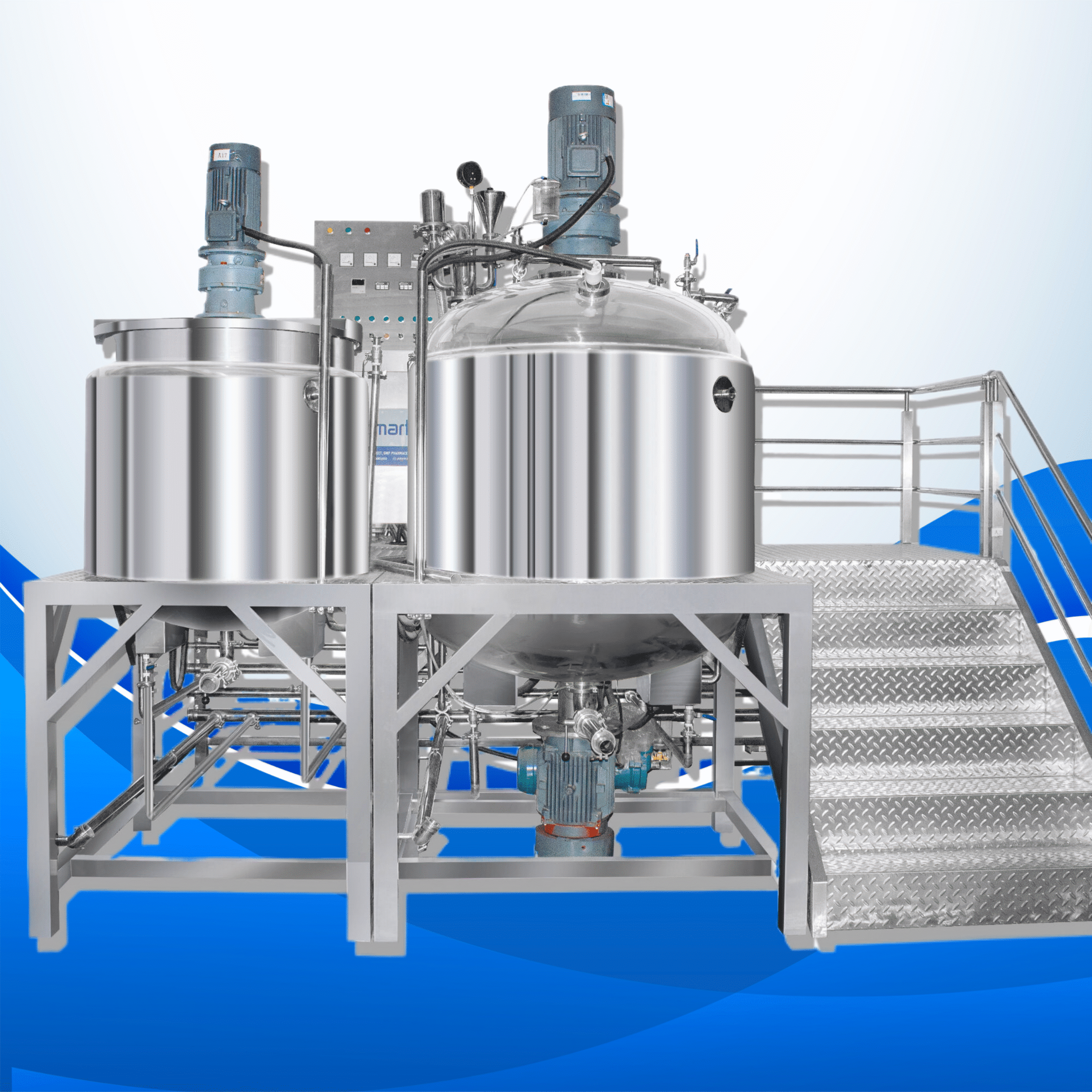

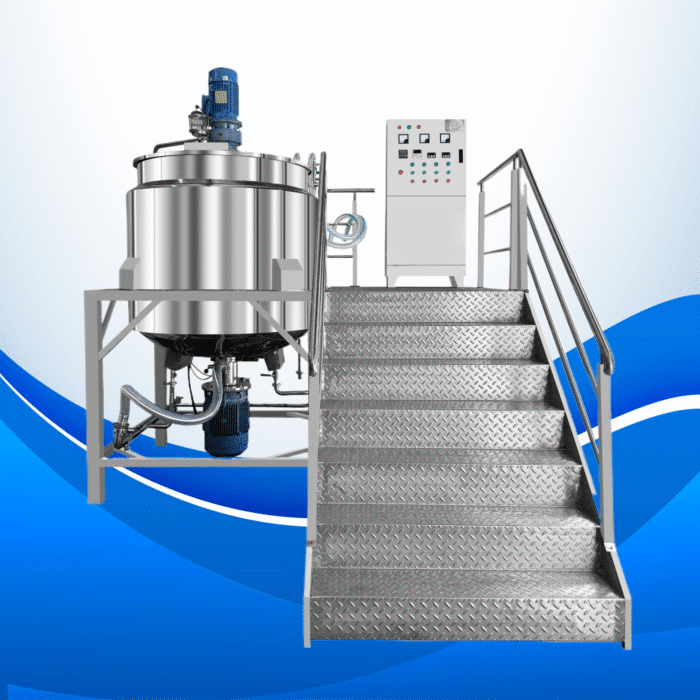

High-Performance Liquid Soap Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,200.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Liquid Soap Mixing Tank: the Perfect Partner for Smooth, Fast Soap-Making

Being good at soap making these days means being quick, tough, and steady, so every bar meets high standards. Our Liquid Soap Mixing Tank brings those qualities together in one piece of gear, helping makers blend ingredients without slowdowns or spills. Thanks to its smart power controls and sturdy build, the tank mixes raw oils, lye, and scents into a uniform batch, ready to pour within minutes. Whether the order is for everyday hand wash or a boutique lavender bar, the unit runs quietly while guarding taste, scent, and foam, batch after batch.

Cool Features and Real Perks of the Liquid Soap Mixing Tank

1. Custom Power and Voltage Options

Every workshop is wired a little differently, so we built the Liquid Soap Mixing Tank with flexible voltage and horsepower to fit yours. From 110V home setups to 600V factory lines, and from gentle 1.5KW drives up to 55KW beefy motors, you pick the setting that keeps the machine happy and bends the power bill in your favor.

Voltage Choices: 110V, 220V, 380V, 600V

Power Ratings: 1.5KW, 5KW, 10KW, 15KW, 55KW

Because of these voltage and power choices, a plant manager can drop the Liquid Soap Mixing Tank into almost any line, big or small, without extra headaches or downtime.

2. Premium Parts for Toughness and Cleanliness

The tank comes in two grades of stainless steel, 316L or 304. Both resist rust, clean up easily, and hold up over years of daily use, which is why they’re fitted into medical labs and soap plants alike.

316L Stainless Steel: Built for the tough job sites, it’s exceptionally resistant to acid, salt, and sweat. That makes it a go-to when the recipe includes aggressive ingredients that chew up lesser metals.

304 Stainless Steel: Still strong, this grade costs less while keeping rust away and speeding up routine wipe-downs.

Either choice keeps the mixer running, cuts repair delays, and protects profits, dishing out dependable performance for seasons to come.

3. Efficient Mixing and Homogenization

Our Liquid Soap Mixing Tank comes with a high-tech agitator that makes sure every ingredient blends together smoothly. Whether you’re adding essential oils, surfactants, or any other soap component, the tank keeps the mix from separating, so each batch looks and works the same. Plus, you can dial the blade speed up or down, letting you match the stir rate to how thick or thin your formula is.

4. User-Friendly Design

Built with operators in mind, the Liquid Soap Mixing Tank sports an easy-to-read control panel that almost anyone can master in minutes. Safety is a priority, so the unit has overload alarms, automatic-temperature shut-offs, and other features that keep people and equipment out of harm’s way, even in busy factories. With its roomy drum, the mixer can run big batches for hours, letting your team focus on packing, shipping, or other important work instead of hovering over the machine.

Application Scenarios: Where the Liquid Soap Mixing Tank Shines

From start-ups to regional brands, our mixer fits many soap-making settings, making it a smart pick for:

- Industrial Soap Production: Keep the lines running with hassle-free, high-volume liquid-soap batches for stores, hotels, or factories.

- Small-Batch Soap Makers: Great for artisan soap shops that need steady mixing to nail their special recipes.

- Cosmetic Manufacturers: Ideal for blending lotions, creams, and serums, so every bottle has the same smooth feel.

- Detergent Makers: Blends surfactants, scents, and other additives for clear, effective liquid soaps and cleaners.

Thanks to these uses, the Liquid Soap Mixing Tank becomes a handy, time-saving tool on any busy production line.

Technical Specifications

- Capacity: 500 to 5000 liters; we can adjust it to fit your daily output.

- Material: Pick 316L or 304-grade stainless steel.

- Voltage: Available in 110V, 220V, 380V, or 600V.

- Power: Ranges from 1.5 KW up to 55 KW.

- Agitator Speed: Twist the dial to set from a slow crawl to 300 RPM.

- Temperature Control: Built-in sensors keep tabs on product heat.

- Sealing: Heavy-duty seals stop leaks and keep contamination out.

Why Choose Our Liquid Soap Mixing Tank?

Our Liquid Soap Mixing Tank gives you clear perks over old-school mixers:

- Faster Mixing: A strong, smart agitator cuts blending time almost in half.

- Rock-Solid Quality: Every batch looks, smells, and works the same, batch after batch.

- Save Power: Pick the voltage and wattage your shop needs, then watch the bills drop.

- Durability: Built from high-grade stainless steel, this tank stands up to daily wear and tear, cutting down on repair bills for years.

- Customization: Choose the size, voltage, and power level you need, and we’ll make a tank that fits your exact workflow.

Ready to Order or Customize?

The Liquid Soap Mixing Tank is a workhorse for today’s busy soap plants. Whether you want a standard model off the shelf or a one-of-a-kind build, our crew guides you from idea to final delivery. We’ll chat with you, suggest the best features, and make sure the setup matches your line without headaches.

Reach out today to outline what you need and lock in your order. If adjustments are needed later, our flexible customization keeps production running smoothly.

Commonly Asked Questions (FAQs)

1. What is the maximum capacity of the Liquid Soap Mixing Tank?

Our tank can hold anywhere from 500 liters to 5000 liters, so you get exactly the volume that matches your shift plan.

2. Can I choose different power and voltage options?

Absolutely; voltages from 110 V to 600 V and power ratings between 1.5 kW and 55 kW let you align the tank with your existing system.

3. Can I use this tank to mix cosmetics instead of just soap?

Sure thing! The Liquid Soap Mixing Tank works great for soap, cosmetics, and even liquid detergent recipes.

4. How hard is it to keep the tank clean and ready to go?

It’s made from sturdy stainless steel, so it resists rust and wipes down easily. Overall, the design keeps upkeep simple and rare.

5. What if I need a tank built to my exact needs?

No problem—we provide custom setups that match your production line. Just share your ideas, and we’ll work together to create the right tank.