High-Performance Large Capacity Mixing Tank for Industrial Applications

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

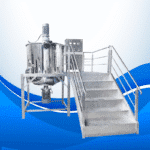

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$5,200.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Introduction to Large Capacity Mixing Tanks

A large-capacity mixing tank is a must-have for any plant that needs to blend big batches of liquid or powder quickly and evenly. Built to tackle tough jobs, these tanks fit right into chemical, food, drug, and water-treatment lines. Whether you need to mix thin liquids, dry powders, or thick sludge, the tank will deliver a uniform blend and keep your line moving.

Key Features & Advantages

High Efficiency and Reliability

These tanks are built tough, so they keep mixing day after day with very little upkeep. Even through long production runs, you can count on them to work quietly, reduce downtime, and keep quality tight.

Flexible Power and Voltage Options

No matter where in the world your line sits, you can choose a voltage from 110V up to 600V. The motor also comes in power ratings from 1.5KW to 55KW, so you get exactly the punch you need without wasting energy.

Durable Construction Materials

Choosing the right materials helps to mix tanks last longer and work tougher. We offer two premium options for our large-capacity mixing tank:

316L Stainless Steel – This grade resists rust and damage well, making it perfect for chemical and pharma work.

304 Stainless Steel – A friendlier-priced pick, it suits everyday industrial jobs where extreme corrosion protection isn’t critical.

Advanced Mixing Technology

Every tank comes with a top-notch mixing system built to tackle even rough jobs. Light liquids, heavy pastes, or thick emulsions – all blend evenly thanks to this clever design.

Customizable Design Options

Our mixing tanks are highly customizable so you can adjust tank size, speed, and extra features to fit your process. In short, you get a big tank made exactly for how you work, nothing more, nothing less.

Applications of Large Capacity Mixing Tanks

Chemical Industry

In chemical plants, even mixing protects quality and safety. Our large tanks handle chemical solutions, emulsions, and suspensions, keeping every batch consistent from start to finish.

Food and Beverage Production

A big mixing tank does more than hold ingredients; it guarantees that sauces, soups, or drinks blend evenly every time, locking in the same taste for every batch. It also powers through the tricky job of turning powdered mixes into smooth liquid bases.

Pharmaceuticals

When medicine is at stake, everything has to be precise and super clean. Built from 316L stainless steel, our tanks meet those tough rules, letting you mix compounds without worrying about rust or germs slipping in.

Water Treatment Plants

At water treatment plants, our roomy mixing tanks spread chemicals through water fast and evenly. That steady mix speeds up purification, helping teams deliver cleaner, safer drinking water to communities on time.

Cosmetics and Personal Care

In the cosmetics aisle, looks matter, but so does how products perform. These tanks join up creams, lotions, and gels so you can fine-tune texture, thickness, and shine before anything hits store shelves.

Customizable Specifications

Material Options:

- 316L Stainless Steel: Top choice for harsh or sterile jobs, from pharma labs to seaside plants.

- 304 Stainless Steel: Friendlier on the budget, while still tough enough for everyday work.

Voltage Options:

Pick from 110V, 220V, 380V, 440V, or 600V to match power supplies around the world.

Power Options:

Pick anything from 1.5 kW to 55 kW, so you get just the right punch for your production line.

Why Pick Our Big Mixing Tanks?

- Customization: Size, material, and power level are all built the way you want them.

- Rugged Build: Made from tough, corrosion-resistant stuff, so the tank works day-in and day-out.

- Speed: Tanks mix huge batches fast, saving you time and cutting energy costs.

- Flexibility: Works great in chemical plants, bakeries, breweries, and just about any other factory.

Call to Action: Order Your Custom Tank Today!

Ready to supercharge your mixing line? Our experts will help you pick the perfect setup, then build it just for you. Don’t delay — order now and enjoy reliable performance from a tank made to your specs. We even offer one-off designs if the standard options don’t fit.

Common Questions

Can I pick the size of the tank?

Absolutely, each tank is built to match the volume and capacity you need.

What materials are the tanks made from?

Choose 316L stainless steel for harsh environments or 304 stainless steel for general use, whichever suits your process.

What voltage options can I choose?

You can pick any voltage between 110V and 600V, so your tank works with the power supply in your area.

What power levels do the mixing tanks offer?

The tanks come with motors from 1.5 kW up to 55 kW, so you can select the amount of energy your job needs.

How do I make sure a big mixing tank suits my plant?

Just tell us how big, what material, and what power you want, and we’ll build it that way. Contact our team for a quick and friendly chat.