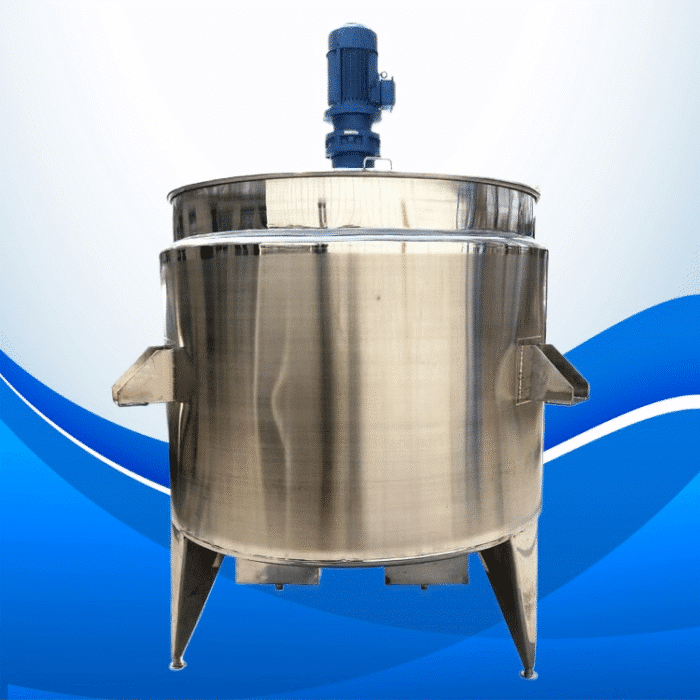

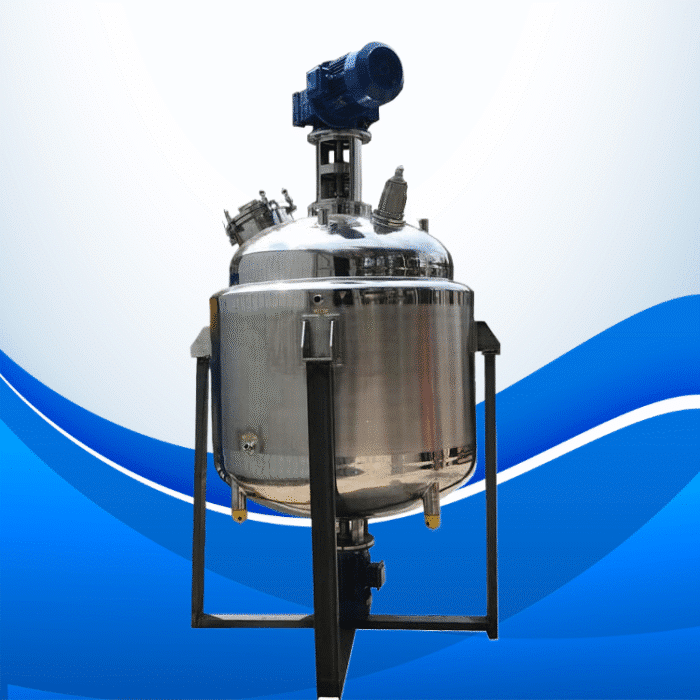

High-Performance Reactor Vessels for Industrial Processing

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$5,600.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Premium Reactor Vessels for Industrial-Scale Processing

Getting the right reactor vessel is a big deal if you need precision, reliability, and top-notch performance in your production line. Our reactor vessels are built for tough modern production floors, giving you the flexibility and strength needed for chemicals, pharmaceuticals, food, and cosmetics.

Why Pick Our Reactor Vessels?

Whether you’re ramping up output or fine-tuning batch-to-batch consistency, our vessels are designed to perform:

Material Options

Choose between 304 or 316L stainless steel—they’re both tough against corrosion, easy to sanitize, and meet strict hygiene rules.

Customizable Agitation

Agitation power can be set between 1.5KW and 11KW, letting you fine-tune mixing and heat transfer to fit your recipe.

Flexible Sizes

We offer everything from compact 50L vessels for pilot runs up to 30,000L units for full production, so you can start small and scale confidently.

Every reactor stands up to high pressure and temperature, making it perfect for demanding tasks like chemical reactions, polymerization, fermentation, or crystallization.

Common Use Cases Across Industries

We see our vessels in just about every sector and performance setting:

Chemical Manufacturing

Blend reagents, manage heat, and synthesize new compounds with total process control.

Pharma & Biotech

We help you do sterile fermentation and processing under GMP rules for APIs, vaccines, and enzymes.

Food & Beverage

Sanitary homogenization for sauces, syrups, and emulsions.

Cosmetics & Personal Care

Emulsion control for creams, gels, and lotions, keeping temperature-sensitive ingredients intact.

Every reactor comes ready to slip right into your current line, plus you can add thermal jackets, different pressure ratings, and full automation if you want.

Key Specs

| Feature | Specification Range |

|---|---|

| Material | SS 304 / SS 316L |

| Volume | 50L to 30,000L |

| Agitator Power | 1.5KW to 11KW |

| Temperature Range | Made to fit your process |

| Pressure | 1 atm to high-pressure |

| Certifications | CE, ISO, ASME (Optional) |

Think About the Day-to-Day Gains

Feel the difference when reaction times shrink, quality stays the same batch after batch, and shutdowns are shorter. Our reactors are built for the long haul and can grow with you, so adding a new module or upgrading a feature is quick and easy.

Want to Move Up?

Choose a reactor that fits your next big target. Reach out to our sales team for a quote or a technical chat, and we’ll get you fast lead times and worldwide shipping.

Frequently Asked Questions

Q: What’s the real difference between 304 and 316L stainless steel?

A: 316L has added molybdenum. That’s why it fights rust better, especially in saltwater or acidic places.

Q: Can you tweak the vessel to fit my process?

A: For sure! We can change agitators, pressure ratings, and even set up the automation to match what you need.

Q: Which certifications do your reactor vessels have?

A: Depending on where you are and what you’re doing, we can provide reactors that meet CE, ISO, and ASME standards.