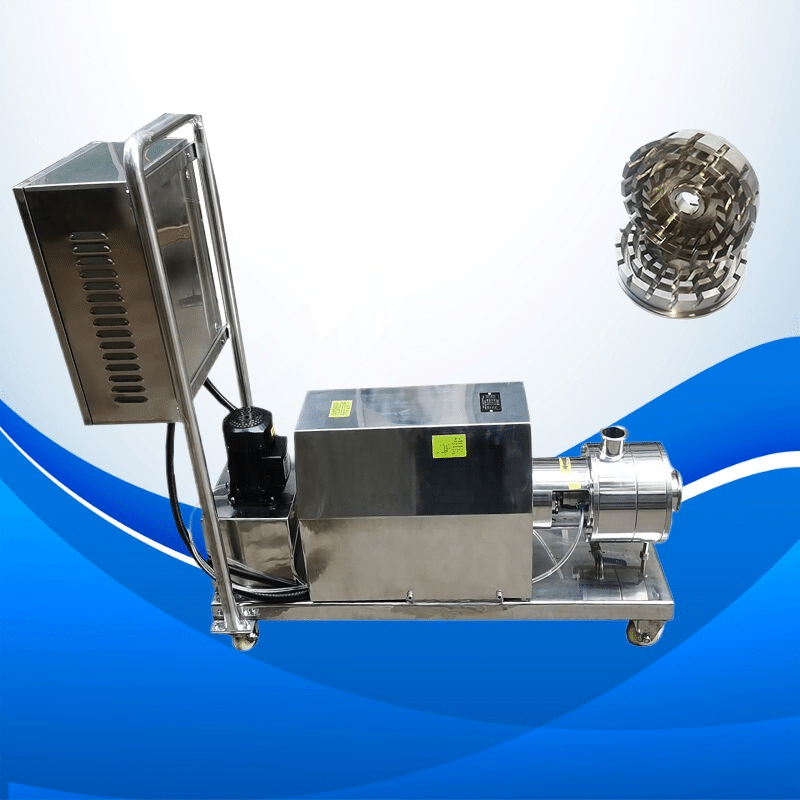

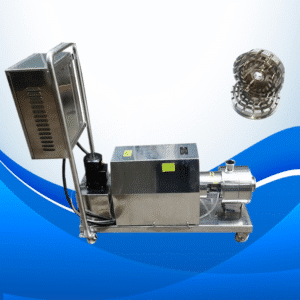

High-Performance Inline Mixer Solutions

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$2,540.00

Guaranteed Safe Checkout

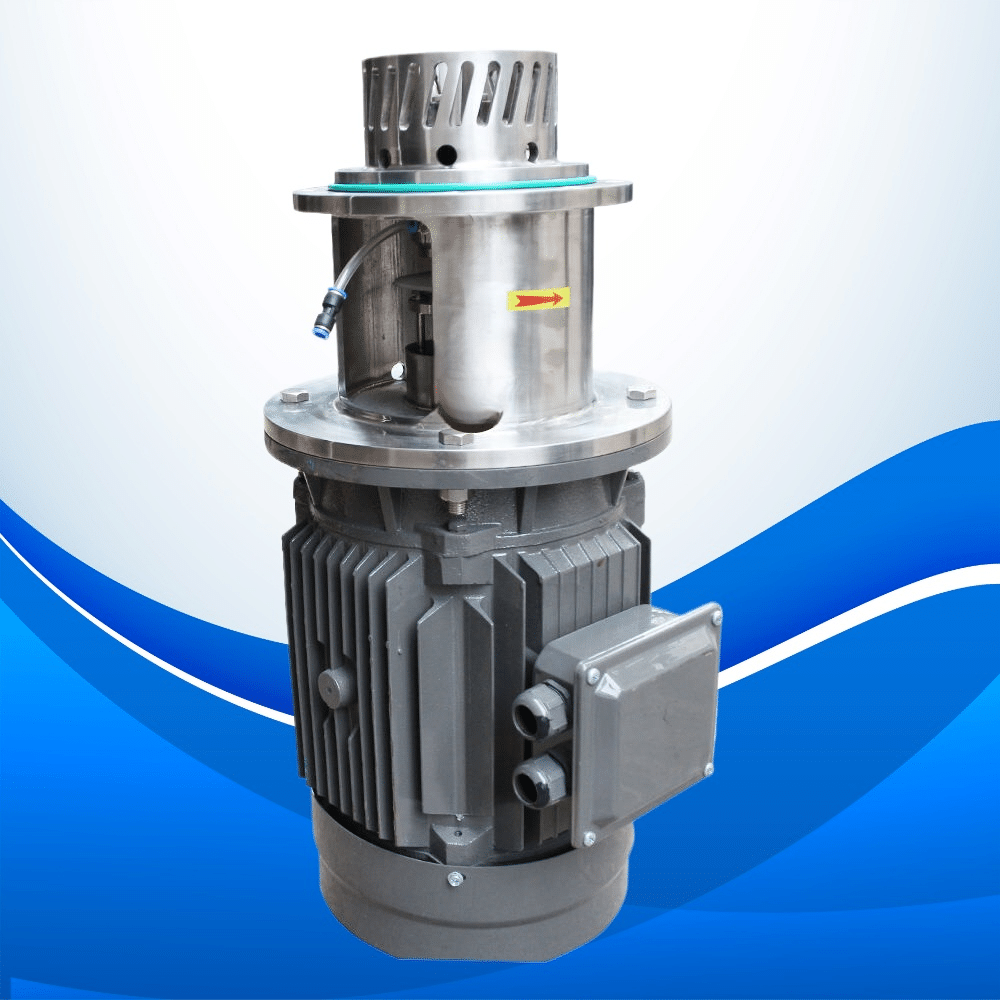

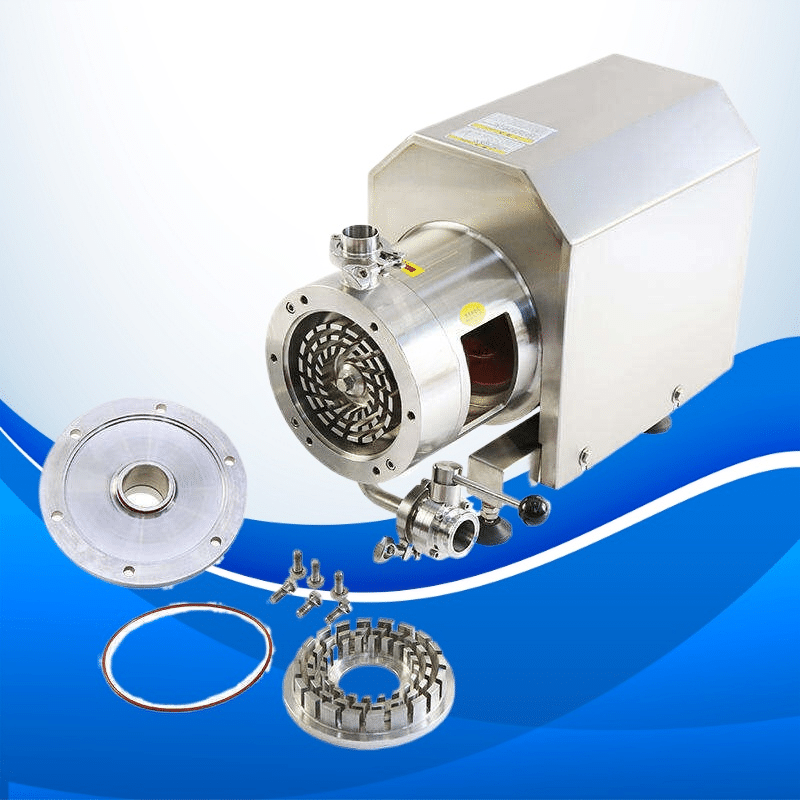

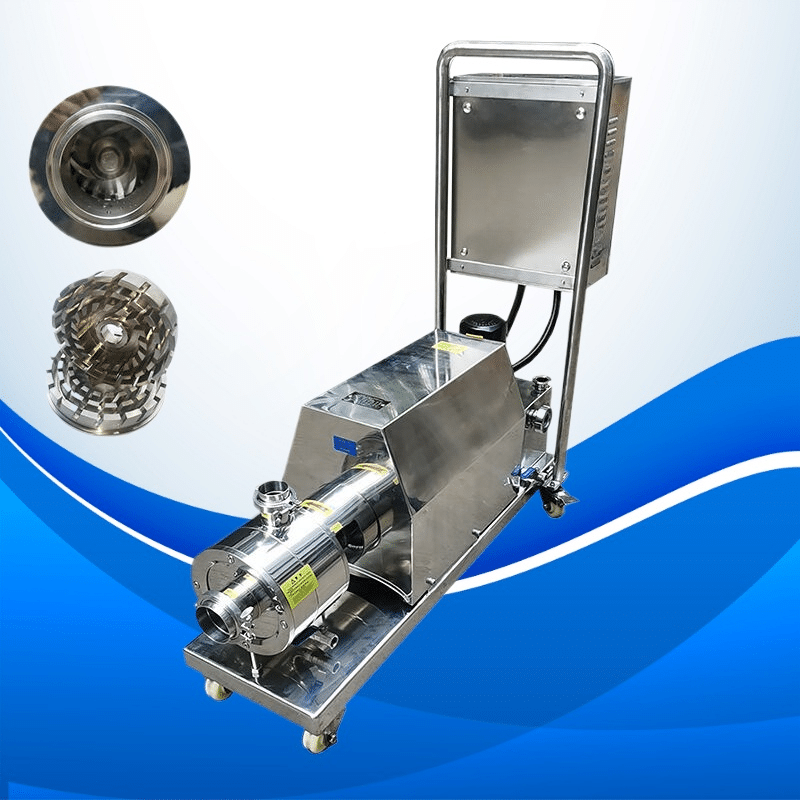

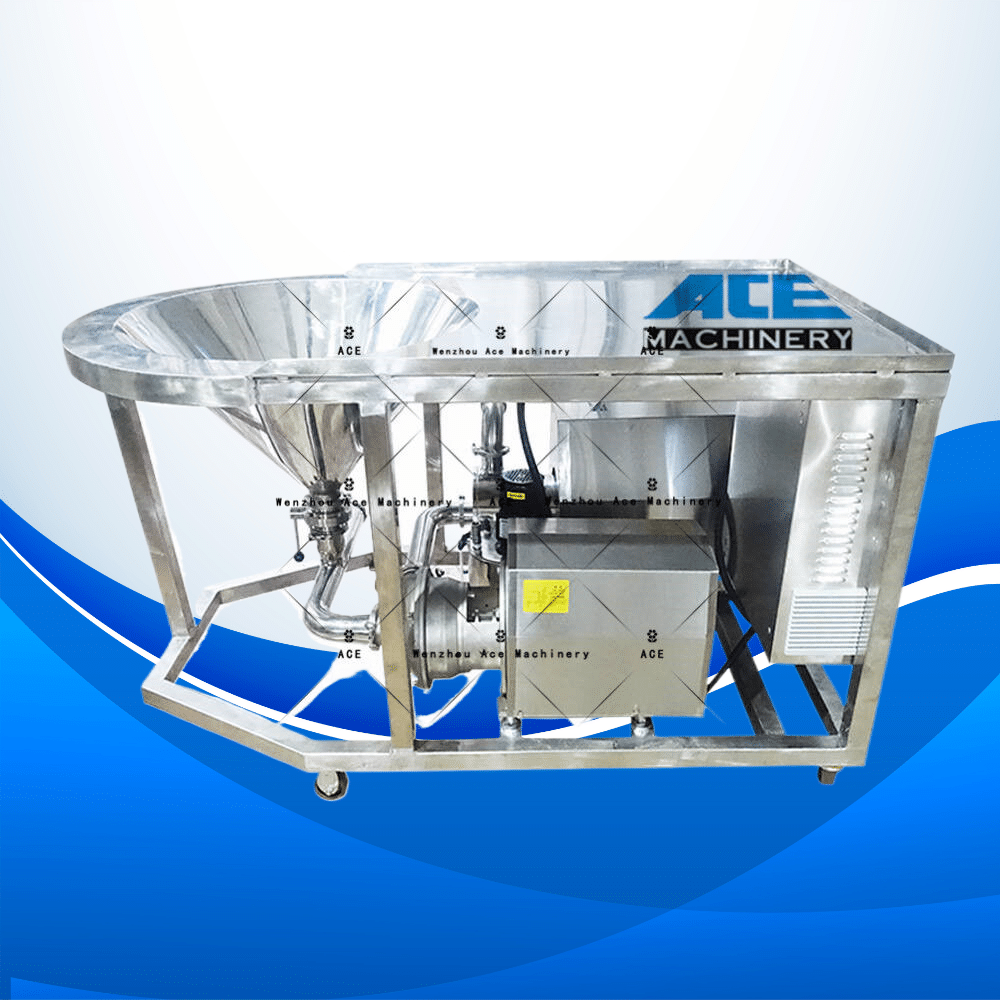

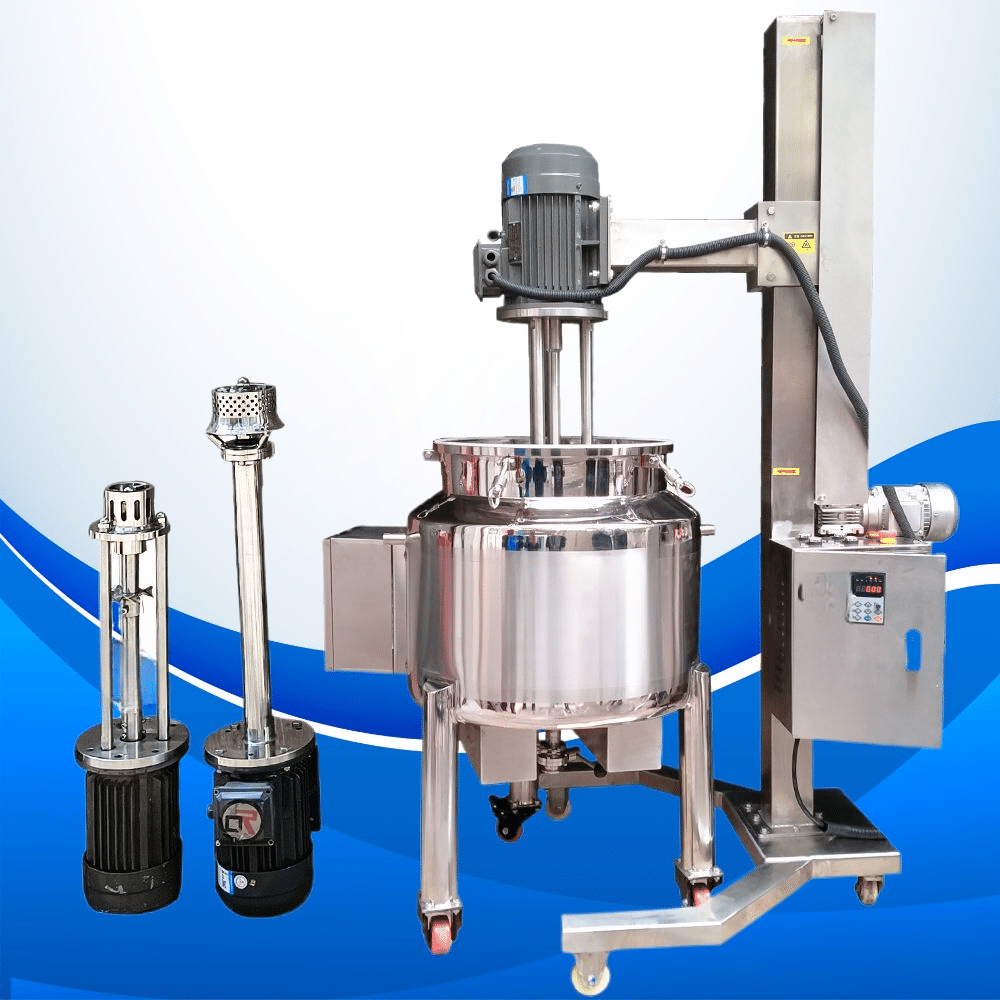

We manufacture and sell the following types of mixers

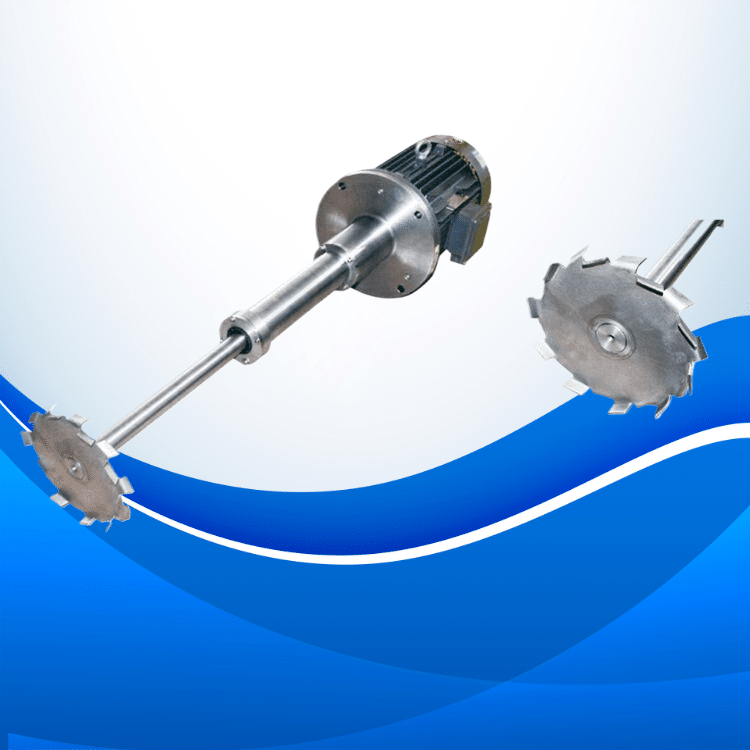

Mix, emulsify, homogenize, disintegrate and dissolve

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

Easy to move and lift

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

Give your production line a serious upgrade with our top-line inline mixer, built to slide right into any setup and mix like a pro. Made for the chemical, food, pharma, and waste-water teams, this machine churns out the same high-quality blend, shift after shift, year after year.

🔧 Key Advantages

Efficient Continuous Mixing

The mixer spreads liquids, slurries, or gases quickly and evenly. Turn a couple knobs to adjust flow and shear, and you’ll keep every batch free of dead zones or surprises.

Flexible Power & Voltage Options

Pick a voltage between 110 V and 600 V, and a power level from 1.5 kW to 35 kW, so whether you run a hobby line or a full factory, we’ve got you covered.

Premium Stainless Steel Materials

304 stainless steel comes standard, but for tough jobs you can upgrade to 316L, making it perfect for clean food rooms or harsh chemicals, whichever suits your process.

Compact & Durable Design

An inline layout cuts back on space and makes piping easier. Heavy-duty seals and tough bearings are built to take constant work in high-pressure or high-speed setups.

Easy Customization

From gentle stirring to high-shear smashing, you can choose shaft length, blade style, and flange type to fit your exact line.

🌍 Application Scenarios

Food & Beverage

Blend syrups, oils, or colorants into big batches without stopping the line. The CIP-friendly build passes even the toughest hygiene checks.

Chemical & Petrochemical

Mix solvents, acids, and bases in continuous reactors without worry—smart shear angles stop layering and keep product quality high.

Pharmaceutical Production

Homogenizes suspensions and emulsions inline, meeting GMP requirements with sanitary 316L build and minimal dead zone design.

Wastewater Treatment

Add coagulants, flocculants, or pH adjusters directly into process streams—smaller footprint, faster mixing, and a cleaner effluent.

Cosmetics & Paints

Blend pigments, fragrances, or surfactants into thick liquids with ease. Inline setup delivers uniform texture and stable heat.

📊 Technical Specifications

| Feature | Options |

|---|---|

| Voltage | 110 V, 220 V, 380 V, 480 V, up to 600 V |

| Power | 1.5 kW • 3 kW • 5.5 kW • 7.5 kW • 11 kW • 15 kW • 22 kW • 30 kW • 35 kW |

| Materials | 304 stainless steel • 316L stainless steel |

| Shaft Speed | Up to 3,600 RPM (custom speed control available) |

| Seals & Bearings | Mechanical seals / PTFE or ceramic options |

| Inlet/Outlet Flanges | ANSI/DIN/JIS/BSP, tri-clamp (custom piping fits) |

| Temperature Range | –20 °C to +150 °C (high-temp option available) |

🛠 Why Upgrade to Our Inline Mixer?

- Quality Consistency — Running nonstop badges stop batch-to-batch wiggle, meaning steadier product and less rework.

- Space-Saving Style — Our slim mixer slides into crowded production lines, freeing up valuable floor space.

- Less Time on Repairs — Stainless steel housing and smart seals resist wear, so you spend fewer hours and dollars on maintenance.

- Safer Processes — Stronger parts and certified seals shield your blend from rust contamination.

🛒 Ready to Upgrade?

Stop putting up with uneven mixes. Order a custom inline mixer built to your voltage, power, and material specs. Get in touch today for a quick quote, and see how pro-level mixing can supercharge your line.

❓ Common Questions

Q1: Will it fit my current pipe run?

A1: For sure. Just pick your flange style-ANSI, DIN, BSP, or Tri-Clamp-and we’ll build the layout you need.

Q2: Should I pick 304 or 316L?

A2: 304 works fine for most water and mild fluids. Switch to 316L if you’re handling heavy chemicals, salt water, or pharma-grade stuff.

Q3: How do I pick the right motor voltage and power?

A3: That answer lives in your flow rate, fluid thickness, and mixing strength. Tell us those details, and we’ll match you to the best combo from 110 V-600 V and 1.5 kW-35 kW.

Q4: How much upkeep does the mixer really need?

A4: It’s built for easy care-just swap the mechanical seals and check the bearings once every 6 to 12 months. Optional tough impellers can make the machine last even longer.

Q5: Can you help with a special mixing project?

A5: Absolutely! Whether you’re blending thick lotions or gentle medicine emulsions, we can craft the right blades, set up speed controls, and add the clean fittings you need.