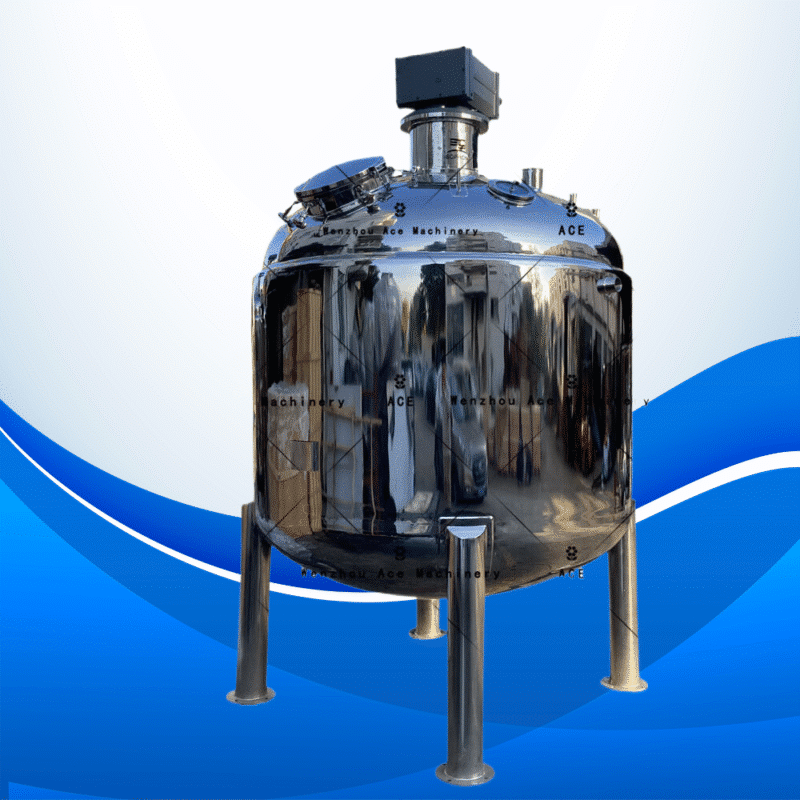

High-Performance Heating Element Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,100.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Introduction

If your work needs spot-on temperature control and smooth blending, the Heating Element Mixing Tank is the tool you want. Built for tough factory floors, it pairs strong heating with steady mixing, so every batch comes out the same, no matter what job you throw at it.

Key Features & Advantages

- Custom Voltage Range (110V TO 600V): Works with almost any power source, from a small bench-top lab outlet to the big three-phase lines in a full production plant.

- Flexible Power Output (1.5KW 55KW): Pick the wattage that matches your heating speed and busy hours, so you never waste energy or time.

- Premium Material Options: Comes in tough 316L stainless for salty or acidic formulas, or 304 stainless when standard durability is all you need.

- Efficient Heating Elements: Fast-acting electric coils raise the temperature quickly and keep it locked in, even for heat-sensitive blends.

- Sturdy Agitation System: Heavy-duty paddles or blades mix everything from thin liquids to sticky paste without dead spots, and you can swap impellers to suit each recipe.

Typical Use Cases

- Food Beverage: Heat and stir syrups, sauces, creams, or cooking oils safely and up to code.

- Pharmaceutical Cosmetic Manufacturing: Keep gels, lotions, and delicate actives at the right temperature during every step.

- Chemical Processing: Combine powders or liquids that need gentle heat so they don’t burn, bubble, or react unexpectedly.

- Coat, glue, and resin jobs flow better when thick liquids blend evenly and stay cool enough not to scorch.

- Breweries and distilleries reach smoother mashes when gentle, warmed mixing kicks off fermentation.

Specifications at a Glance

| Feature | Choices |

| Voltage | 110V to 600V options |

| Power | 1.5 kW to 55 kW |

| Shell Material | 304L or 316L stainless |

| Tank Volume | Made to your needs |

| Temp Control | Choose digital or dial |

| Agitation Speed | Variable on request |

Custom-Ready and Scalable

Take a laboratory batch line to full market or simply boost an aging floor; our tanks come built-to-spec. PLC links, clean-in-place plumbing, and plug-and-play temperature control slide easily onto any order.

Why Partner With Us?

- Decades-long fabrication track record

- Dedicated in-house engineers

- Quick quotes and even faster builds

- Worldwide voltage and cert standards

- Optional on-site setup and operator training

Time to Supercharge Your Heating and Mixing?

Lock in a Heating Element Mixing Tank that matches your output goal, then click Request a quote for pricing and lead-time info. Engineers also walk you through the best layout and features.

📌 Frequently Asked Questions (FAQ)

Q1: What industries use heating element mixing tanks?

A: You’ll mostly find them in food factories, drugmakers, beauty-product lines, chemical plants, and breweries.

Q2: Can I customize the tank for my process requirements?

A: Absolutely. You decide the voltage, wattage, size, mixer style, and material, so it fits your workflow exactly.

Q3: What is the lead time for production and delivery?

A: Most orders ship in 2 to 6 weeks, but that depends on the level of custom work and how many you buy.

Q4: Are your tanks certified for sanitary use?

A: Yes, the 316L stainless steel meets food and pharma rules, and papers like ASME, CE, or FDA can be sent if you ask.

Q5: Do you offer installation support?

A: For a small extra fee, our team will come out, hook everything up, and make sure it runs smoothly with your system.