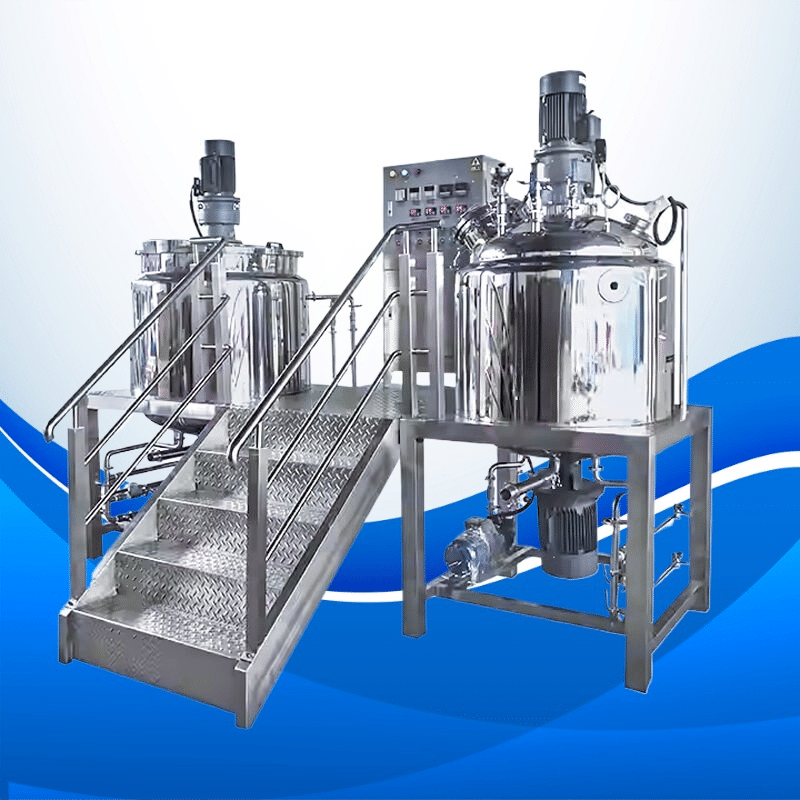

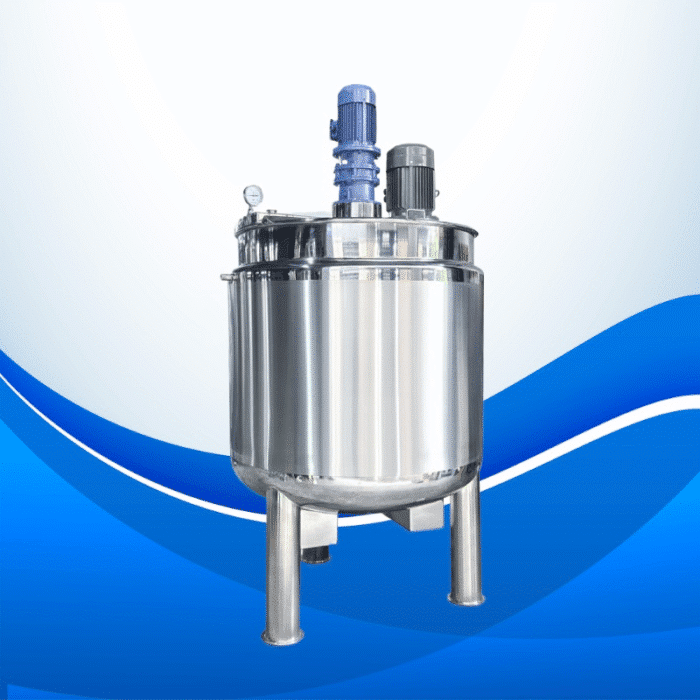

Emulsifying Mixing Homogenizer Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,700.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Looking for a mixing tank that really delivers? The emulsifying mixing homogenizer tank was built just for people like you. Its smart design blends, heats, and evenly breaks down ingredients all at once, saving you time and hassle. Whether you’re making creams, sauces, or chemical formulas, this unit promises the same high quality every batch.

Flexibility is its best feature. Select a motor from a mild 1.5 kW to a beefy 55 kW, choose any voltage from 110 V to 600 V, and pick either shiny 304 or tougher 316 L stainless steel. The clear digital controls talk you through the steps, so even new operators can run it with confidence. That means smoother texture, longer shelf life, and a line that runs calmer, cleaner, and faster.

Key Advantages

This emulsifying mixing homogenizer tank shines because it brings together several top mixing methods in one machine.

High-shear emulsification

High-shear emulsification uses a fast-spinning rotor to slash particles into tiny bits, turning oily and watery ingredients into silky, stable blends.

Powerful homogenization

Powerful homogenization then squeezes that mix under pressure, smoothing out anything left over. This step is what gives lotions, creams, and syrups their professional feel.

Precise temperature control

Precise temperature control matters, especially in pharmacies and salons. Built-in heating and cooling jackets let you dial in the exact degree you need, so proteins or active ingredients never singe or lump.

Vacuum mix containers

Vacuum mix containers stop air bubbles from forming while ingredients blend, a must for luxury cosmetics and delicate food lines. Wherever quality counts, a smooth, bubble-free product separates the best from the rest.

Wire in any mix of power between 1.5 kW and 55 kW and pick voltages from 110 V to 600 V. This flexibility matches local grids and scale-up needs, so factories never get slowed by mismatched mains.

Choose either 304 or 316L stainless and the body arrives with every weld polished, every corner easy to scrub. The material fights rust and meets hygiene laws in every market, from pharmacies to chocolate plants.

Plumb the tank into a CIP or SIP loop and clean-in-place chores trim from hours to minutes. Continuous load cycles keep running costs low, while quick service panels let techs swap seals or gauges without tearing down a line.

WHERE YOU’LL SEE IT

1. In Cosmetics labs

The tank churns out creams, gels, and shampoos with needle-fine particles and zero air clouds.

2. Hospitals and clinics

Hospitals and clinics trust the system for ointments, syrups, and sterile suspensions because it heats, cools, and cleans on command.

3. Chefs and bottlers

Chefs and bottlers use the same set-up to whip sauces, dressings, dairy drinks, and meal shakes, while flavor samples stay fresh for months.

4. Chemical Processing

This emulsifier is perfect for working with tough mixtures such as adhesives, resins, paints, and heavy-duty lubricants. Its powerful design handles thick liquids easily, so every batch comes out uniform and ready to use.

Whether you want to boost output or tweak a recipe, the machine makes sure each new drum meets your quality targets.

Specifications and Customization

To fit your setup exactly, our emulsifying-homogenizer tanks offer a long list of options:

- Power: 1.5 kW, 3 kW, 7.5 kW, 11 kW, 18.5 kW, and even 55 kW for big plants.

- Voltage: 110 V, 220 V, 380 V, 415 V, 480 V, and 600 V, so you can plug it in almost anywhere.

- Materials: choose food-safe 304 stainless or extra-tough 316L steel.

- Capacity: from a handy 50 L up to a full 5,000 L.

- Speed: adjustable from zero to 3,000 RPM using variable-frequency drive.

- Extras: vacuum hookup, sterilizable CIP/SIP system, jacketed heating, scraper blades, and optional PLC touch screen.

Every unit is built to your order. Whether you need a stand-alone mixer or gear that fits a bigger line, our engineers walk you through the detail.

Why Choose Us?

With more than ten years in high-tech mixing, we know what plants really need. Each tank earns CE and ISO stamps, and we test tough before it leaves the factory. A sharp R&D crew and worldwide support let us ship on time, back up every product, and solve issues fast.

Every tank leaves our factory after thorough testing and comes with a full set of guides, hands-on training if needed, and optional help from our team when it is time to install.

Call to Action & FAQ

Want to boost your production and get consistent results? Reach out for a free quote, and we will design a mixing tank that fits your needs exactly.

Common Questions

Q1: Can I set the voltage and power to match my local grid?

Absolutely. We supply units from 110V to 600V and from 1.5KW to 55KW.

Q2: Who uses these tanks?

People in cosmetics, pharma, food, chemicals and lots of other fields.

Q3: What’s the typical delivery time?

Standard models ship in 15–20 days; custom-builds take 20–30 days.

Q4: Do you send a crew for installation?

Yes, on-site setup and training are available for anyone who wants them.