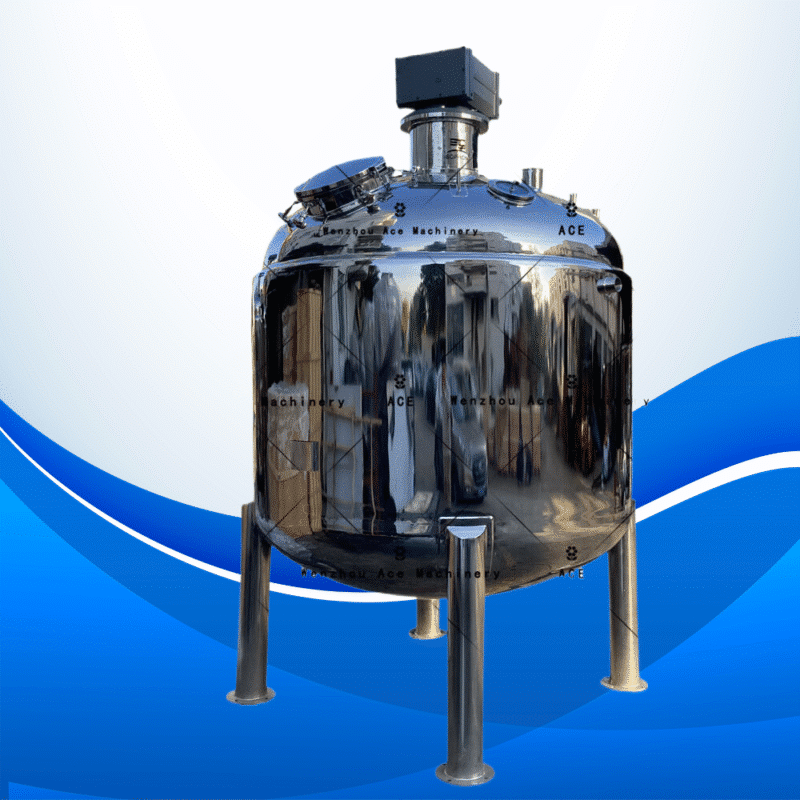

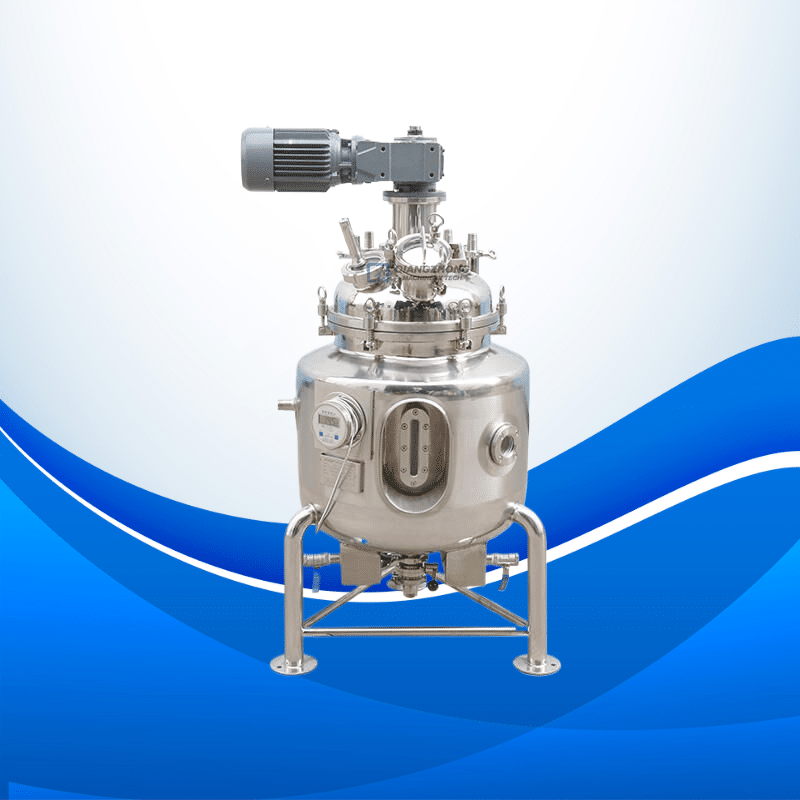

High-Performance Chemical Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,310.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Chemical Mixing Tank: The Secret to Smooth and Safe Mixing on the Floor

When keeping a worksite snappy and secure matters most, a well-built chemical mixing tank quickly stops being optional and starts being vital. From farmers who need even fertilizer blends to drugmakers counting active ingredients, knowing that each batch is mixed the same way time after time can lift quality and speed on the line. Our tanks pair a rugged build, clever mixing gadgets, and custom tweaks, so the system fits your floor instead of making your floor fit the system.

Key Features of Our Chemical Mixing Tank

Material Options:

Pick the finish that fights rust best for your job:

- 316L Stainless Steel: Tough enough for strong acids and pure enough to pass pharma rules.

- 304 Stainless Steel: Eager to take on most chemicals while costing a little less than its big brother.

Voltage and Power Flexibility:

Every shop in the world runs juice a little differently, so our tank can slide from 110V house circuits to 600V heavy-feed loops. Power ratings start at a handy 1.5KW for small test batches and climb to 55KW for giants that stir whole truckloads.

Customizable Design:

Every plant has its own quirks and needs. Our chemical mixing tanks come with adjustable features so they fit right into your setup. Need a different mixer shape, heat pins, chill coils, or smart controls? Just ask, and our team will build exactly what you want.

Durable and Efficient Mixing:

A good recipe is only as strong as the mix. That’s why our tanks use high-tech stirrers that move every ingredient the same way, every time. You get steady product quality and save on power, because the mixer works smarter, not harder.

Safety and Compliance:

Safety isn’t optional; it’s our starting point. Each tank passes every major guideline worldwide, so you can focus on production instead of worry. Clean-out ports and quick-access panels also cut maintenance time.

Applications of Chemical Mixing Tanks

Our tanks cross industries, so one design adapts to many tasks:

Chemical Manufacturing:

When every batch must taste the same, our mixers deliver repeatable results for paints, glues, and specialty recipes.

Pharmaceuticals:

From tablets to lotions, our tanks make sure each dose stays pure, all while ticking the boxes that auditors care about.

Food and Beverage:

Mixing tanks for the food world must meet strict safety rules. Whether you’re making drinks, sauces, or dressings, our tanks blend everything evenly while keeping contaminants out.

Cosmetics:

Smooth creams, light lotions, or clear gels all need a steady stir as they come together. Our tanks give that gentle, even motion, helping makers craft top-quality beauty products.

Wastewater Treatment:

Plants that clean sewage or industrial runoff demand serious mixing power. Our gear blends chemicals with real accuracy, making it a trusted choice for tough treatment jobs.

Key Technical Parameters

- Material: 316L Stainless Steel, 304 Stainless Steel

- Voltage Options: 110V, 220V, 380V, 440V, 600V

- Power Options: 1.5KW, 3KW, 5.5KW, 11KW, 22KW, 55KW

- Tank Capacity: Custom sizes (up to several cubic meters)

- Agitator Type: Customized (Propeller, Anchor, Turbine)

- Design Features: Heating, Cooling, Jacketed, Insulated

Why Choose Our Chemical Mixing Tank?

Exceptional Performance:

Each tank is built to mix fast and quietly, cutting waste and speeding up your line.

Customization:

Tell us what you need, and we tailor the steel grade, motor, blades, and extras just for you.

Durability:

Our mixing tanks use top-grade 316L and 304 stainless steel, so you get strong walls that resist rust and last a long time. Because of that, you spend much less time and money fixing or replacing them.

Energy Efficiency:

You can pick a heating element from 1.5kW up to 55kW, so the tank uses only as much power as your operation needs. That means it mixes fast without eating up energy when the job is light.

Call to Action: Design Your Perfect Mixing Tank Today!

Ready to boost your line with a dependable mixing tank? No matter if you make chemicals, meds, food, or beauty products, we can build a unit that fits your setup.

Reach out for a quick quote, tweak the details, and watch your process improve with equipment that mixes accurately and runs steadily all day.

Frequently Asked Questions (FAQ)

Q1: What materials are the mixing tanks made of?

We build our tanks in either 316L or 304 stainless steel. 316L stands up to tough, corrosive liquids, while 304 works well for milder chemicals and costs a bit less.

Q2: Can the tank be customized to fit my specific needs?

Absolutely! You choose the size, agitator style, heater strength, and extras like cooling jackets or sight glasses.

Q3: What voltage options are available for the tank?

You can get our tanks in all the common voltages, from 110 volts up to 600 volts, so they should match the power supply at your location.

Q4: What industries use chemical mixing tanks?

These mixing tanks show up everywhere-good factories, pharmacies, bakeries, beauty plants, and even in places that treat wastewater.

Q5: How can I place an order?

Ordering is simple; just visit our site or call a customer rep, and they will walk you through picking options and adding any custom features.