High-Efficiency Inline Shear Mixer for Precise Industrial Mixing

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$2,400.00

Guaranteed Safe Checkout

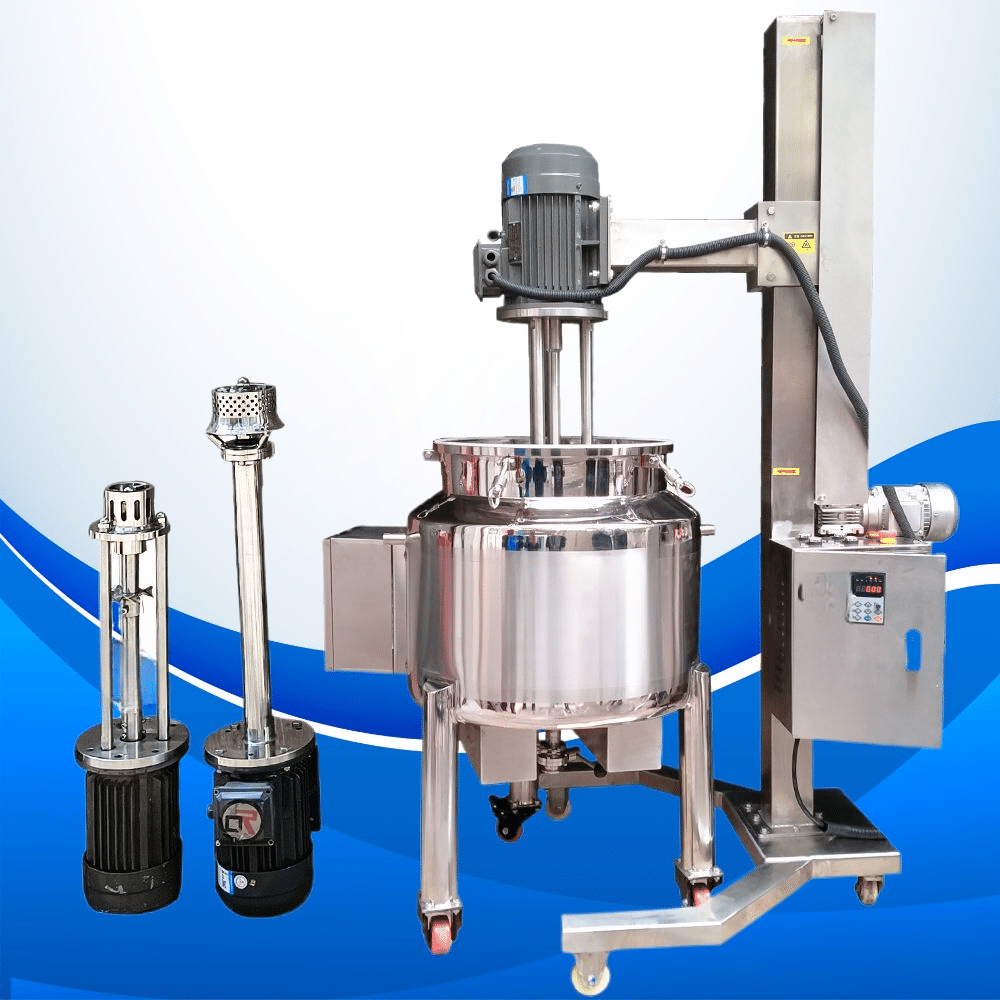

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

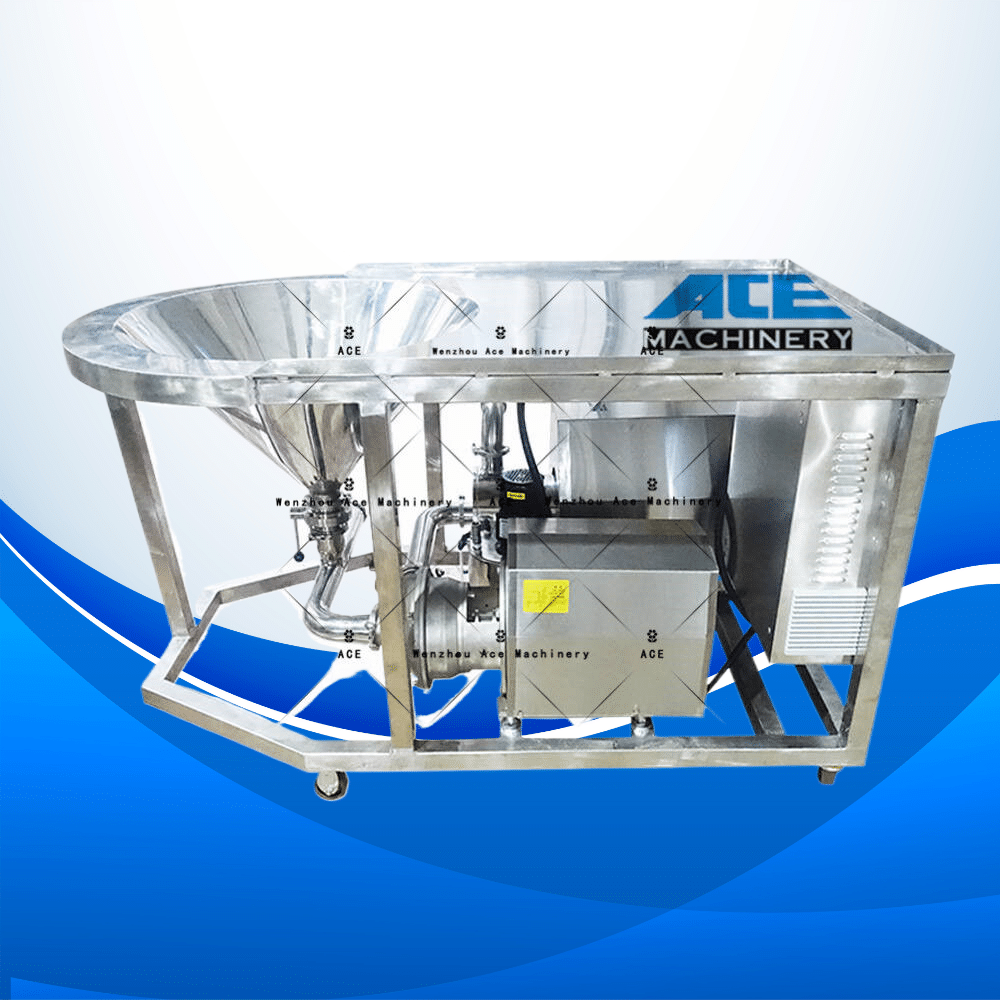

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

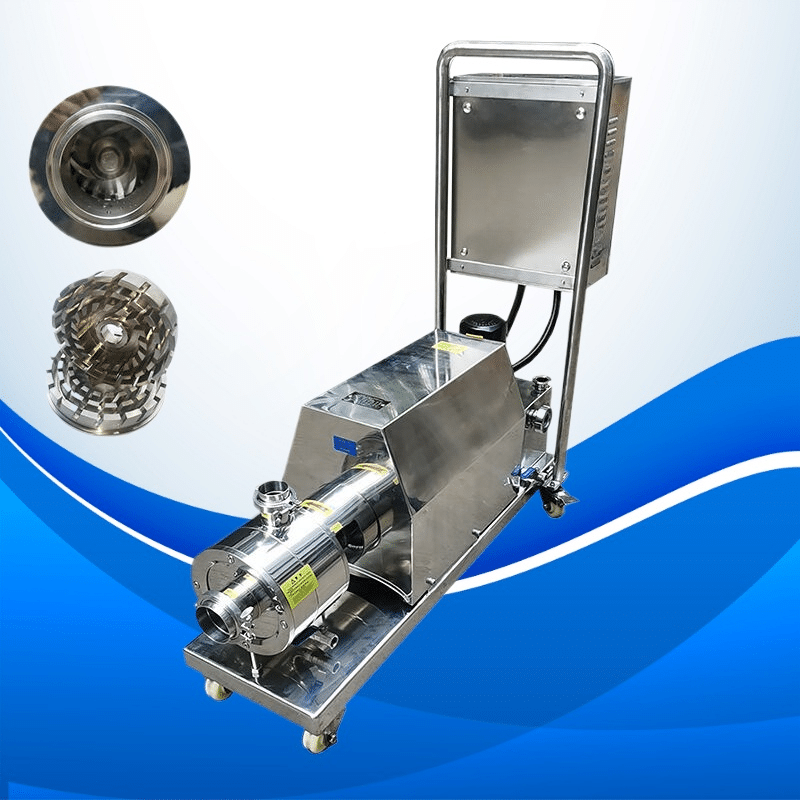

Easy to move and lift

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

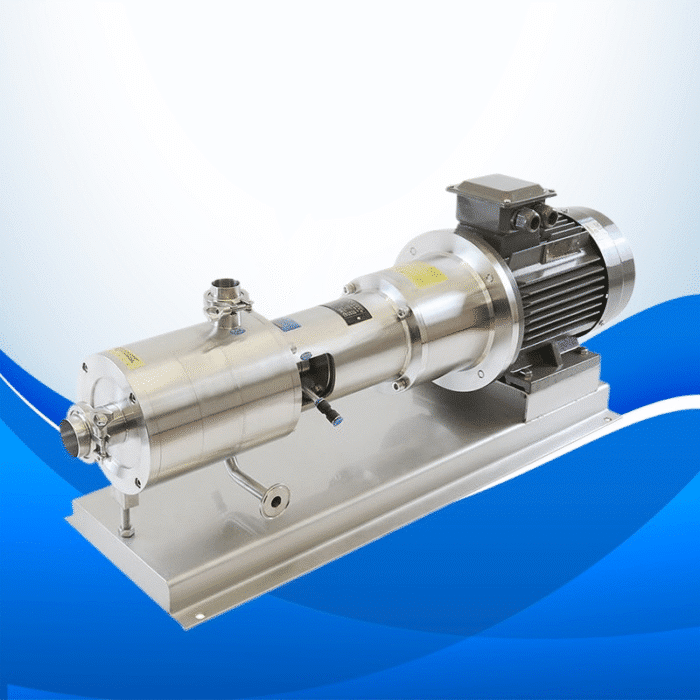

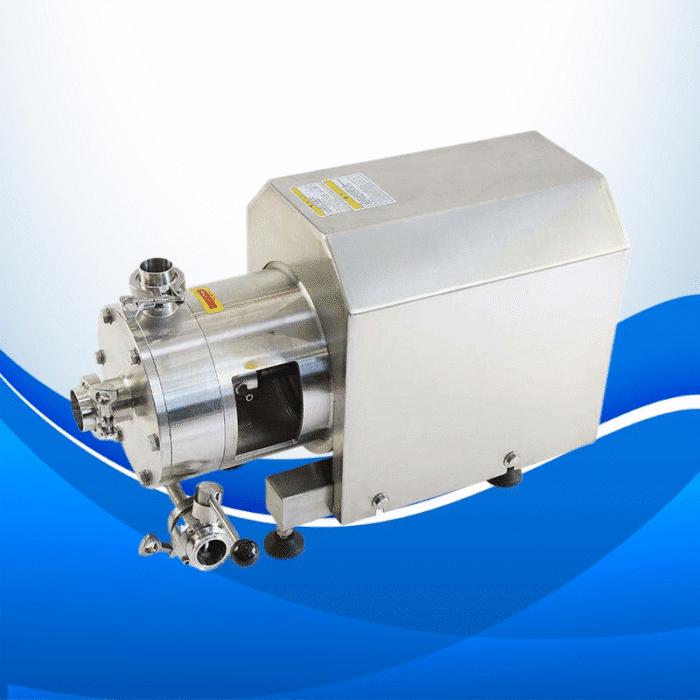

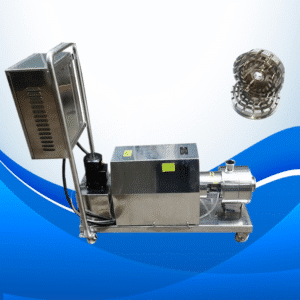

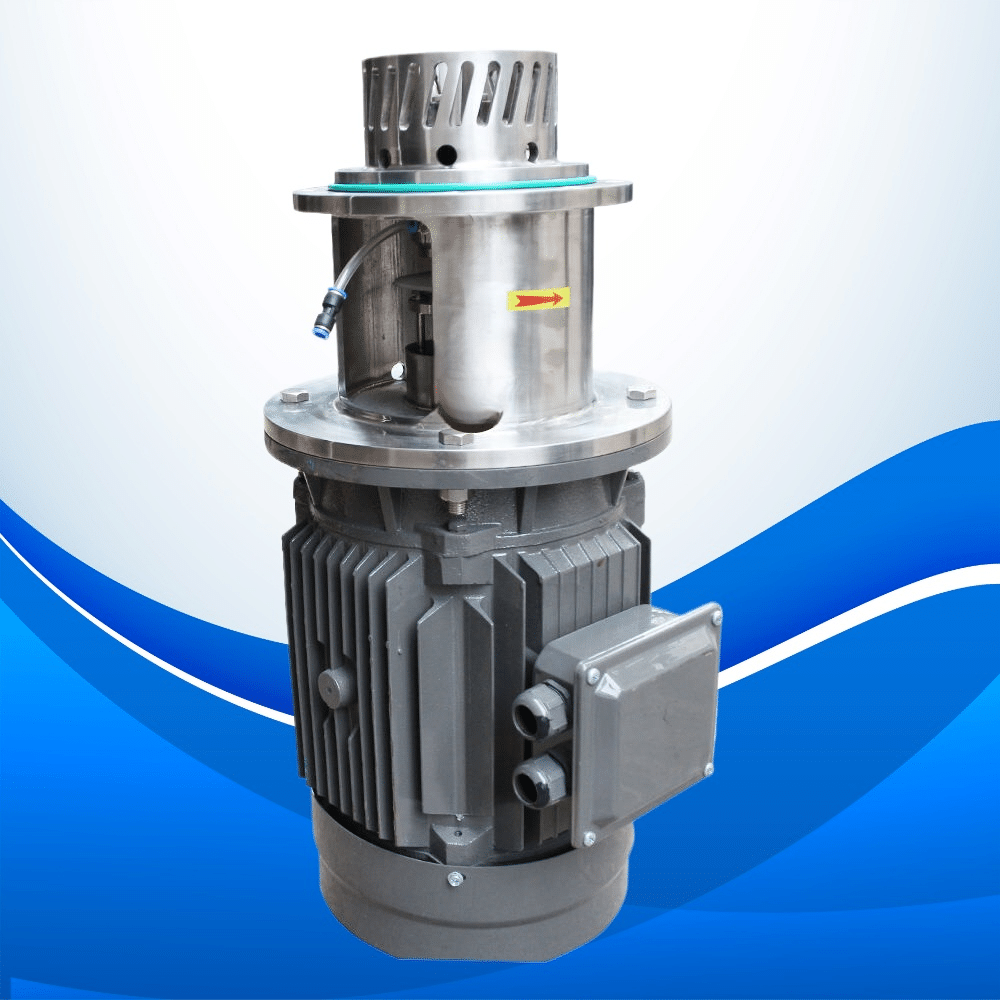

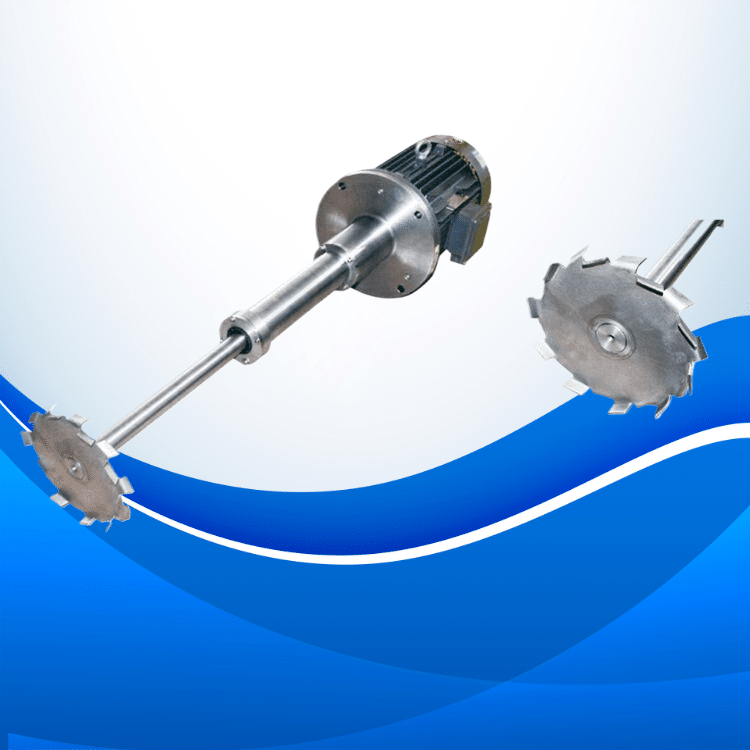

Product Description: Inline Shear Mixer for Precision Industrial Mixing

Introduction: Professional Inline Mixing Made Simple

If your work involves food, makeup, medicine, or industrial chemicals, you know that mixing must be exact and steady from the first drop to the last. Our inline shear mixer does just that by pulling product right out of the pipe, chopping, blending, and pumping it onward. That means no waiting for thanks to fill, no risk the blend sits too long, and a finish you can trust.

Designed with flexibility in mind, the mixer bolts into lines already up and running, scales easily as demand grows, and can be tailored with extra sensors or power packs so it matches any plant layout.

Key Advantages of Our Inline Shear Mixer

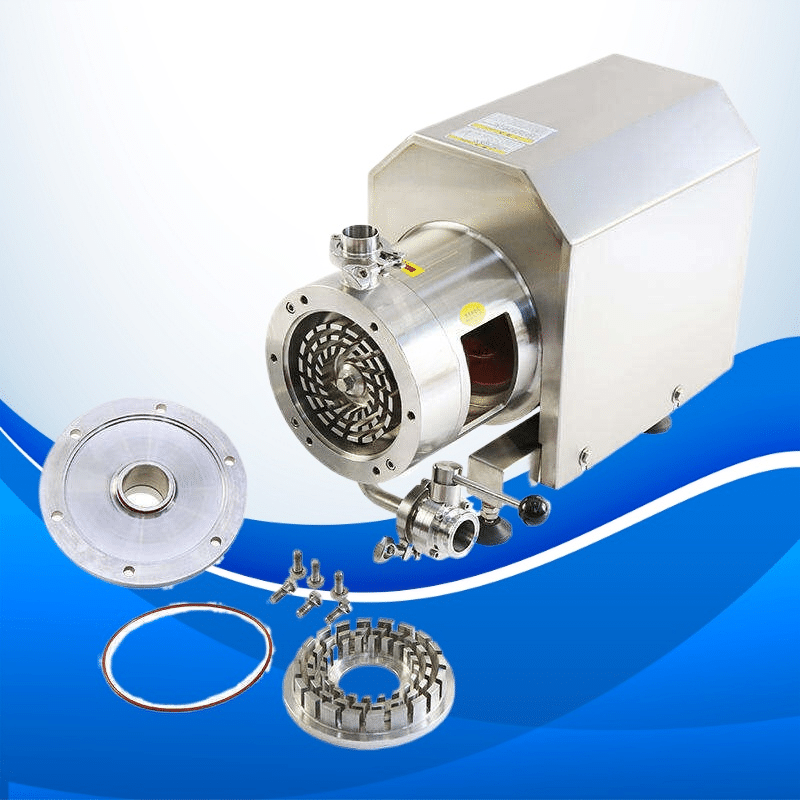

- High Shear Efficiency: Rotating blades cut and swirl fast enough to crush lumps, spread oil in water, or blend powders with zero grit.

- Continuous Operation: Pipe-to-pipe setup frees you from draining vessels and lets operators check quality on the fly.

- Customizable Power Options: Range starts at 1.5 kW for lab tests and climbs to 35 kW for food giants churning out thousands of liters.

- Voltage Flexibility: Pick 110V, 400V, or any other standard and the controller keeps motors happy.

- Premium Construction: Choice of 304 or 316L stainless steel stops rust, shrugs off acids, and meets all hygiene rules.

- Compact Footprint: Short, narrow body slides under most overhead pipes, needs only a wipe-down now and then, and leaves plenty of room for valves.

Real-World Applications: Where Performance Matters

Think about how much smoother your day would go if clogs, inconsistent blends, and endless mixing cycles just vanished. Plug in our inline shear mixer, and that wish becomes routine. Here’s what it does across industries:

1. Food & Beverage

- Turn sauces, dressings, and dairy into the same silky texture every time.

- Make drinks feel richer while cutting back on extra stabilizers.

2. Cosmetics & Personal Care

- Whip up creams, lotions, and gels until they’re smooth-no lumps allowed.

- Shorten processing hours and lock in longer-lasting emulsions.

3. Pharmaceutical

- Form ultra-fine emulsions and suspensions for ointments, syrups, and injectables.

- Meet every GMP detail with repeatable results you can trust.

4. Chemical & Petrochemical

- Spread pigments, polymers, and boosters in paints, lubricants, and coatings.

- Keep dispersion steady-no agglomerates, even in thick mixes.

Technical Specifications At-a-Glance

| Feature | Options |

|---|---|

| Power Output | 1.5 kW – 35 kW |

| Voltage | 110V, 220V, 380V, 415V, 480V, 600V |

| Material | 304 SS or 316L SS |

| Flow Capacity | Tailored to your process |

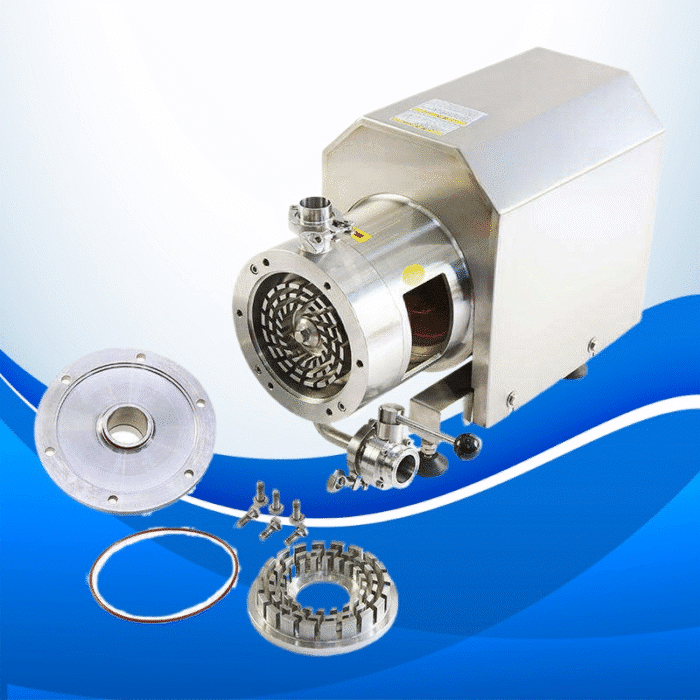

| Rotor-Stator Design | Modular high-shear head |

| Cleaning | CIP-compatible (Clean-In-Place) |

Why Choose Our Inline Shear Mixer?

- Global Compatibility: Pick a power and voltage range that matches your local supply, and you’re ready to roll.

- Durable Materials: 316L stainless steel stands tough in high-purity or aggressive settings, protecting your product and your plant for years.

- Scalable Performance: Start with a small pilot model, then scale up as production grows, broaden capacity with additional mixers later.

- Expert Support: Our engineers guide you from selection through integration and continue backing you with friendly after-sales service.

Customization Options Available

Make your inline shear mixer fit your process. Choose from rotor-stator setups, sanitary upgrades, and other features:

- custom inlet and outlet sizes

- variable-speed drives

- explosion-proof motors for hazardous zones

- jacketed housing for thermal control

Call to Action – Get Your Custom Inline Shear Mixer Today

Ready to level up mixing speed and smooth production? Our team will help you plan the perfect inline shear mixer for your industry.

Contact us now for a quick quote or a free chat with a product specialist. Need something special? We promise to build it.

Frequently Asked Questions (FAQ)

- Q1 – What size inline shear mixer do I need?

A – It depends on volume, fluid thickness, and what you are mixing. Our engineers will match you to the ideal model. - Q2 – Can I use this mixer in a clean room or GMP environment?

A – Yes, when we build it with 316L stainless steel and sanitary seals. - Q3 – Do you offer on-site installation and training?

A – Absolutely; our team travels worldwide to help you set up and train operators. - Q4: How do I clean the mixer?

A: The mixer is made for full CIP cleaning and also pulls apart easily if you want to wash it by hand.