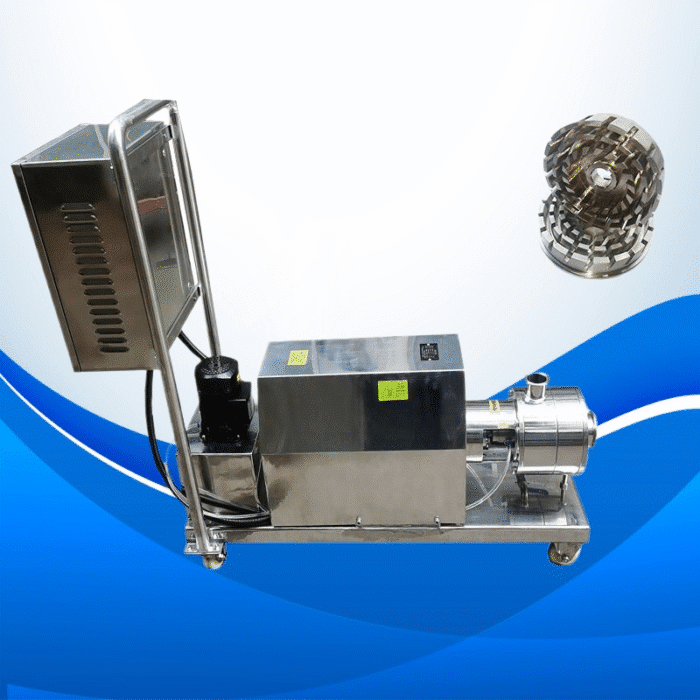

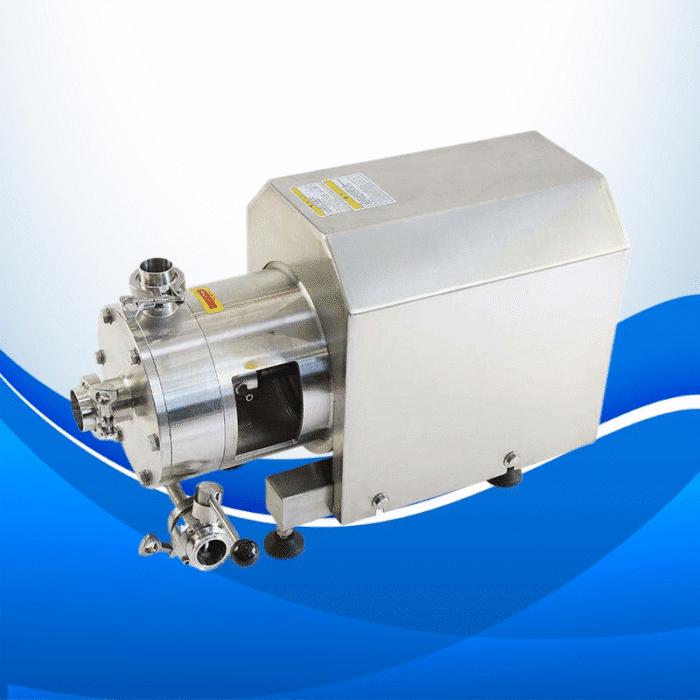

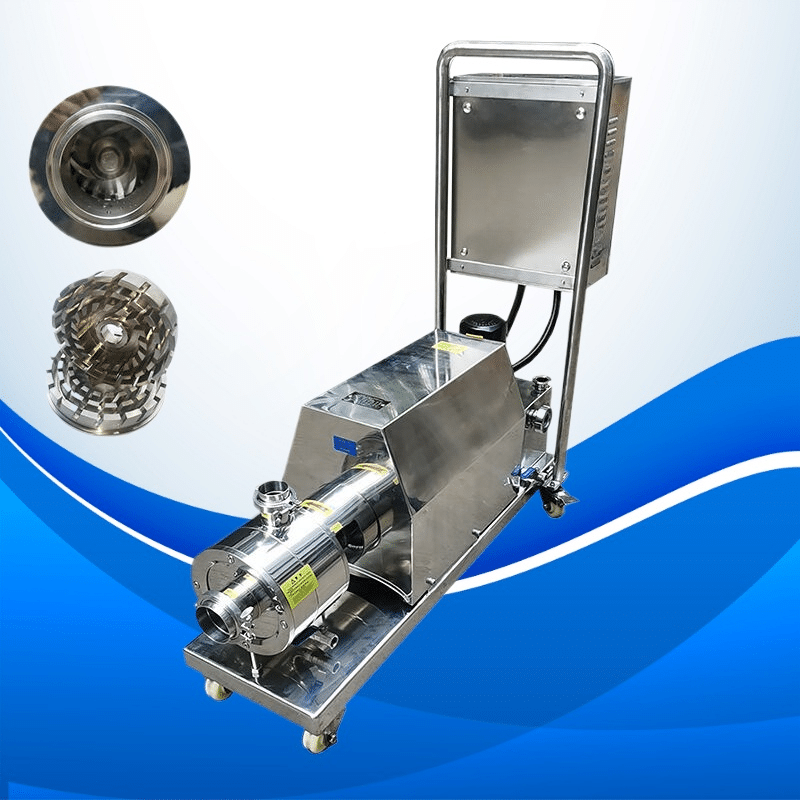

High-Performance Inline Mixer Pump for Precision Blending

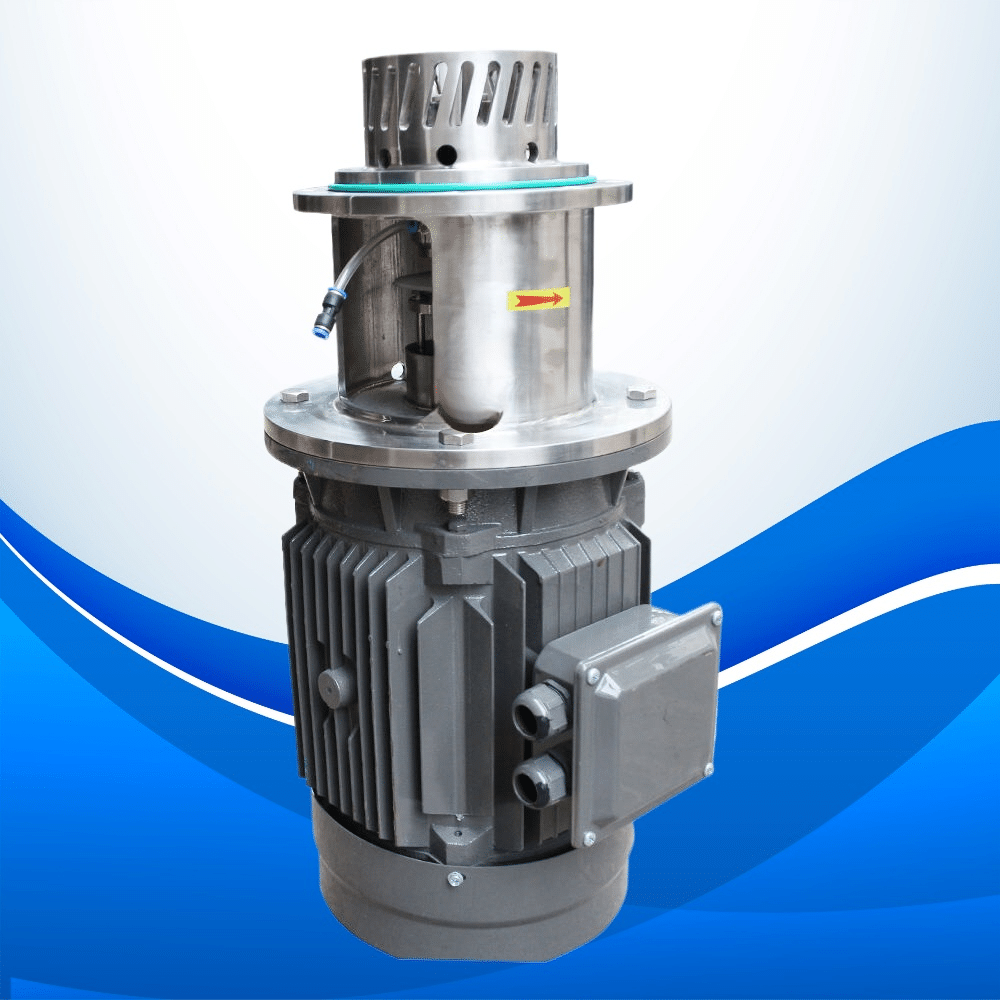

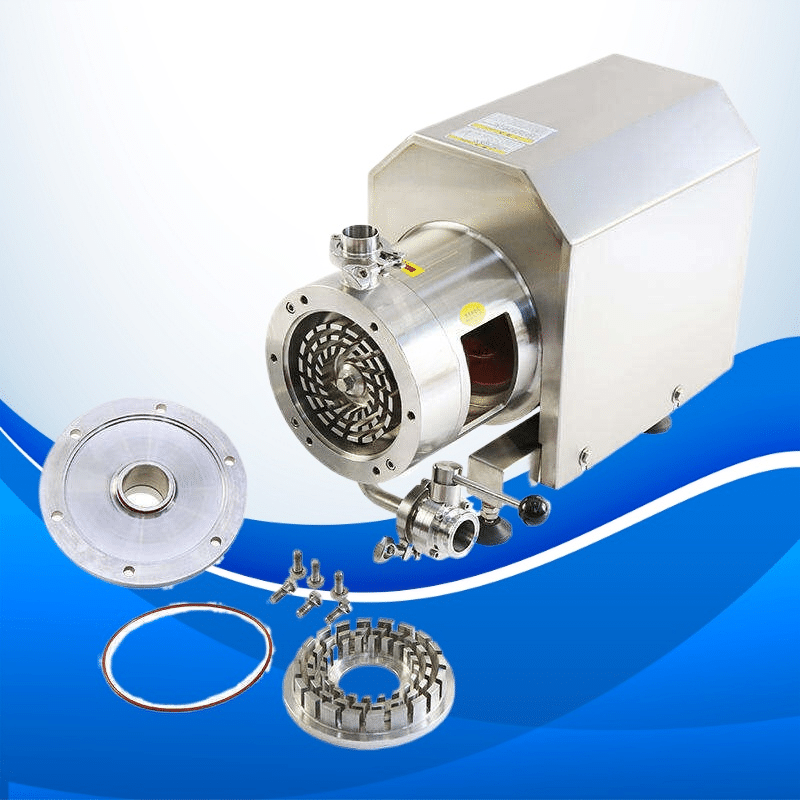

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$2,300.00

Guaranteed Safe Checkout

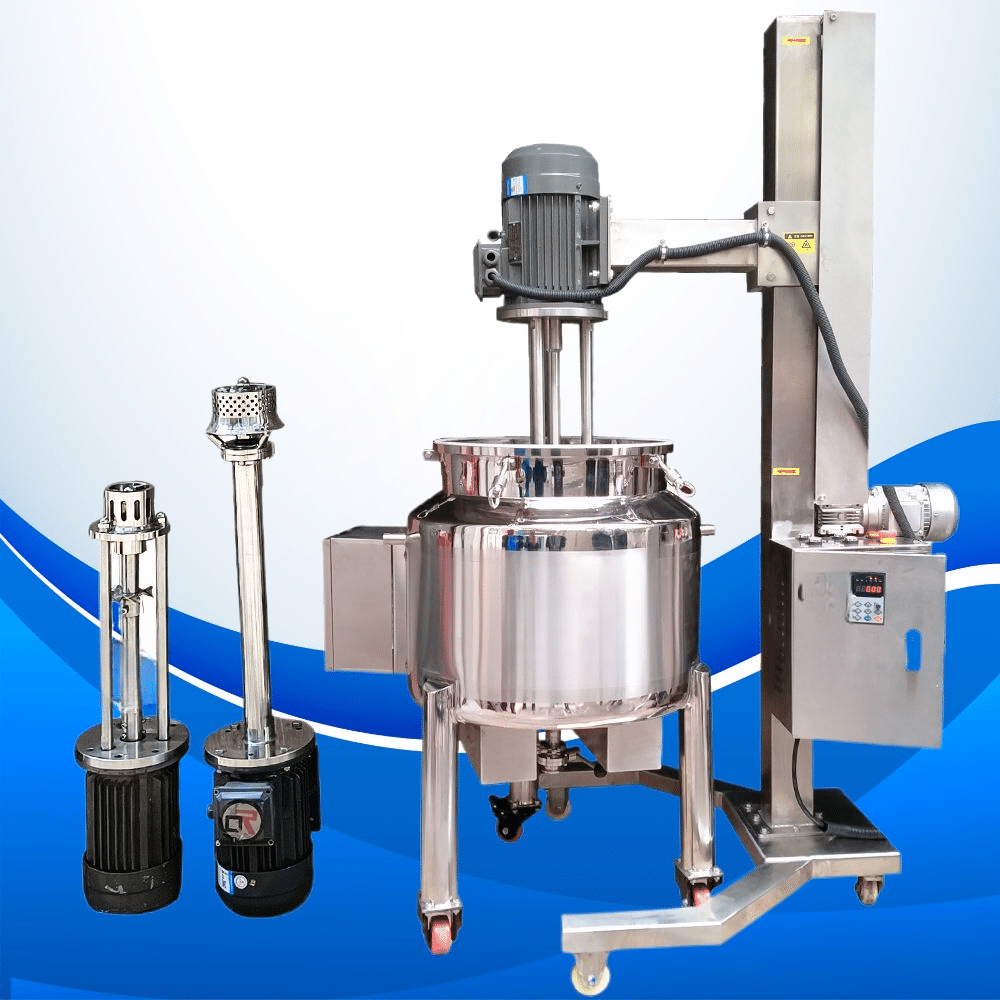

We manufacture and sell the following types of mixers

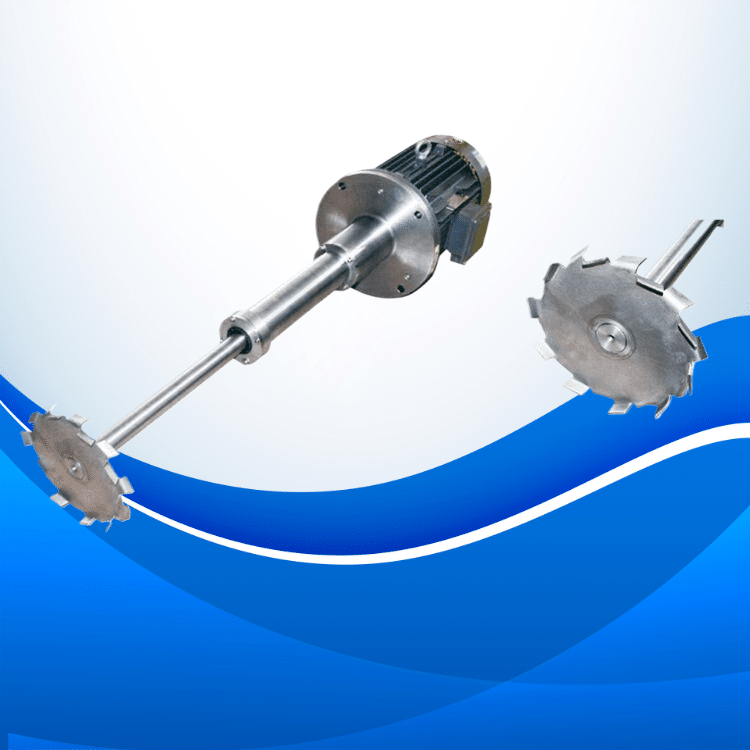

Mix, emulsify, homogenize, disintegrate and dissolve

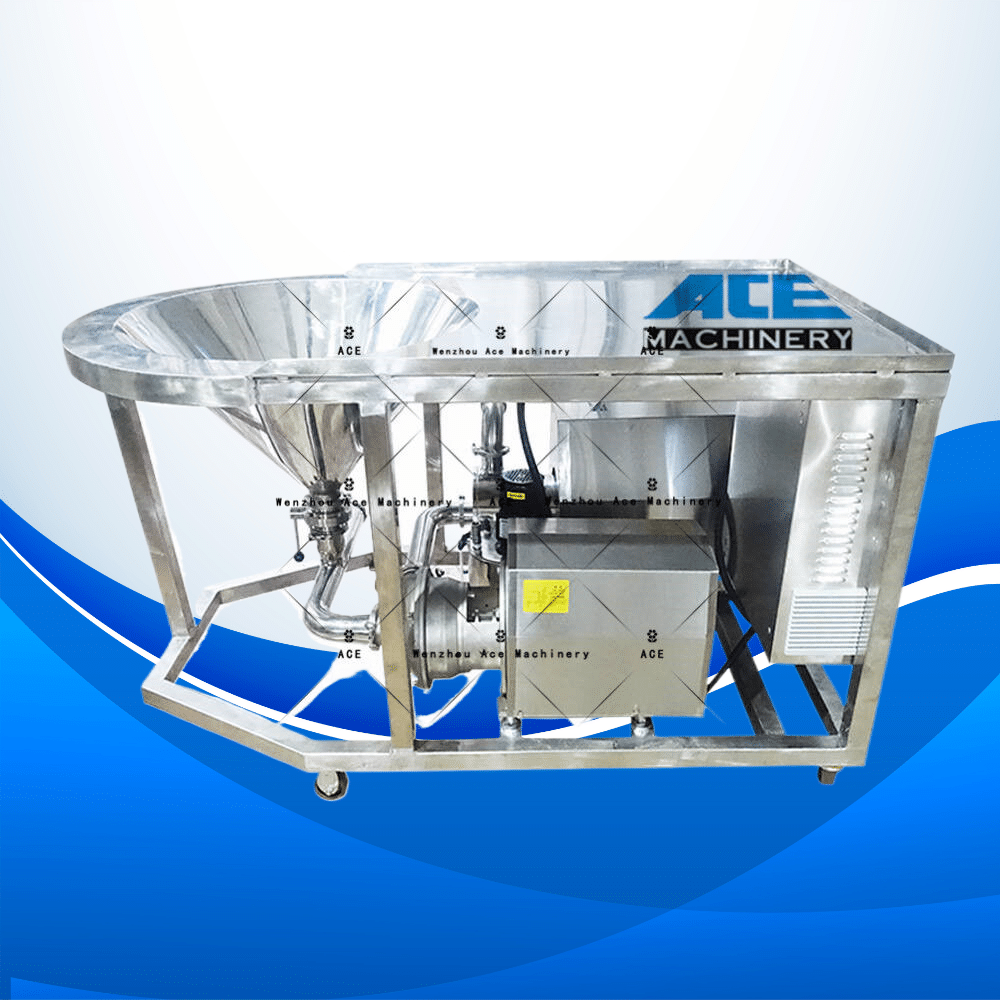

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

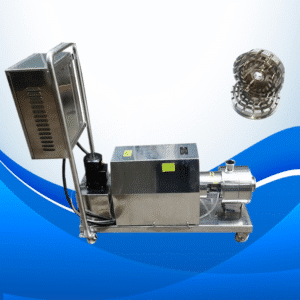

Easy to move and lift

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

Product Description: Inline Mixer Pump for Smooth Industrial Mixing

Overview

Inline mixer pumps play a vital role in factory production lines that need steady, top-quality mixing around the clock. Built for accuracy and long life, this unit blends, emulsifies, homogenizes, and disperses liquids with ease, serving food plants, drugmakers, chemical sites, cosmetic labs, and municipal water works alike.

Key Benefits

- Steady Mixing Every Time: No more batch-to-batch variations; high-shear action delivers the same blend every run.

- Power to Match Your Line: Motor ratings from 1.5 kW to 35 kW and voltages of 110V to 600V lets you plug the pump into almost any setup.

- Tough Housing: Pick standard 304 stainless for mild work, or upgrade to 316L for extra protection in hygiene or harsh-chemical jobs.

- Space-Saving Design: Because it bolts right into the pipe, the mixer pump takes little room and keeps your layout tidy.

Typical Applications & Use Cases

Thanks to its real-time processing and quick rebuild times, the inline mixer pump is a go-to for plants that can’t afford interruptions. Here are a few ways customers put it to work every day:

- Food and Beverage: Mixing syrups, dairy blends, sauces, and dressings without lumps or streaks.

- Pharma Production: Mixes creams, suspensions, and oral liquids evenly while following GMP rules.

- Cosmetics Line: Emulsifies lotions, gels, and pastes with reliable accuracy every batch.

- Chemical Plants: Disperses pigments, stabilizers, and active ingredients smoothly in a running pipeline.

- Water Treatment: Delivers steady doses of additives needed during the purification stages.

From dissolving solids, blending thick liquids, to crafting ultra-fine emulsions, the pump manages many viscosities and particle sizes without strain.

Technical Snapshot

| Feature | Description |

|---|---|

| Power Range | 1.5 kW to 35 kW |

| Voltage Choices | 110 V, 220 V, 380 V, 480 V, 600 V (made to order) |

| Housing Materials | 304 SS or 316L SS |

| Flow Rate | Tailored to the users process |

| Connection Style | Clamp, flange, or threaded |

| Speed Control | With optional Variable Frequency Drive |

Why Pick This Inline Mixer Pump?

- Built for long life and needs little upkeep

- Can be customized to match exact setup

- Customers get full tech support and process advice

- Clean-in-place-ready, so hygiene stays front.

Call to Action

Want to boost your production with a powerful inline mixer pump? Reach out now, and well design a setup that’s just right for you. Whether you run small batches or a fast-moving line, our team will point you to the perfect model.

Frequently Asked Questions

Q1: Which inline mixer pump works best for food production?

A: Go with the 316L stainless steel option; it stays clean and fights rust from sour ingredients.

Q2: Can I use this pump on very thick liquids?

A: You sure can! Well fit it with a motor up to 35 kW so it handles pastes and gels with ease.

Q3: Do you help me plug the pump into my whole system?

A: Of course! Our engineers give step-by-step advice for your setup.

Q4: Is the mixer OK to run 24 hours a day, seven days a week?

A: Yes, it’s built tough, so you get steady performance around the clock.