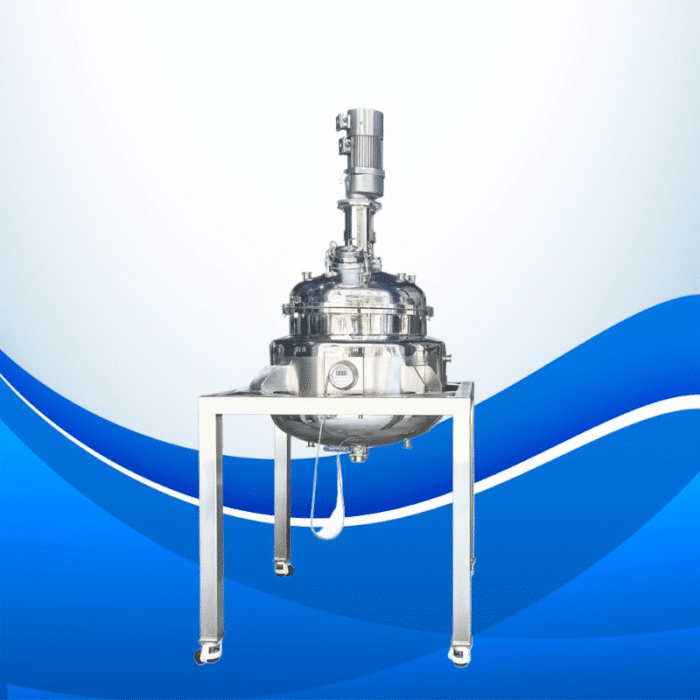

High-Performance SS Reactor for Industrial Processing

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,780.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Stainless Steel Reactor (SS Reactor) — Built for Precision, Power, and Long Life

When you need a piece of equipment that always delivers speed, exactness, and cleanliness, a top-notch stainless steel reactor (SS reactor for short) is what you want at the heart of your process. Designed to handle the toughest requirements across a range of sectors, our SS reactors come in sizes you can pick yourself, starting at 50L and going all the way to 30,000L. You can also choose the motor from 1.5KW to 11KW, so you can match the power to the thickness of what you’re mixing.

Why Go with Our SS Reactor?

Great Materials

You can pick between SS304 and SS316L stainless steel. Both resist rust like a champ, but if you’re in pharma or food where every tiny speck of dirt matters, 316L is the way to go because it’s a step ahead in keeping everything clean.

Tailored Power and Size

From a small lab bench to a giant production floor, we have a motor to match, starting at 1.5KW and peaking at 11KW so you can stir, blend, or emulsify—even with really thick liquids. Pick a tank that fits your needs between 50 liters and 30,000 liters, and it will work for you whether you run batches or a nonstop line.

Industrial-Grade Reliability

Built to keep running smoothly no matter the heat or pressure swings, our reactors come with hefty agitators, beefed-up jackets for temp control, and top-notch seals to keep leaks and contamination out for good.

Where You’ll Find Our SS Reactors

Pharma Manufacturing

Perfect for making active ingredients, mixing final products, and recovering solvents. The stainless steel stays neutral, so everything stays pure.

Chemical Processing

Great for polymerization, neutralization, and any reaction that needs tight temp and pressure control.

Food and Beverage

Whether you’re mixing syrups or fermenting, the clean design meets safety rules and keeps everything safe to drink.

Cosmetics and Personal Care

Ideal for lotions, creams, and any emulsion where the texture and blend have to stay just right.

Biotech and Lab Research

Built for pilot runs, culturing microbes, and prepping media in the lab.

Picture Real-World Use

Picture a mid-sized cosmetics plant running a 1,000-liter 316L SS reactor to whip up a new skin cream line. The variable-speed agitator dialed in for a smooth blend, and the jacket lets the team keep the right temp, so every batch comes out perfect, every time.

Imagine a sizable chemical plant running a 20,000-liter 304 stainless-steel reactor powered by an 11-kilowatt motor for nonstop polymer production. Its rugged stainless build and corrosion-proof lining keep production flowing smoothly and cut back on the downtime and repairs.

How We Can Change It Up

- Material Choices: SS304 or SS316L

- Size Choices: 50 liters to 30,000 liters

- Motor Choices: 1.5 kilowatts to 11 kilowatts

- Extras: Heating and cooling jackets, pressure and vacuum options, variable-speed control, and clean-in-place or sterilize-in-place systems.

Why Customers Keep Coming Back

- Stays strong over the long haul, even in tough chemicals

- Custom-built to match your exact setup and needs

- Fair prices plus solid technical help

- Fast shipping and setup help, no matter where you are in the world

Questions We Hear a Lot

Q1: What’s the difference between SS304 and SS316L?

A: SS316L has better corrosion resistance, so it’s a better fit for food and pharma uses.

Q2: Can the reactor manage thick, high-viscosity liquids?

A: Sure! The 11-kilowatt motor gives it the strength to handle a wide viscosity range.

Q3: Will you ship and help install it overseas?

A: Yes, we ship around the world and can send a team for install and training, if you need it.

Looking to Boost Your Production Line?

An SS reactor isn’t just a tank—it’s a smart investment that pays off in better quality, faster output, and meeting all those tough regulations. Shoot us a message and we’ll put together a custom quote that fits your capacity and what you actually make. Your best industrial performance is just a click away.