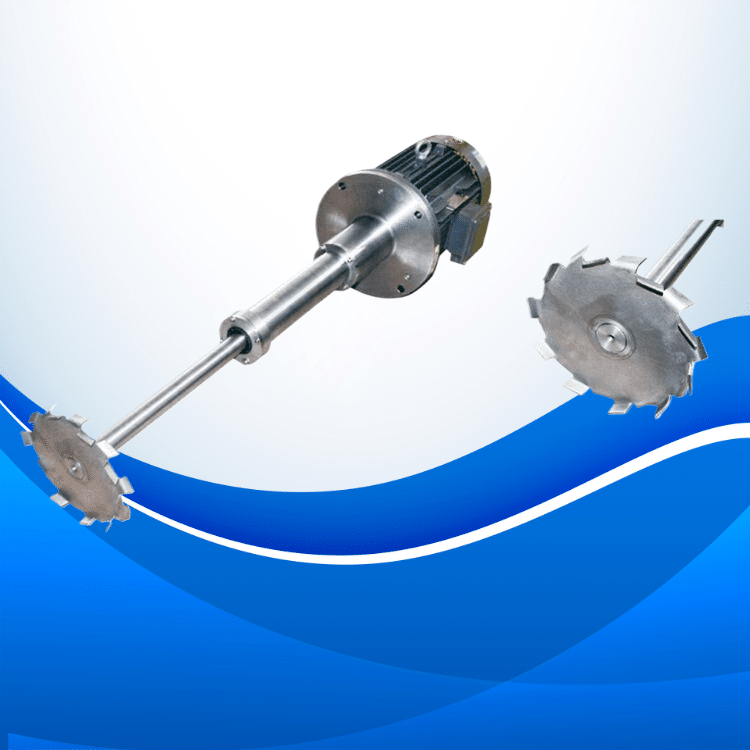

High-Performance Industrial High Shear Mixer

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$680.00

Guaranteed Safe Checkout

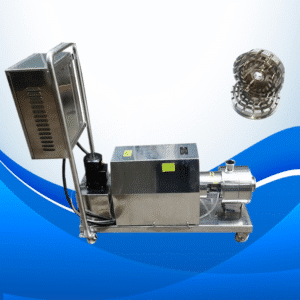

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

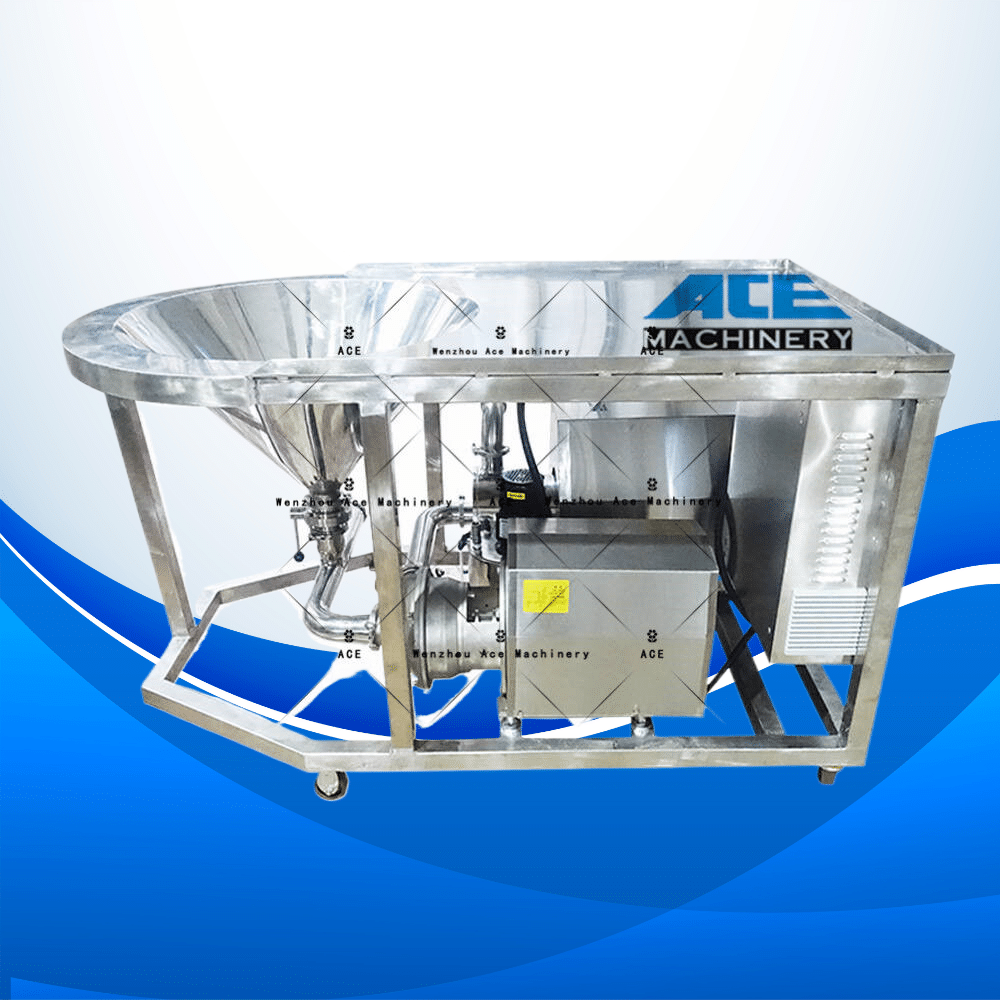

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

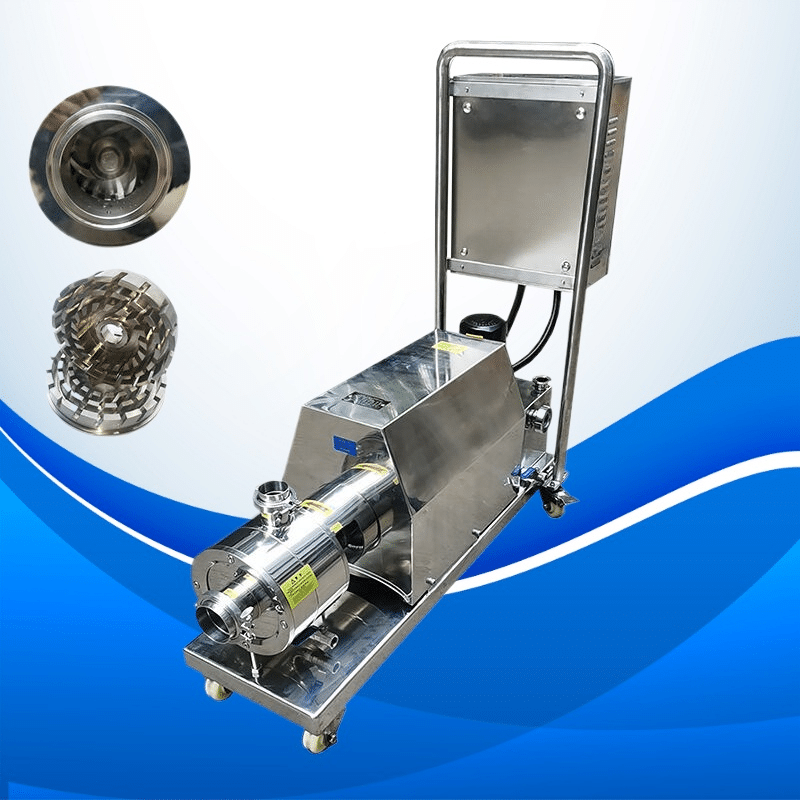

Easy to move and lift

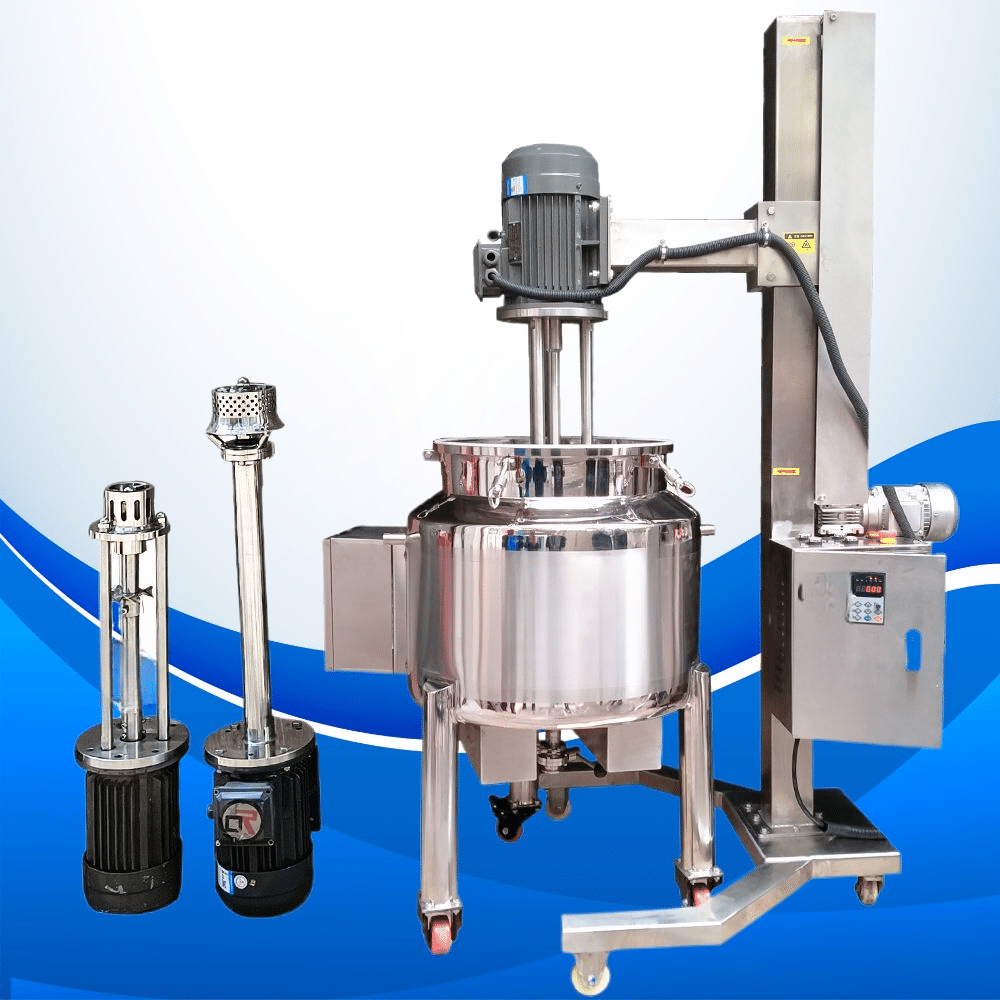

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

Industrial High Shear Mixer – Product Description

Industrial high shear mixers are heavy-duty machines that blend, chop, and melt ingredients super quickly, giving a smooth final product every time. Whether you run a pharmacy, makeup factory, food plant, or chemical line, these mixers cut mixing time in half and keep every batch the same. Plus, they come with tailored extras-stuffed with the right volts, motor power, and steel grade-now ready to slide into your shop floor without a hitch.

Key Features Advantages

High Shear Technology for Superior Blending

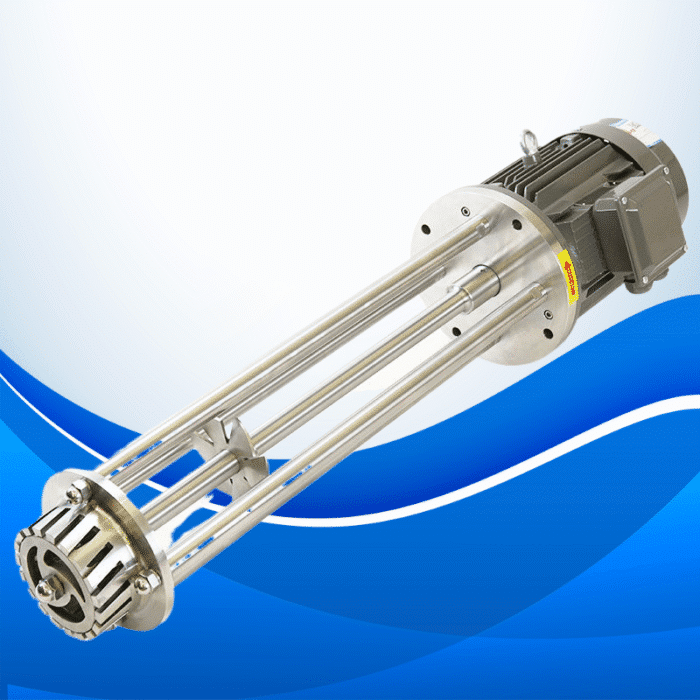

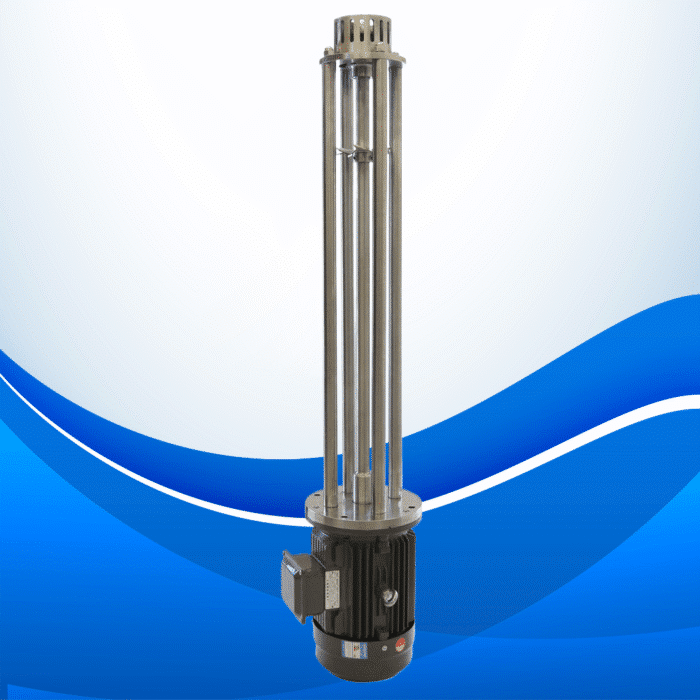

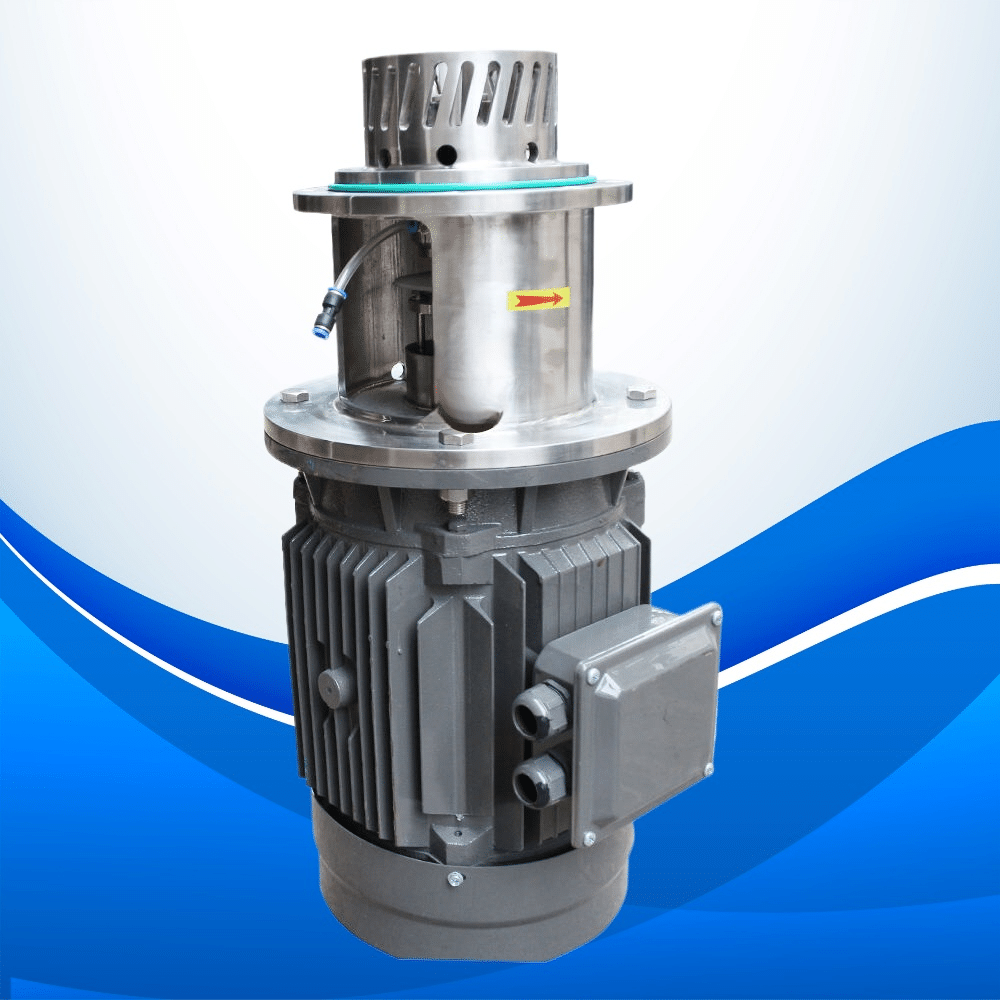

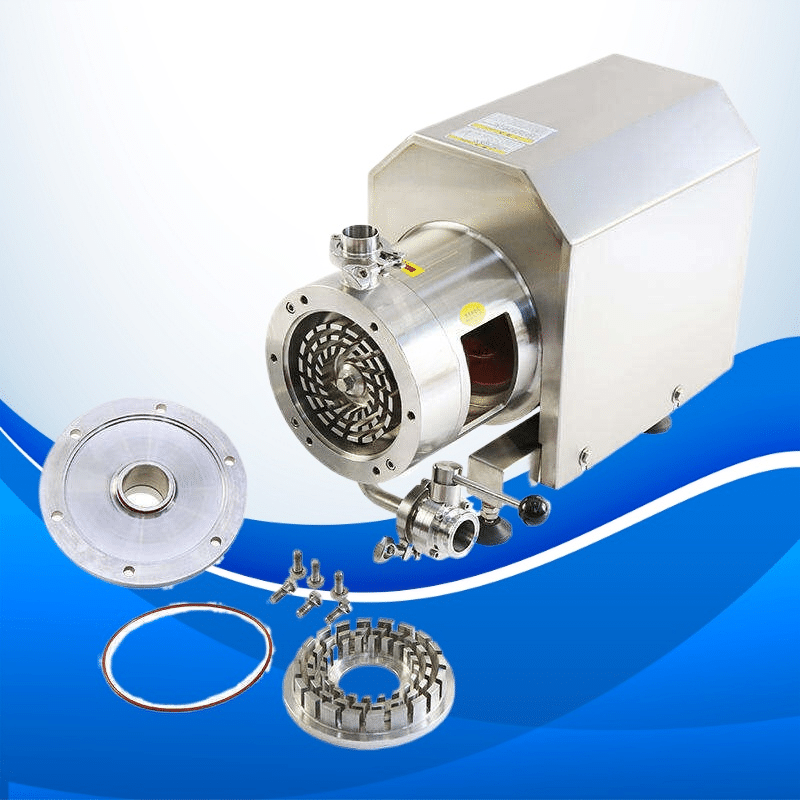

Packed with high-shear rotor-stator sets, the mixer whips through liquids with tornado-like force, smashing particles and folding powders in on themselves. By sealing air pockets, it makes killer emulsions and stable suspensions, yet leaves the goods so smooth you rarely need polishing later.

Customizable Power Options (1.5KW – 35KW)

From a compact lab unit that fits on a table to a beast burning 35KW for a full line, our set-up works for every head of production. Choose wattage from 1.5KW-Coasting through trial runs-to 35KW-Smashing thick sauces-and get the grunt your recipe really needs.

Voltage Range 110V-to-600V

Our high-shear mixer runs on almost any power system, from 110 to 600 volts, so hookup is quick and easy. Whether your plan is to mix batches here in North America or ship machines overseas, you can pick the voltage that matches your factory.

Material Choices 316L-and-304-Stainless-Steel

In a busy plant, mixers must shrug off rust for years, so we build ours out of tough stainless steel. You can choose 316L for the absolute best protection around salty water or cleaning chemicals, or stick with 304 when a good mix of strength and savings is all you need.

Efficient-and-Cost-Effective

Because our mixer blends fast and even, it cuts out extra steps and saves you both time and power. With less material left stuck in the machine, production stays high and waste stays low, turning a simple mixer into one of the smartest buys on the floor.

Wide Range of Applications

Our high-shear mixers fit into a lot of workplaces and handle many different jobs:

- Pharmaceuticals: They turn powders and liquids into smooth emulsions, suspensions, and creams exactly when and how we want.

- Food and Beverage: Teams use them to blend sauces, dressings, juices, and dozens of other products without lumps.

- Cosmetics: Factories count on the mixers to make lotions, balms, and every kind of personal-care cream.

- Chemicals: Mixing chemicals on the same machine cuts changeover time and keeps batches steady and safe.

- Biotechnology: Labs rely on them for breaking down cells and spreading active ingredients evenly through a mixture.

Product Specifications

- Power Options: 1.5 kW to 35 kW, enough punch for small tests or big production lines

- Voltage Options: 110 V to 600 V, ready for outlets worldwide

- Material Choices: Strong 316L or 304 stainless steel that cleans up fast

- Mixer Type: High shear, built to tackle heavy, stubborn mixtures

- Application: Perfect for emulsifying, dispersing, blending, and homogenizing.

How the Industrial High Shear Mixer Works

The rotor-stator design spins the rotor so fast that it drags liquid and soft solids through tiny slots in the fixed stator. That shear force breaks apart clumps and drives powders into the fluid, mixing everything together. Because of the steady stream and strong force, batch time shrinks, energy drops, and product quality stays high.

Applications and Results

Think about the last time you baked-or for a shop owner mixed a new batch of soap. You wanted every spoon of batter or every tub of cream to look and feel the same, right? Our industrial high-shear mixers help you do that in a much larger scale. From silky cosmetic lotions to heavy plant fluids, the mixer spins so fast it breaks particles down evenly, and the speed dial lets you tweak that spin on the fly.

Why Choose Our Industrial High-Shear Mixer?

- Precision and Consistency – TAE soft, foam-free creams or paint that spreads without clumping.

- Customizability – pick the motor size, power voltage, tube finish, or even a welding option that matches your space.

- Durability – steel housing, sealed bearings, and heat-groove cooling mean the mixer keeps running through long shifts.

- Time and Cost Efficiency – shorter blend times cut labor and the smart motor eats less wattage.

- Industry-Specific Applications – the design meets rules set by pharma, food, footwear, or chemical plants, so inspections go smoother.

Call to Action

Curious how our mixer could improve your line? Whether you run kitchen test batches or a million-tube factory, our engineers will size, test, and quote a match in days. Reach out now for a free consultation, CAD drawings, or to lock in your unit. The queue is rolling, and each build is tailored, so the sooner you call, the sooner the mixer starts earning money for you.

Frequently Asked Questions (FAQ)

What’s the main difference between 304 and 316L stainless steel?

316L offers better rust and stain resistance, so it’s often used in food, drug, and chemical settings where cleanliness and strength matter most. 304 usually costs less, so it works well in jobs that aren’t as tough on material.

What power ratings do your high-shear mixers come in?

Mixers range from 1.5 kW up to 35 kW. The best size for you really depends on how much you produce and how thick the mix is.

Is the industrial high-shear mixer safe for food and drinks?

Yep! Our mixers meet food-grade standards and give even blending for sauces, drinks, and lots of other products.

What voltage can I get for the mixer?

You can choose anywhere from 110 V to 600 V, based on the power setup in your area. Just tell us what you need, and well wire it that way.

Can I order a mixer built to my exact specs?

For sure! We do custom materials, power, size, and more—whatever fits your process. Reach out and well work out the details together.