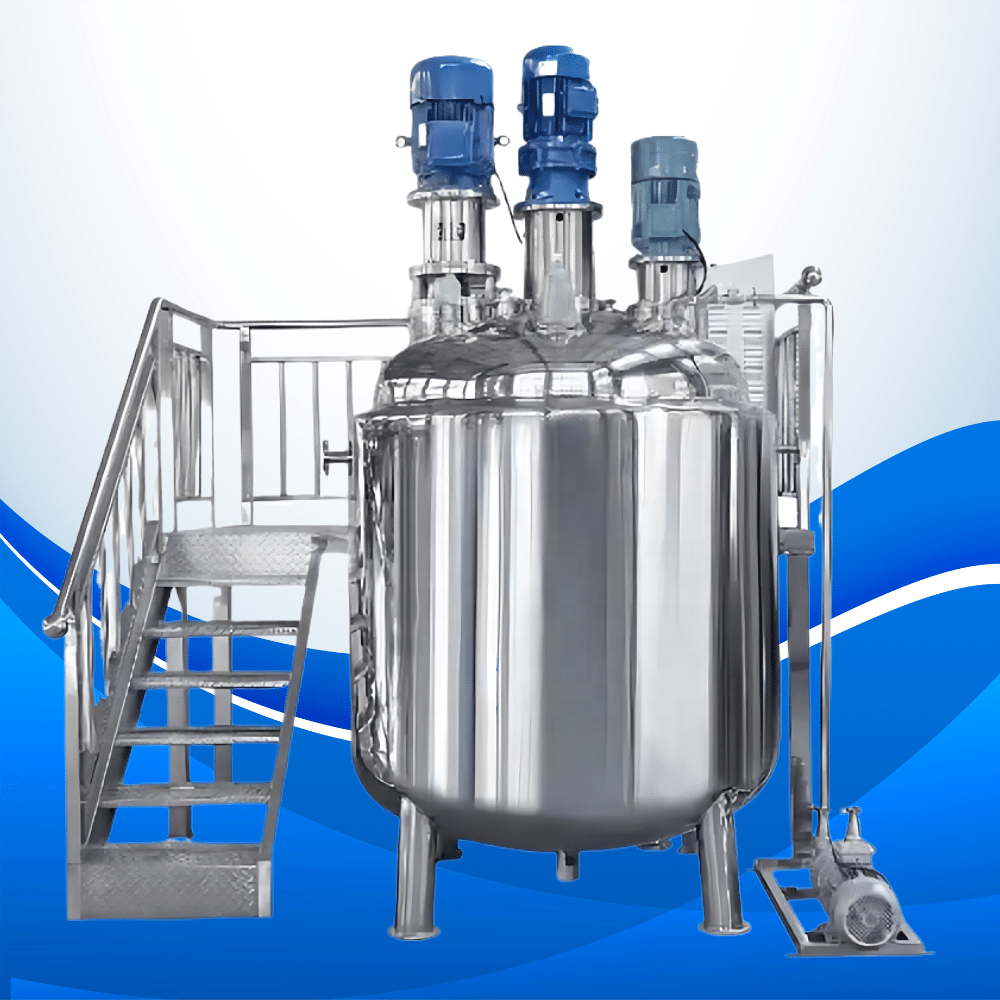

Product Description: Heating Jacket Mixing Tank

Meet the heating jacket mixing tank-a modern piece of equipment that heats and stirs materials at the same time. Whether your product is a thin liquid, a thick paste, or something in between, the tank gives you steady temperature control so everything blends evenly. It’s got a spot in food plants, drugmakers, chemical lines, and beauty factories, where speed, quality, and trust matter most.

Key Features and Advantages

Customizable Power Options

You pick a heating power between 1.5 kW and 55 kW, matching the tank exactly to your job. Because the range is broad, the system can grow as your orders grow.

Flexible Voltage Options

Wired for 110V to 600V, this tank slips into almost any shop without fuss, whether the power drops in a small outlet or hammers through a heavy industrial feed.

Durable Material Selection

You can order the drum in 316L or 304 stainless steel, both tough against rust and chemicals, so it stays clean and safe even under strict hygiene rules.

Steady Heat Where You Want It

The built-in heating jacket wraps evenly around the tank, so every bit of the mixture stays at the same temperature. That stops liquids from getting too hot, forming lumps, or breaking apart. Its crucial for delicate recipes that depend on a strict heat level to blend well.

Simple Controls

Thoughtful, easy-to-read controls let anyone on the team pick a target temperature and choose how fast to stir. Digital readouts show exactly what the tank is doing, so operators can glance and know there are no surprises.

Food Industry

Ideal for making sauces, jams, or drinks that need gentle heat and steady mixing without ruining the taste. Because the jacket keeps the temperature even, cooks never worry about burning the mix or cooking one spot more than another.

Pharmaceuticals

Critical when blending creams, ointments, or liquid drugs that must be warmed and stirred under tight control. Built from 316L stainless steel, the tank also passes the high-cleanliness rules that every modern lab and factory expects.

Chemical Processing

Lots of reactions speed up or slow down with temperature swings, so even heat is non-negotiable. The jackets uniform warmth lets chemists work with confidence, knowing their batches will come out the same every time.

Cosmetics Production

Lotion, serum, or hair-care line about to launch? A heating-jacket mixing tank creates a gentle, stable zone where active ingredients blend smoothly. No burning or settling means your finished products look and feel pro-grade.

Product Specifications

- Power: 1.5 to 55 kW (built to match your output)

- Voltage: 110 to 600 V (options for every workshop)

- Material: Choose 316L stainless (best for corrosive blends) or 304 stainless (tough yet pocket-friendlier)

- Capacity: Mini lab size to bulk batches available

- Control: Jacket holds temp within +-0.5 C all day

- Mix Speed: Dial in the stir rate your formula likes

- Safety: Overheat cut-off, auto shut-off, and loud temp alarm

Why Choose a Heating-Jacket Mixing Tank?

When the job demands steady heat and fast mixing, the tank gives you both without drama. Less burned product and no lumps mean shorter rework time and fewer rejects. Because every detail-from power to gauges-can be customized, you can scale gently or aggressively while still protecting product quality.

Pick between tough 316L stainless steel and the wallet-friendlier 304 grade, so you get the right material for your business without losing performance. Plus, with lots of power and voltage choices, the heating jacket mixing tank slides right into your current setup.

Call to Action: Customize Your Solution Today!

Want a dependable, high-performing heating jacket mixing tank? Get in touch and well chat about your needs and how we can tweak the tank just for you. Whether you work with food, drugs, chemicals, or cosmetics, our tanks mix and heat with precision and efficiency.

Common Questions

Q1: What material is best for my application?

If your product meets rough chemicals all the time, 316L gives you top-notch rust protection. For a more budget-friendly route, 304 stainless steel still offers solid strength and durability.

Q2: Can I drop the heating-jacket mixing tank into my current production line?

Yep! The heating-jacket tank is built to fit in lots of set-ups. With voltages from 110V all the way to 600V, it slips into most networks without a hitch.

Q3: How close does the temperature control stay to my set point?

The jacket heating works evenly around the walls, so you get steady heat and tamed numbers, perfect for sensitive blends.

Q4: Can you make a tank that matches my odd space or power demand?

For sure! We fully customize size, material, and wattage. Just reach out, and we’ll sketch a solution that fits your line.

Q5: What’s the easiest way to keep the heating-jacket tank running well?

A quick clean and look over the wires sometimes is all we ask. Control panels sit out in the open, and the walls wipe down fast.

Put a heating-jacket mixing tank on your floor and see smoother, more depend-able batches, day in, day out!