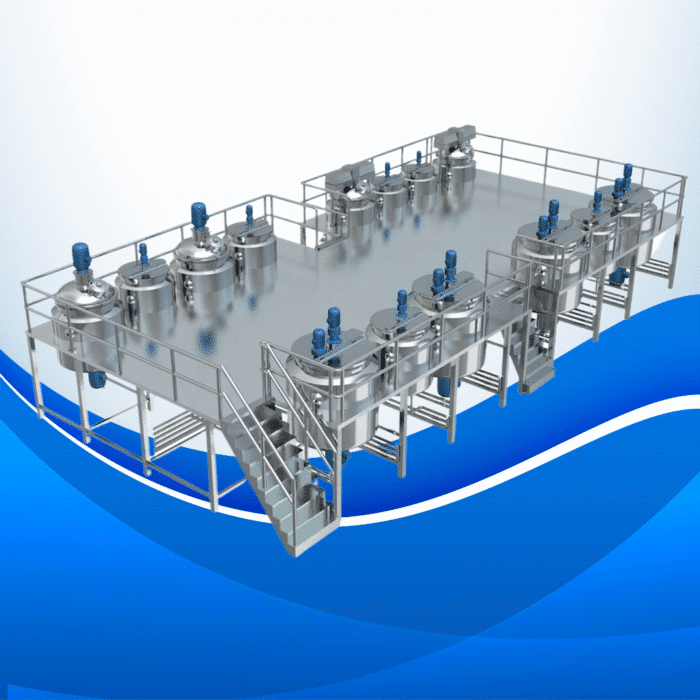

High-Performance Resin Mixing Machines

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$6,310.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Precision and Power: Your Resin Mixer Hero

When you’re deep into industrial resin work, you want a mixer that never lets you down. Our resin mixing machine is tough enough for the biggest manufacturing challenges and still serves up the same smooth, even mix every time. Plus, you can dial it in to match your exact production needs.

From coatings to adhesives, electronics to automotive, or composites, this system gives you the uniform mix that performers demand. It’s made to crank out medium to large production runs, so it’s the smart choice for anyone who can’t waste time, materials, or margin—plus it guarantees that the next batch matches the last one, batch after batch.

Applications That Keep Your Production Line Rolling

Pouring floors or layering up custom electronics? The resin mixing machine is ready:

- Epoxy Mixing: Delivers a steady mix for coatings, embeds, and insulation layers.

- Polyurethane Blends: Perfect for foams, tough adhesives, and slick automotive interiors.

- Composite Processing: Smoothly manages carbon fiber and fiberglass reinforcement every time.

- 3D Printing Prep: Serves up bubble-free resin that lays down perfectly for even the finest prints.

You’ll spot these mixers in high-output factories, R&D labs, and custom production lines where control is a must, not a nice-to-have.

Why Pick Our Resin Mixer?

- ✅ Perfect Sizes: We’ve got options from 50 liters all the way to 30,000 liters, so you choose the size that fits your batch and your operation best.

- ✅ Tough Materials: Made from 304 or 316L stainless steel, so it laughs at rust, chemicals and heat and keeps on going.

- ✅ Power to Match: Select a motor from 1.5KW to 11KW to fit whatever resin you’re mixing, whether it’s thin and slick or heavy and sticky.

- ✅ Smart Mixing Blades: Designed to trap fewer bubbles and blend every drop, so your mix comes out flawless every single time.

- ✅ Totally Sealed: Keeps the junk out and lets you mix under vacuum or pressure when you need that extra edge.

Whether you’re working with basic resin or finicky formulas, these adaptable setups put you in the driver’s seat and give you perfect results.

User-Friendly for Smooth Workflows

Every machine comes with simple controls, safety features built in, and hooks up easily to your auto lines. Cleanup is fast and maintenance is low, so you wait less and work more. Digital displays, programmable timers and adjustable mixing cycles mean you’ll always meet your exact specs.

Level Up Your Resin Game

When you need resin that’s mixed just right every single time, these pro mixers make a big difference. If you’re cranking up the volume or just want every batch to be spot-on, our machines tackle both batch and continuous mixing. You’ll save time, you’ll save energy, and you’ll save yourself a lot of headaches.

Order Today

Choosing the right resin mixer isn’t just another box to check; it’s a smart move that keeps your whole production line running the way you want for the long haul. Hit us up, and we’ll chat about what your project really needs, draft a tailor-made quote, and connect you with our tech team for the best advice you can get.

FAQs

Q1: Should I go for 304 or 316L stainless steel?

A1: 304 stainless steel works for the majority of resin jobs. Grab 316L if you’re working with really corrosive stuff or if your project needs a super-clean environment.

Q2: How do I know the motor power I need?

A2: It all hinges on how thick the resin is and how big your batch is. For thinner liquids, a motor in the 1.5KW to 4KW range will usually handle it. If you’re mixing thick stuff or big tanks, bump it up to 7.5KW or 11KW.

Q3: Can I run the mixer under vacuum or pressure?

A3: Absolutely. We have option seals that let you mix under vacuum or pressure without a hitch.

Q4: What’s the turnaround time?

A4: Normally it’s 3 to 5 weeks, but if you pile on custom requests, the schedule can slide. Just shoot us a message for the freshest delivery info.