tackle thick epoxy, resin, paint, or coating formulas with zero fallout.

- Cosmetics: Turn rough raw inputs into smooth creams, lotions, and serums fast.

- Wastewater Treatment: Quickly add chemicals to huge tanks and keep flow steady through every drop.

Specs That Matter

You can pick either 316L or 304 stainless steel for the tank. It runs on voltages from 110V all the way to 600V and comes in power ratings between 1.5KW and 55KW. Tank size is whatever you need-small 50-liter units for testing or giant industrial tanks that hold over 10,000 liters.

For mixing, choose from anchor, propeller, paddle, or other stirrer styles so the blades fit your materials. The unit can be round, vertical, or horizontal, and extras like heating, insulation, or jacketed walls are easy to add.

How Customers Actually Use It

Picture a chemical plant blending safe, stable batches with a tank and stirrer that never misses a beat. In pharma, researchers use the same setup to evenly combine active ingredients before filling bottles. Food makers lean on it for sauces, seasoning each drop the same way, batch after batch.

Because the stirrer breaks lumps and moves every particle, finished products come out smooth and ready to ship. The tanks also run nonstop, cutting waiting times, boosting output, and keeping the whole line humming along.

Why Pick Our Mixing Tank with Built-In Stirrer?

Custom Fit:

Every plant runs its own way, so we let you tweak size, ports, and controls until the tank fits your line perfectly.

Rough-Ready:

Made from top-grade stainless steel, the tank laughs at spills, heat, and busy days, so you spend less time fixing and more time making.

Smart Mixing:

The stirrer design uses less power than you’d think, yet still gives a uniform blend, trimming your electric bill without skimping on quality.

Simple Care:

Wide openings and sturdy parts mean wipes, quick checks, and the occasional gasket swap take minutes, freeing you to run the line.

Take the Next Step

Want smoother, faster mixing? Order your tank with stirrer now and feel the upgrade on the very first batch. We have off-the-shelf models ready or we can build a one-of-a-kind version just for you. Whether you’re adding capacity or fine-tuning an existing line, our tanks grow right along with your business.

Get in touch today to ask for a quote, talk about the special features you want, or simply place your order. Don’t touch that mouse—make your production easier with a solid mixing tank that stirs itself!

Frequently Asked Questions

1. Can I pick the size of the mixing tank?

Totally. We build tanks in all sizes so they fit both small bakeries and big factories. Whether you need a 50-liter bucket or a 10,000-liter beast we’ve got you covered.

2. What material should I pick for my mixing tank?

If you care about rust or must follow strict health rules, go with 316L stainless. For most other jobs 304 stainless saves money without losing quality.

3. How do I know how much power my tank needs?

Power depends on how thick the mix is and how big the tank is. Super-thick materials usually need more than 5 kW. Just tell us your recipe and we’ll size the motor right.

4. Can I change the stirrer speed while it runs?

Yes, the tank’s speed control lets you speed up or slow down the mix while the job is on. Adjust the stir as your material changes, so every batch is just right.

5. Do you ship outside the U.S.?

Yep, we ship orders almost anywhere in the world. Just pick the country at checkout, and we’ll make sure your package gets to you fast and in one piece.