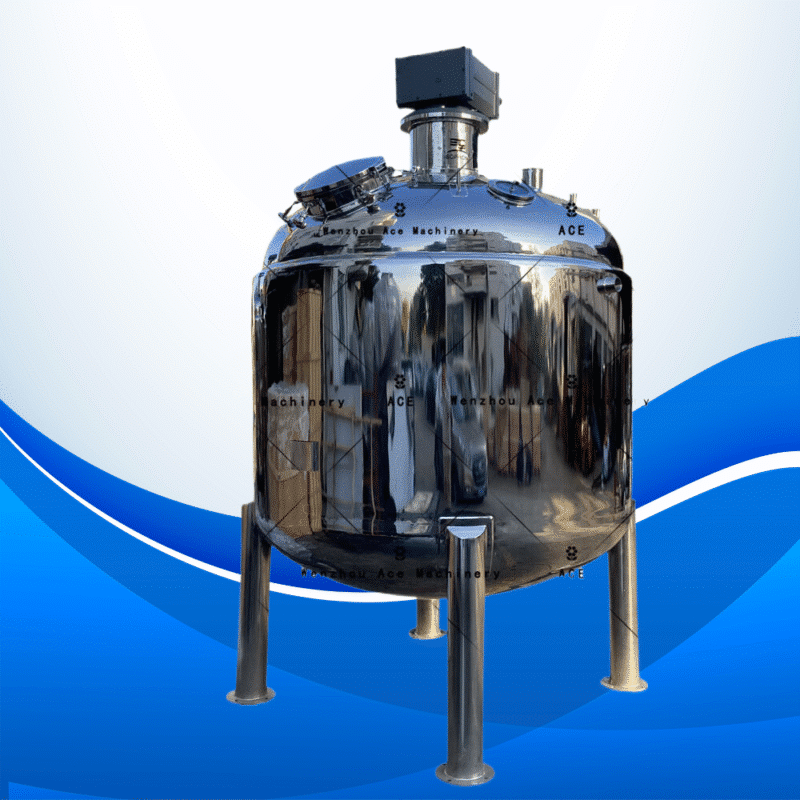

High-Performance Mixing Tank with Agitator

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,170.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

A Mixing Tank with Agitator is a must-have for any shop or plant that needs to blend liquids or soft solids with speed and precision. From drug-makers and bakery lines to chemical plants and beauty product labs, this industrial mixer is built to keep batches uniform and keep production flowing smoothly day after day.

Key Advantages:

Efficient Mixing & Homogenization

The strong paddle inside the drum spins fast or slow, moving every particle until nothing settles. Whether you are dissolving powder, folding in thick pastes, or making a stable cream, adjustable speeds and swap-out blades give lab-level repeatability at bigger volumes.

Customization Options

Every workspace is different, so we offer tanks in any input voltage, from 110V outlets to 600V three-phase feeds. Power ratings from 1.5KW pilot-size units to 55KW heavy haulers mean you get just the punch you need, letting small R&D labs and high-speed factories use the same dependable design.

Tough, Rust-Resistant Materials

Pick between 316L or 304 stainless steel for your build. Choose 316L when you really need to fight rust, like in pharma plants or food lines. For less harsh spots, 304 still gives you long life without breaking the bank.

Safer, Longer-Lasting Design

Our agitator and tank are built to take a beating, so you spend less time fixing them. Solid seals keep leaks to a minimum and let you run the system safely for hours on end.

Works Well in Many Industries:

Pharma

Use it to mix solutions, suspensions, or emulsions with the same quality every time.

Food and Drink

Blend sauces, dressings, or soups without losing flavor or texture.

Cosmetics

Get lotions, creams, and serums blended exactly the way you want them.

Chemicals

Combine resins, polymers, or other chemicals faster and waste less material.

Technical Specs:

Voltage Choices

Plug it in at 110V, 220V, 380V, 440V, or even 600V if that suits your setup.

Power Level

Pick between 1.5KW and 55KW, tuned exactly to what your job needs.

Material

Go with 316L stainless for harsh environments or 304 stainless when you just want solid durability.

Mixing Speed

Turn the dial to match the task, from a slow blend to a fast whip.

Tank Size

From tiny lab vessels to big factory drums, we’ll build the tank to the size you ask for.

Blade Style

Choose props, turbines, paddles, or other blades, so you get the mix you expect every time.

Temp Range

Tough enough for chilly freezers or hot cooking lines without skipping a beat.

Application Scenarios:

Think about a drug-maker carefully combining actives with solvents for a perfect batch. Now picture a sauce plant folding oil, spices, and flavorings together to hit just the right pour-almost every food line on the planet counts on hard-working mix tanks like these. Because a dependable tank with a good agitator cuts down on wasted time, keeps workers safer, and brings every jar or drum up to the same high standard.

So whether you’re blending chemicals, whipping cake batter, or crafting lotions, this set-up speeds the whole line. It takes the grunt work off the floor, trims rejects, and hands you products that feel, smell, and look exactly the same.

Call to Action:

Want to boost your production line? Our mixing tank with built-in agitator works hard for every industry. Drop us a line for a free quote, and we’ll show you how we can tweak features and specs to fit your operation. From food and pharmaceuticals to chemicals and cosmetics, these tanks are made to deliver top performance every day.

So don’t hesitate—lift your speed and product quality with our mixing tank today!

Customization & FAQs:

Q: Can the agitator spin at different speeds?

Absolutely! We can set it up with variable speeds and blade styles to fit your recipe.

Q: Should I pick 316L or 304 stainless steel?

Go with 316L if your materials are sensitive or highly reactive; 304 works just fine for most everyday mixes and saves you some cash.

Q: Can the tank handle high-heat jobs?

Yes, it can. Just tell us the heat range, and we’ll match the seals, glass, and agitator to suit your process.

Q: What upkeep does the tank need?

A quick rinse after each batch and a look at the agitator seal every few months are all it takes to keep the system happy for years.

Upgrade your production line with our tough mixing tank that comes with a built-in agitator. Contact us now to learn more or to tweak the design so it fits your needs perfectly!