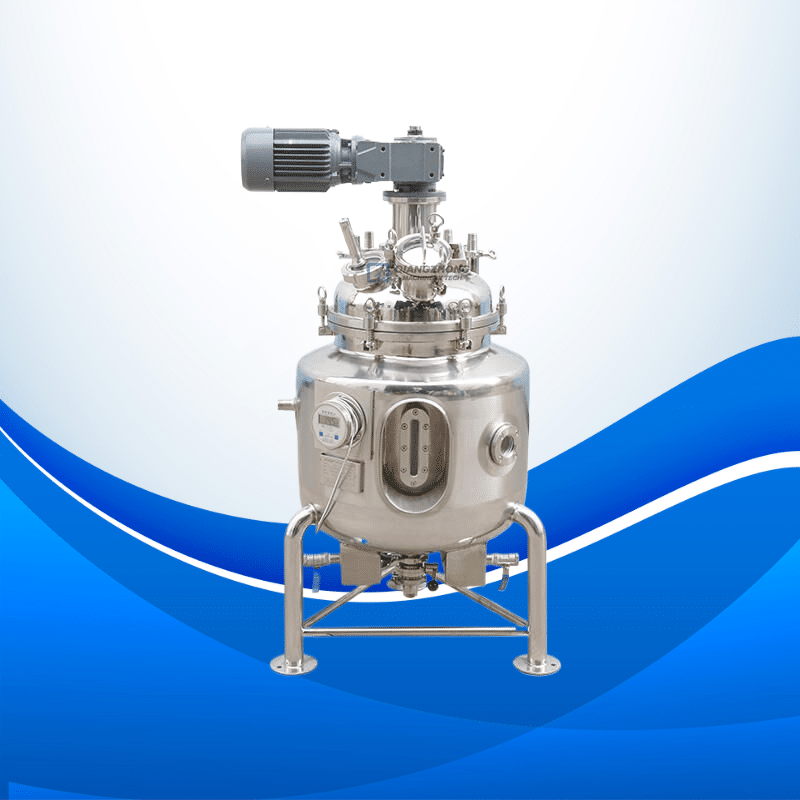

High-Performance Industrial Syrup Mixing Tanks

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$2,650.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Precision Engineered Industrial Syrup Mixing Tank for Reliable and Efficient Production

In any food or drink factory, keeping flavors the same and equipment clean are the top priorities. That is why we built our industrial syrup mixing tank to handle the toughest jobs while staying tidy for years. Whether you mix thick sweet sauces, sugar liquids, or special concentrates, the tank gives you even blending, an easy-clean surface, and dependable long life.

Key Features and Customization Options

Our tank works with many recipes and comes in different setups to match yours exactly. It suits big bottlers and smaller craft brands, offering:

Voltage Options

Pick from 110V, 220V, 380V, 415V, 480V, or even 600V to match your power supply anywhere in the world.

Power Range

Start with 1.5KW for light batches or step up to 55KW for heavy, sticky syrups.

Material Options

Use food-safe 316L stainless for extra corrosion defense, or standard 304 for good protection.

Capacity Range

We build sizes from lab test volumes all the way to giant production tanks, so you get the right fit.

Agitation Technology

Energy-saving agitators stir hard enough to mix every layer and stop crystals from settling out.

Control Systems

Temperature read-outs and speed dials are built in, letting you fine-tune each batch as it cooks.

Real-World Applications

Picture a factory where sticky syrup flows through pipes without clumps and extra ingredients blend in like magic—that’s what our syrup mixing tank was built to do. Here are some places we see it at work:

- Beverage plants whip up sugar syrup, fruit flavor, and water so every can and bottle tastes the same.

- Pharma labs use it to mix sweet cough medicine or children-proof syrup while meeting strict cleanliness rules.

- Dairy makers blend concentrated milk or flavored yogurt, so every batch feels creamy and tastes great.

- Candy factories cook big pots of syrup that need steady heat all the way through, or they end up crunchy.

In every case the tank cleans itself, runs smoothly under heavy loads, and gives operators peace of mind.

Why Choose Our Industrial Syrup Mixing Tank?

- Toughness: High-grade stainless steel shrugs off rust, pressure, and years of daily work.

- Speed: Powerful motors stir tank contents fast and even, cutting overall line time.

- Clean-First: No visible seams, plus optional rinse systems, keep everything sanitary.

- Made-to-Order: Motors, controls, and exterior polish can all be adjusted to fit your floor plan.

- Trusted: Fully tested and stamped to show it meets food factories rules around the world.

Call to Action

Want a mixing tank that mixes syrup quietly, lasts years, and bends to your line? Talk to our crew, and we’ll help you pick off the shelf or build something one-of-a-kind just for your setup.

Request a Quote or Ask for Custom Options — we’re eager to move your line forward.

Frequently Asked Questions

Q: What industries is this mixing tank best suited for?

A: Most food and drink companies, drugmakers, and candy makers buy these tanks.

Q: Is it possible to customize the size or shape?

A: You bet. We’ll craft a tank that fits your floor space and daily output.

Q: Do you offer installation support?

A: For sure. We’ll give you step-by-step tips and remote help when you hook it up.

Q: Can the tank handle high-viscosity liquids?

A: Yes. With the right motor, it easily churns thick syrups or fruit concentrates.

Q: How do I choose between 304 and 316L stainless steel?

A: Pick 316L if your syrup is acidic or salty; 304 works fine for most other foods.