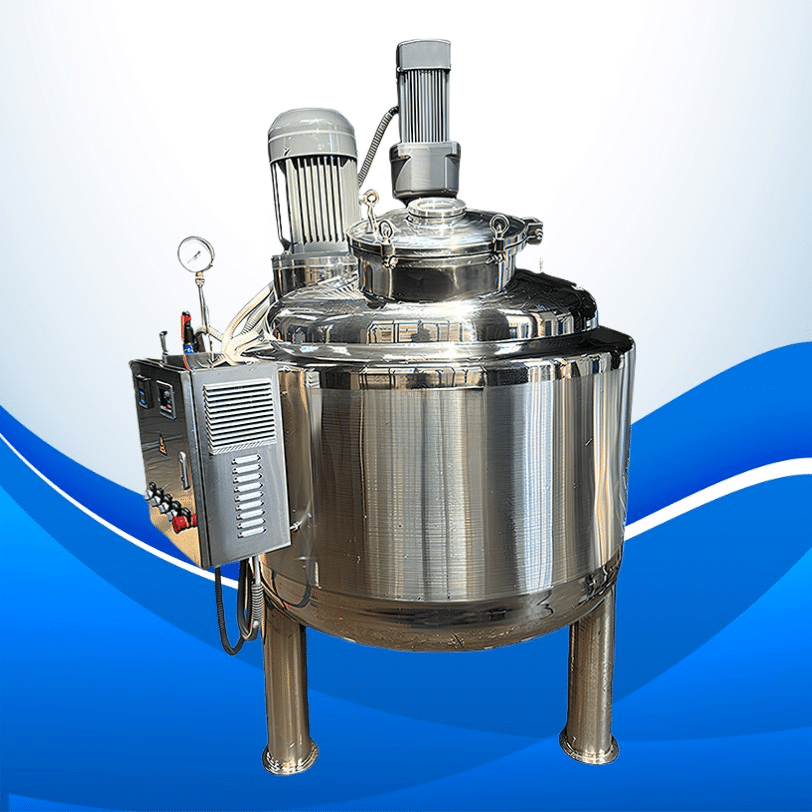

High-Efficiency Electric Heating Syrup Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,400.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Product Overview

Our electric syrup-heating tank is made for makers who need dependable, spot-on heating and a little extra flexibility. Whether you’re stirring up caramel, fruit syrups, jams, glazes, or sauces, the tank heats evenly, stands up to everyday use, and offers power options that match your operation size.

Key Advantages

🔥 Precise Temperature Control

A wide choice of voltages from 110 to 600 V and power ratings from 1.5 to 55 kW let you set the heat level that fits your batch size—whether it’s a hand-crafted kettle or a full-scale factory run.

Built-in PID controllers and adjustable mixing speed keep every spoonful at the same steady temp while smoothing out any lumps.

🛡️ High-Quality Construction

Pick medical-grade 316L or standard 304 stainless steel for strength you can trust.

Seamless welded surfaces stop gunk from hiding, make cleanup quick, and cut the risk of cross-contamination.

🔄 Efficient Mixing Performance

Swap in anchor, paddle, or turbine agitators and dial the speed up or down to blend without burning or crystalizing.

A fully jacketed body spreads heat from edge to edge, so there are no hot or cold spots.

🚀 Scalability & Integration

Start with a countertop model, then move up to tall floor units that hold over 2000 liters as your needs grow.

Optional plug-and-play control panels save recipes, run CIP cycles, track time, and talk directly to your automation system.

Real-World Applications

Candy and Baking

Heat and blend caramel, toffee, fudge, glazes, or fruit fillings, so every batch tastes and feels the same.

Drinks

Mix hot syrups, fruit concentrates, or cocktail bases, and serve with a taste and texture customers can always trust.

Sauces and Dressings

Keep chocolate, BBQ, teriyaki, or mustard sauces perfectly blended and balanced from the first spoonful to the last.

Pharma and Cosmetics

Make small batches of creams, gels, and sanitary syrups in a clean space that meets industry guidelines.

Picture the Scene:

You pour cold caramel into a kettle, set the dial, and a soft heat rises while a slow paddle tumbles it just enough—no clumps, no burns. When it’s done, wipe the flat stainless finishes, and twenty minutes later the kitchen is spotless.

Technical Specs

| Parameter | Options/Details |

|---|---|

| Voltage | 110 V, 220 V, 380 V, 415 V, 480 V, 600 V (single- or trio-phase) |

| Power | 1.5 kW to 55 kW, set on-site to match your needs |

| Materials | Tank walls in rugged 316L or 304 stainless steel |

| Heating | Clamp-on electric jacket, temp tuned by smart PID control |

| Mixing | Choose anchor, paddle, or turbine, plus variable-speed drive |

| Size | 50 L up to over 2,000 L for small runs or bulk orders |

| Control | Built-in temp probes, real-time timer, optional PLC or touch-screen |

| CIP | Quick-connect clean-in-place system for zero-worry sanitation |

Why Pick Our Tank

- Custom Volt and Watts run any plant, from craft kitchens to big bottlers.

- 316L or 304 steel fights rust, meets food rules, and stretches years.

- PID heat and speed control make each batch an even syrup or sauce.

- Snap-off parts and the CIP option cut cleaning time, not production.

📞 Call to Action

Want to take your syrup or sauce setup to the next level? Drop us a line, and we’ll map out the right size, power, and features for you. We provide:

- Custom tank sizes, heating power, and layout

- Food-grade 316L or 304 stainless steel

- Smart control add-ons: PID, PLC, or full automation

Enjoy repeatable batches, quick clean-up, and spot-on heating — grab your electric syrup mixer today!

Frequently Asked Questions (FAQ)

Q: Can I pick either 110 V or 600 V?

Definitely! Our tanks run from 110 V to 600 V, single or three-phase, so they fit your shop.

Q: Which stainless steel should I pick, 316L or 304?

316L resists rust better, which matters for acidic syrups, but 304 is still safe and easier on the budget. We’ll guide you based on your recipe.

Q: How do I clean it?

Smooth surfaces and an optional Clean-In-Place (CIP) setup mean you often skip scrubbing by hand.

Q: Does it heat evenly?

For sure — the electric jacket plus PID control stops hot and cold spots, giving steady temp from top to bottom.

Q: Can you build a custom size?

You bet! We make tanks as small as 50 L for lab use, up to over 2,000 L for factories. Send your numbers and we’ll quote exactly what you need.