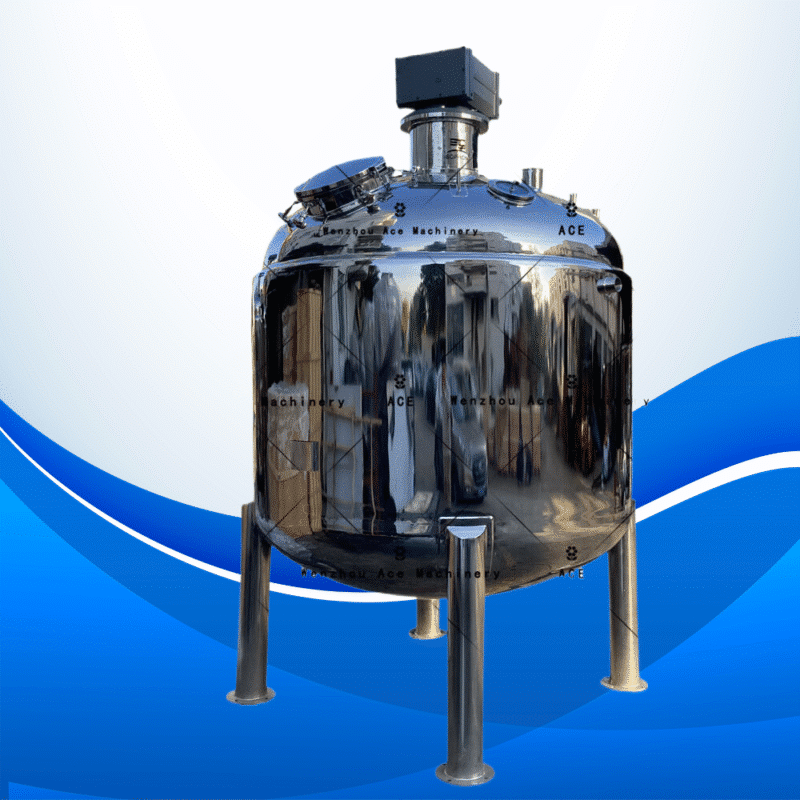

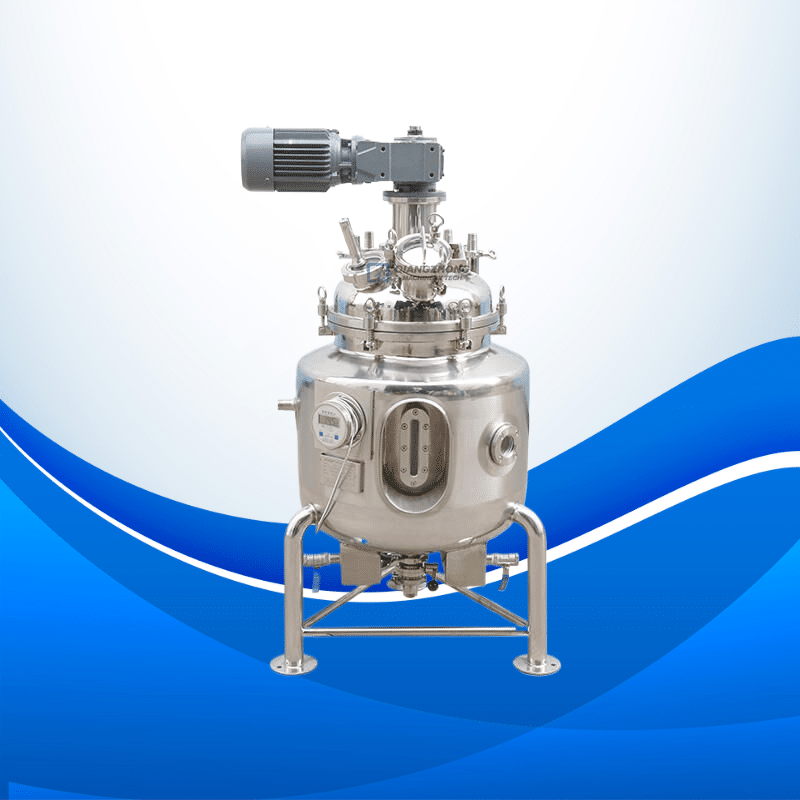

High-Performance Chemical Mixing Tank with Agitator

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$5,600.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Our chemical mixing tank with agitator is a tough, reliable workhorse for any plant that needs to blend chemicals fast and evenly, whether you are stirring thin liquids or mixing thick slurries that need an extra push. Designed for harsh floors and busy lines, the unit pairs a roomy, heavy-wall tank with a high-speed agitation system so every drop, bead, or crystal ends up in the same uniform batch.

Main Features and Benefits

Custom Voltage Range

Wire it for anything from 110V in a small lab to 600V in heavy industrial use.

Flexible Power Options

Pick a motor from 1.5kW for light loads up to 55kW when viscosity or product weight demands more spin.

High-Grade Materials

Shells come in food-safe 304 stainless for most jobs or tougher 316L for salty, acidic, or abrasive chemicals.

Precision Agitator Design

Blade shapes and shaft angles are tested to push liquid where it needs to go, with almost no stagnant pockets.

Scalable Capacity

Tank volumes from 100 liters to 10,000 liters, made to fit pilot lines or full-production plants.

Application Scenarios

This mixing tank shows up in every corner of heavy industry:

Pharma

Combining active ingredients with powders or solvents without cross-contamination.

Water Treatment

Dissolving polymers, coagulants, or acid buffers for clearer, safer effluent.

Cosmetics

Blending oils, waxes, and preservatives into smooth creams under clean-room rules.

Food & Beverage

Adding colors, flavors, or fortifying agents in an ANSI-grade, easy-to-clean system.

Paints & Coatings

Making sure pigments and resins blend in every batch.

Imagine a mixer that keeps the right temperature, cuts down big-bit variability, and keeps your crew away from avoidable hazards. Whether you’re ramping production or fine-tuning quality, our equipment works steadily day after day.

Why Pick Our Gear?

- 316L stainless steel gives top-notch rust protection in acidic or basic formulas.

- Energy-smart motors shrink the monthly power bill.

- Small footprint lets you clean and service without moving half the factory.

- CE mark standard, plus optional ATEX for high-risk areas.

- Build-to-order from tank size to blade shape.

Customization Options

- Voltage: 110V, 220V, 380V, 415V, 480V, 600V

- Horsepower: 2HP to 75HP

- Shell: 304 or 316L stainless steel

- Controls: Basic switch panel or full PLC setup

- Mounting: Fixed pad, rolling cart, or trailer

Call to Action

Want to boost your chemical line? Reach out for a free chat and a quote shaped just for you. Our engineers stay with you from first sketch to smooth start-up.

FAQ Section

Q: What size mixing tank should I choose?

A: It depends on your batch volume, fluid thickness, and how long you mix. We can help you pick the perfect tank every time.

Q: Can this setup mix thick, sticky liquids?

A: For sure—our heavy-duty mixers and the right blade style let it work with all kinds of thickness.

Q: Can the tank hold flammable or dangerous chemicals?

A: Yep, we have ALEX-certified units and spark-proof motors you can add if you need them.

Q: Once I order a custom design, how long until it ships?

A: Usually, you’ll get your unit in 3 to 6 weeks, though smaller changes can speed that up.