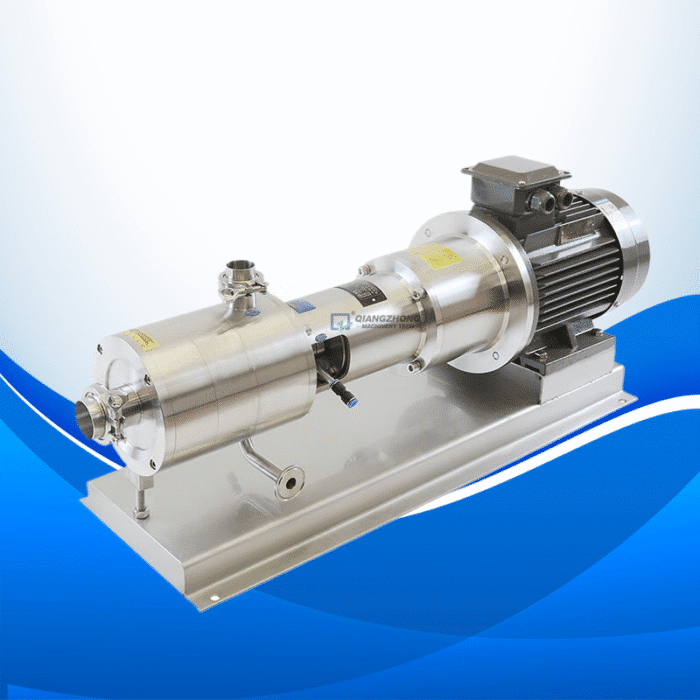

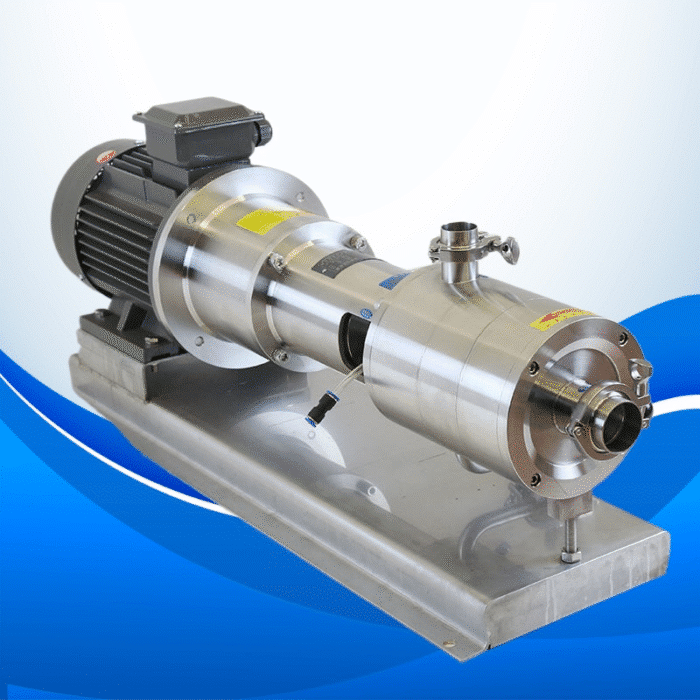

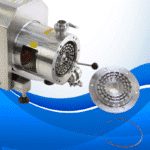

High‑Performance Inline High Shear Mixer

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$1,560.00

Guaranteed Safe Checkout

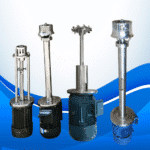

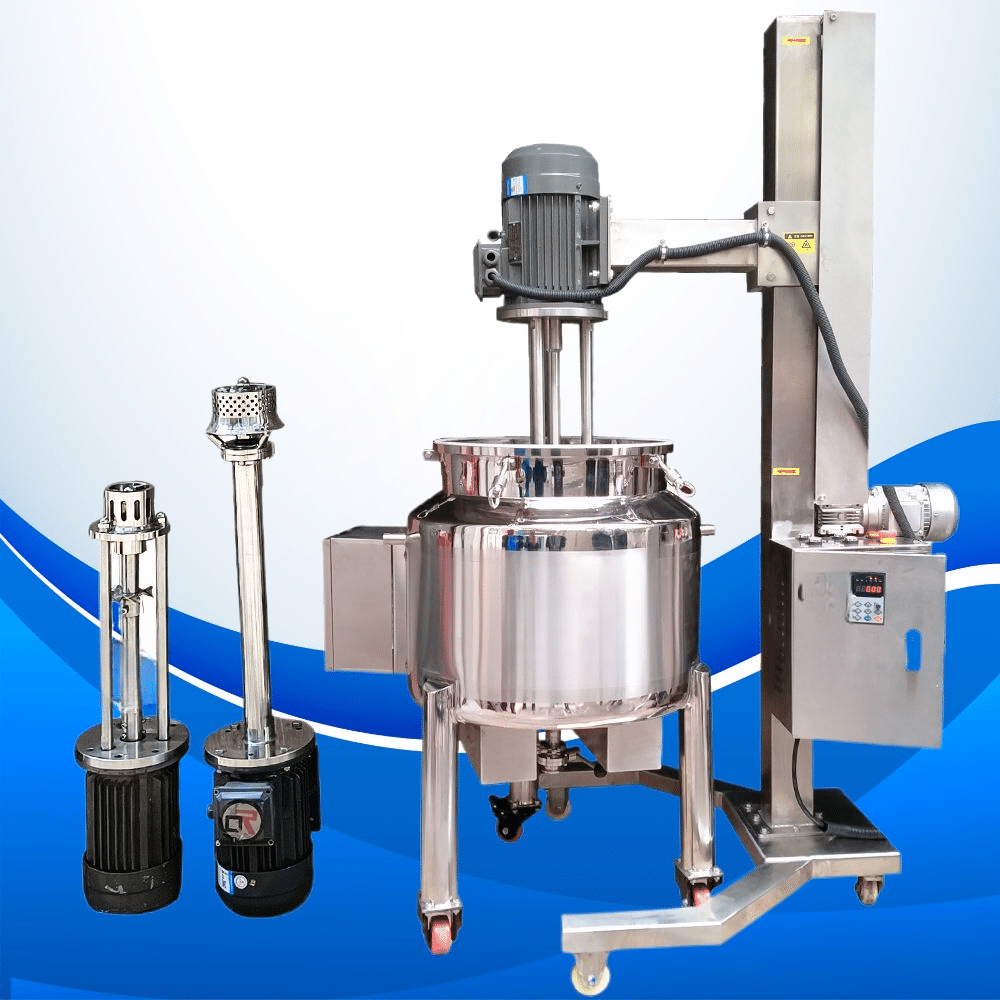

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

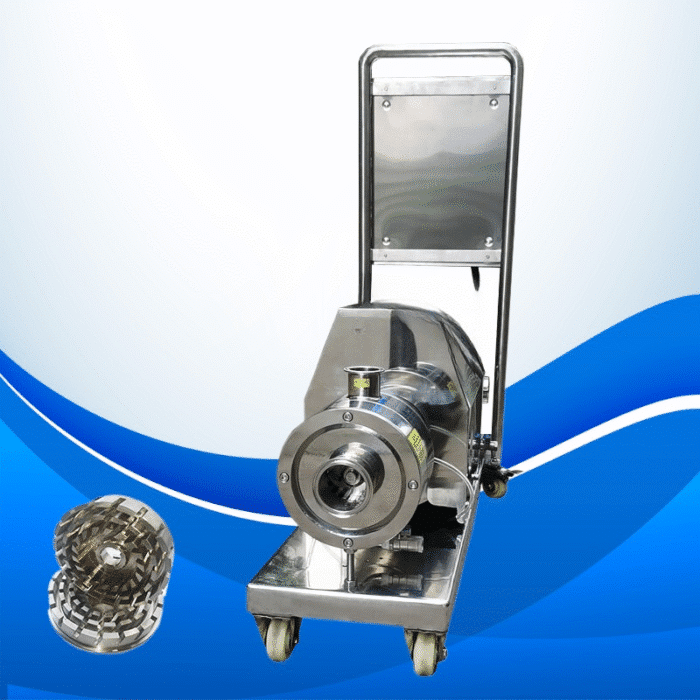

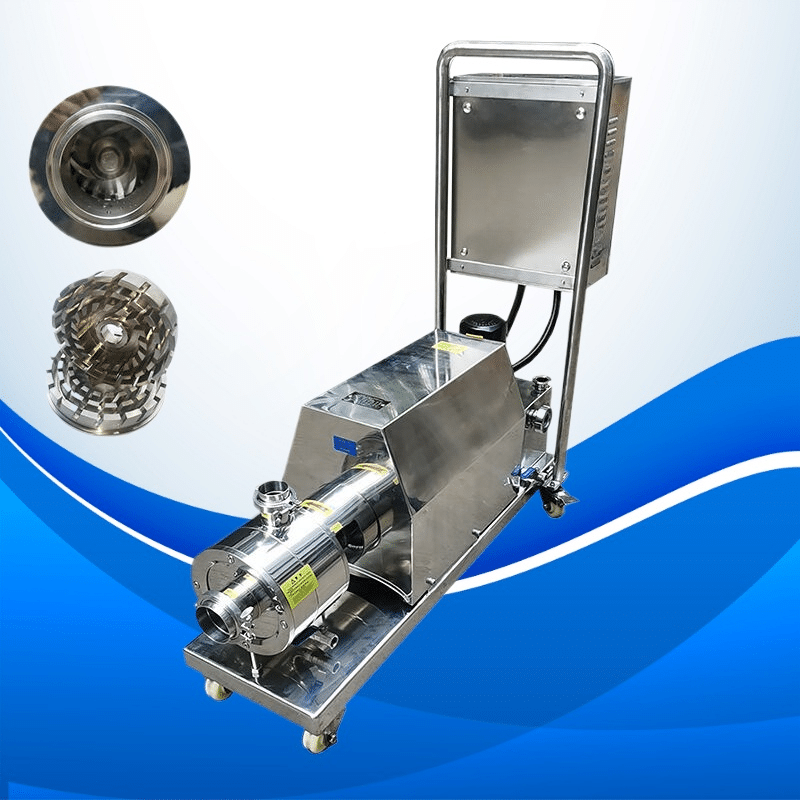

Easy to move and lift

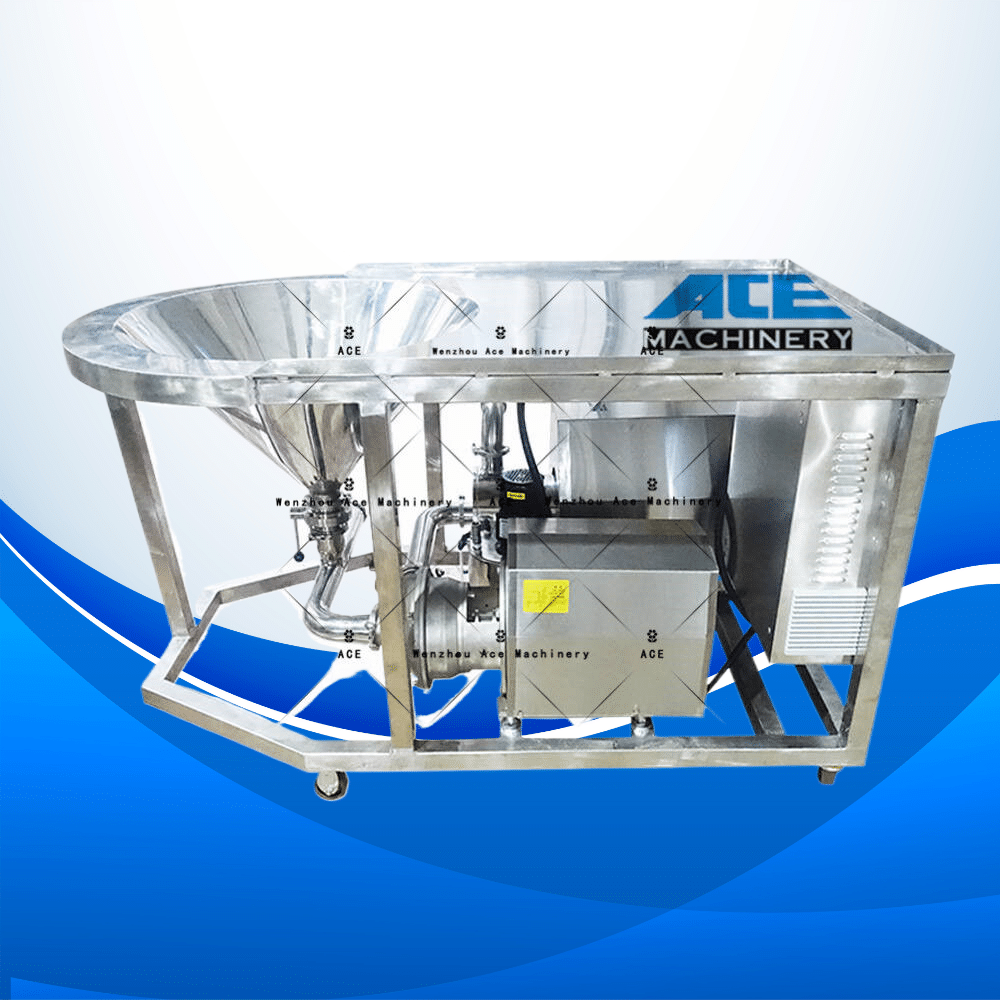

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

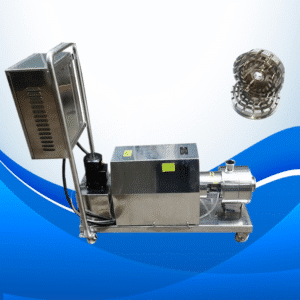

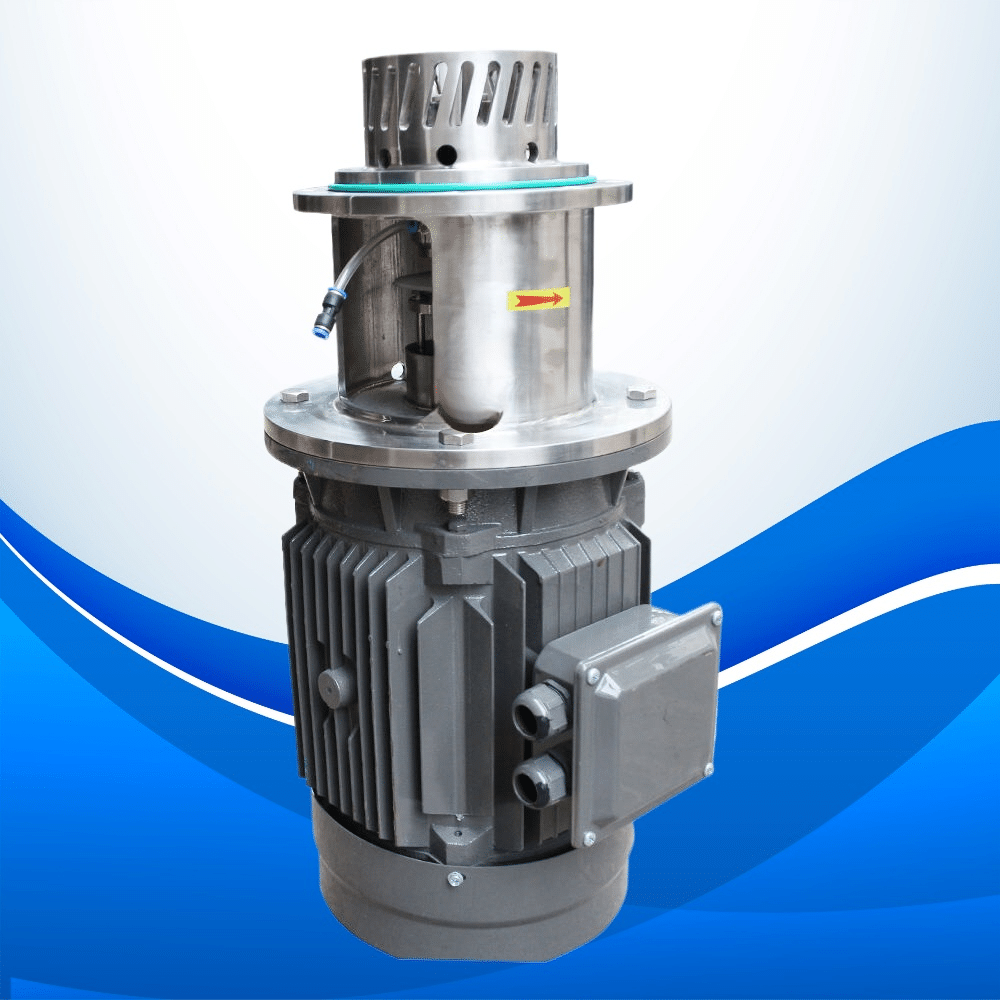

Our inline high-shear mixer is built for factories and test labs that need fast, fine mixing and cutting. Custom add-ons let you tweak the unit so it fits almost any job, from making creams to treating chemicals.

✅ Why Customers Choose It

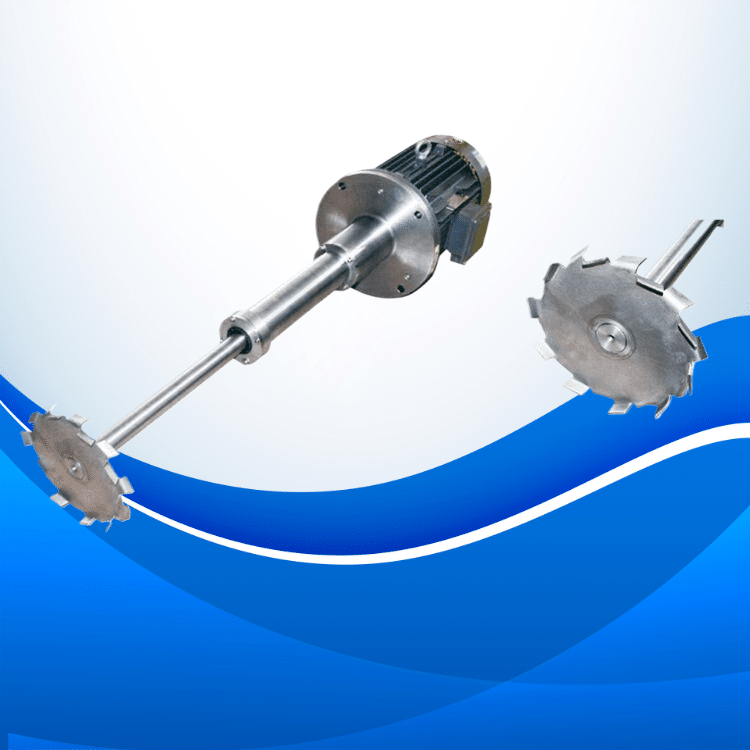

Best-In-Class Cutting Power

Droplets and particles are sliced down to microns in one pass, so jobs finish faster.

That repeatable quality is a must in pharma, cosmetics, food, and glue manufacturing.

Flexible Material Choices

Pick 316L or 304 stainless for the right level of corrosion resistance and cleanability.

Either grade meets food, drug, or industrial hygiene rules worldwide.

Wide Power and Voltage Options

Motor sizes range from 1.5 kW all the way up to 35 kW.

Voltages from 110 V to 600 V, single-phase or three-phase, match any plant feed.

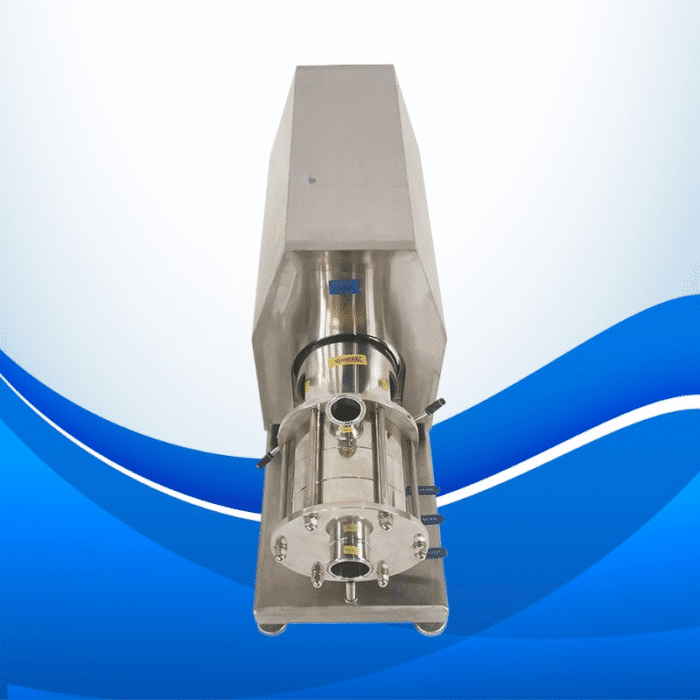

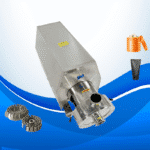

Inline or Closed Loop Ready

Drop it straight into the pipe for nonstop flow, easy CIP, or clean-room duty.

The small vertical or horizontal flange layout saves floor space without cutting output.

Scalable Setup, Lower Overall Cost

Start with a pilot-liter line and grow to tons per hour without redesigning.

The inline style trims the footprint and makes repairs quick, slashing total ownership cost.

🧪 Where You’ll See It

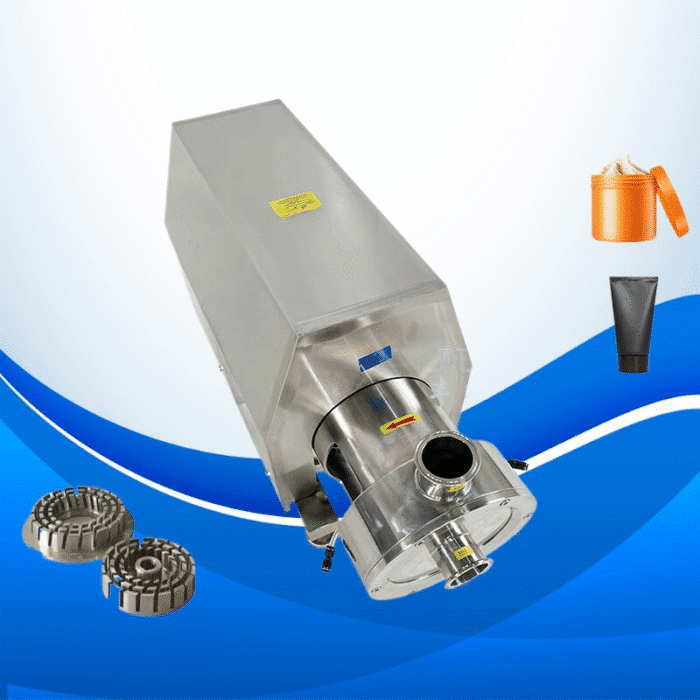

Emulsion Making

Whip up smooth oil-in-water creams, lotions, and batch cosmetics that feel great and have a tight droplet size.

Medicine Mixes

Keep active ingredients evenly blended in suspensions and ointments so every dose is spot-on.

Food & Drinks

Stir salad dressings, sauces, and dairy blends into a creamy, lump-free finish that customers love.

Paints & Coatings

Spread pigments evenly through paints and inks for solid color and performance from first swipe to last.

Adhesives & Polymers

Mix resins and fillers together well, boosting bond strength and giving materials a steady, repeatable feel.

🔧 Quick Specs

- Power: 1.5 kW | 3 kW | 7.5 kW | 15 kW | 22 kW | 35 kW

- Voltage: 110 V | 220 V | 380 V | 480 V | 600 V (single or three-phase)

- Material: Preferred 316L SS for pharma/food | budget-friendly 304 SS

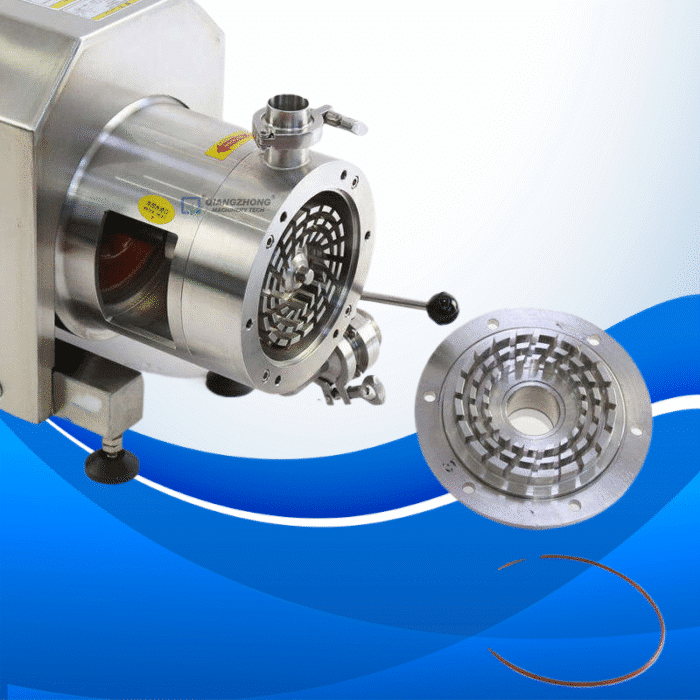

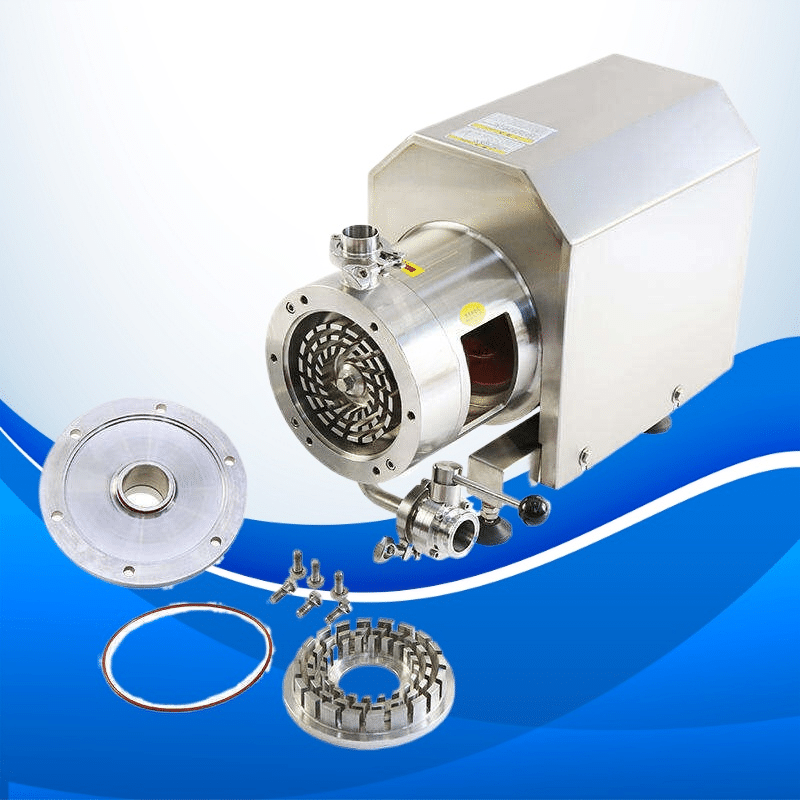

- Rotor-Stator: Interchangeable blades shaped for different thicknesses

- Mounting: inline flange or vertical immersion, with NPT/Tri-Clamp for CIP

- Flow Rate: 0.1 to 10 m3/h per pass, pick a model to match need

- Seals: mechanical or cartridge seals with CIP versions to stop leaks

🏭 Perfect Setups

Pilot Runs

Small footprint makes it ideal for lab tests, then scales up to full plant use.

Continuous Lines

Slip it straight into the pipeline for nonstop flow and fast cleanup between batches.

Batch Processing

Hook up the mixer to tanks and blend your emulsion or suspension in one smooth step.

Regulatory Compliance

Built from 316L stainless and sealed for clean rooms so it ticks all the FDA, EU, and USP Class VI boxes.

❓ Common Questions

1. Can it handle high-viscosity fluids?

Yes, models with bigger rotors and motors up to 35 kW tackle liquids that reach 100,000 cP with no problem.

2. Is it compliant with food/pharma standards?

Absolutely. 316L steel, sanitary polish, and CIP-ready seals work together to meet every food and drug rule.

3. What maintenance is required?

Just check the seals and rotor-stator set now and then. You can swap them out in about fifteen minutes when the time comes.

4. Is there a minimum batch size?

The mixer takes agitated batches as small as 10 L, or it runs a continuous line below 100 L/h without losing speed.

5. Can I get EU/UK electrical specs?

For sure—380 to 480 V three-phase options are ready for the European, Asian, and other worldwide plants.

🛒 Call to Action

Step up your mixing game with our inline high-shear mixer. It gives you spot-on blends, scales easily as your line grows, and comes with specs that fit your needs. Whether you’re trying out a new formula or fine-tuning an old one, this industrial-level machine cuts downtime and keeps every batch uniform.

Ready to Buy or Customize?

Give us a shout and well walk through your setup, pick the right model (1.5-35 kW, 110-600 V, 316L/304 SS), and send you a fast quote. Get cleaner, quicker, and steadier production—order your inline high-shear mixer today!